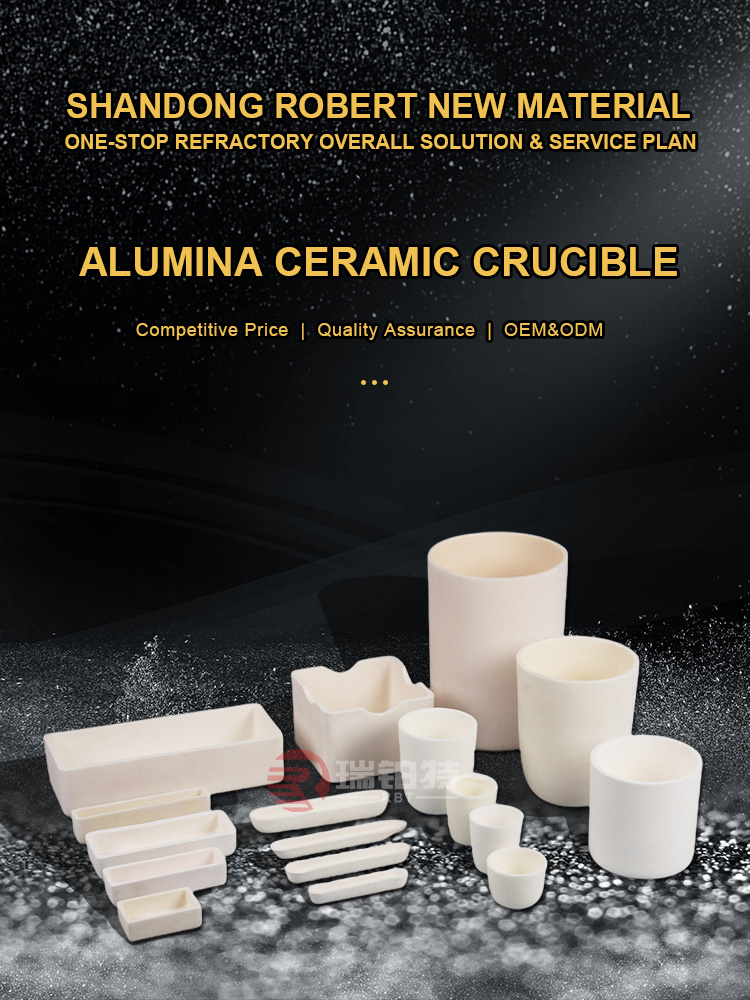

Sebopi sa Alumina Ceramic

Tlhahisoleseding ea Sehlahisoa

Sekoahelo sa ceramic sa Aluminake setshelo sa laboratori se nang le mocheso o phahameng le se sa senyeheng ke mafome se entsoeng ka alumina e hloekileng haholo (Al₂O₃) e le thepa e tala ea mantlha ka ts'ebetso e itseng. E sebelisoa haholo libakeng tsa liteko tsa mocheso o phahameng masimong a k'hemistri, tšepe le saense ea thepa.

Likaroloana:

Bohloeki bo phahameng:Bohloeki ba alumina ka har'a li-crucible tsa ceramic tsa alumina hangata bo fihla ho 99% kapa ho feta, ho netefatsa botsitso le ho se sebetse hantle ha lik'hemik'hale mochesong o phahameng.

Ho hanyetsa mocheso o phahameng:Sebaka sa eona sa ho qhibiliha se phahame ho fihlela ho 2050℃, mocheso oa tšebeliso ea nako e telele o ka fihla ho 1650℃, 'me e ka mamella mocheso o phahameng ho fihlela ho 1800℃ bakeng sa tšebeliso ea nako e khuts'oane.

Khanyetso ea ts'enyeho:E na le khanyetso e matla khahlanong le lintho tse senyang tse kang li-acid leli-alkali, 'me li ka boloka ts'ebetso e tsitsitseng libakeng tse fapaneng tse thata tsa lik'hemik'hale.

Conductivity e phahameng ea mocheso:E ka tsamaisa le ho hasanya mocheso ka potlako, ea laola mocheso oa liteko ka katleho, le ho ntlafatsa katleho ea liteko.

Matla a phahameng a mechini:E na le matla a phahameng a mechini mme e ka mamella khatello e kholo ea kantle ntle le ho senyeha habonolo.

Koefficient e tlase ea katoloso ea mocheso:E fokotsa kotsi ea ho petsoha le tšenyo e bakoang ke katoloso le ho honyela ha mocheso.

Ho bonolo ho e hloekisa:Bokaholimo bo boreleli ebile bo bonolo ho bo hlwekisa ntle le ho silafatsa sampole, ho netefatsa ho nepahala ha liphetho tsa liteko.

Litšoantšo tse qaqileng

| Bohloeki | 95%/99%/99.7%/99.9% |

| 'Mala | Bosweu, lenaka la tlou le mosehla |

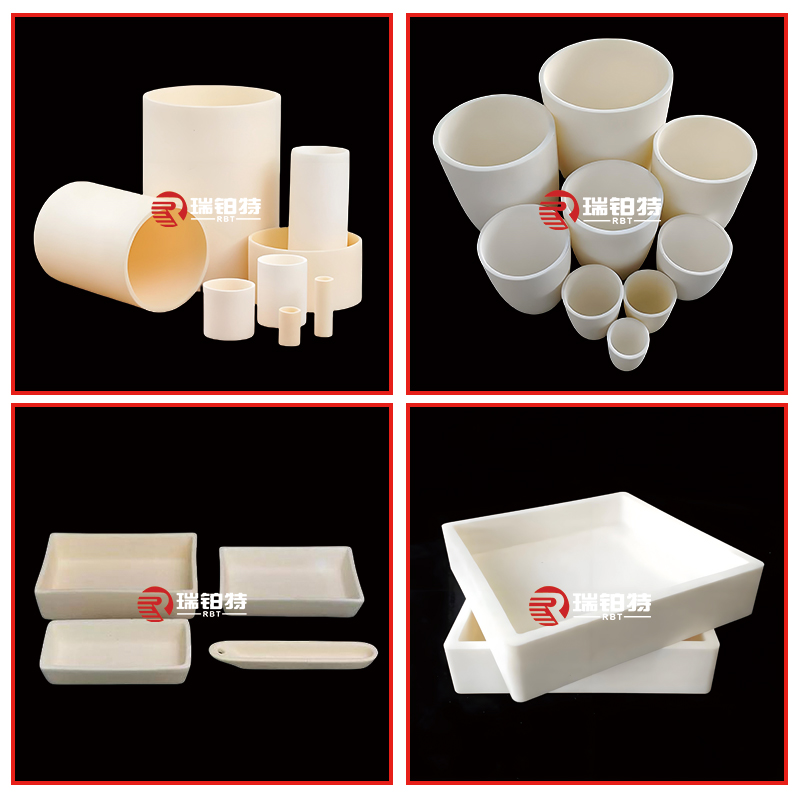

| Sebopeho | Arc/Square/Rectangle/Silindara/Sekepe |

Lethathamo la Sehlahisoa

| Thepa | Alumina | ||||

| Matlo | Diyuniti | AL997 | AL995 | AL99 | AL95 |

| Alumina | % | 99.70% | 99.50% | 99.00% | 95% |

| 'Mala | -- | lvory | lvory | lvory | lvory&White |

| Ho kenella ha metsi | -- | E thibelang peterole | E thibelang peterole | E thibelang peterole | E thibelang peterole |

| Botenya | g/cm³ | 3.94 | 3.9 | 3.8 | 3.75 |

| Ho otloloha | -- | 1‰ | 1‰ | 1‰ | 1‰ |

| Bothata | Sekala sa Mohs | 9 | 9 | 9 | 8.8 |

| Ho Monya Metsi | -- | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 |

| Matla a ho Tenyetseha (Tloaelehileng 20ºC) | Mpa | 375 | 370 | 340 | 304 |

| E hatellangMatla (Tloaelehileng 20ºC) | Mpa | 2300 | 2300 | 2210 | 1910 |

| Koefficient eaThermal Katoloso (25ºC ho isa ho 800ºC) | 10-6/ºC | 7.6 | 7.6 | 7.6 | 7.6 |

| DielectricMatla (Botenya ba 5mm) | AC-kv/mm | 10 | 10 | 10 | 10 |

| Tahlehelo ea Dielectric 25ºC@1MHz | -- | <0.0001 | <0.0001 | 0.0006 | 0.0004 |

| DielectricKamehla | 25ºC@1MHz | 9.8 | 9.7 | 9.5 | 9.2 |

| Ho hanyetsa molumo (20ºC) (300ºC) | Ω·cm³ | >1014 2*1012 | >1014 2*1012 | >1014 4*1011 | >1014 2*1011 |

| Ts'ebetso ea nako e telele mocheso | ºC | 1700 | 1650 | 1600 | 1400 |

| ThermalHo khanna motlakase (25ºC) | W/m·K | 35 | 35 | 34 | 20 |

Tlhaloso

| Boholo ba Motheo ba Sebōpi sa Cylindrical | |||

| Bophara(mm) | Bolelele(mm) | Botenya ba lebota | Dikahare (ml) |

| 15 | 50 | 1.5 | 5 |

| 17 | 21 | 1.75 | 3.4 |

| 17 | 37 | 1 | 5.4 |

| 20 | 30 | 2 | 6 |

| 22 | 36 | 1.5 | 10.2 |

| 26 | 82 | 3 | 34 |

| 30 | 30 | 2 | 15 |

| 35 | 35 | 2 | 25 |

| 40 | 40 | 2.5 | 35 |

| 50 | 50 | 2.5 | 75 |

| 60 | 60 | 3 | 130 |

| 65 | 65 | 3 | 170 |

| 70 | 70 | 3 | 215 |

| 80 | 80 | 3 | 330 |

| 85 | 85 | 3 | 400 |

| 90 | 90 | 3 | 480 |

| 100 | 100 | 3.5 | 650 |

| 110 | 110 | 3.5 | 880 |

| 120 | 120 | 4 | 1140 |

| 130 | 130 | 4 | 1450 |

| 140 | 140 | 4 | 1850 |

| 150 | 150 | 4.5 | 2250 |

| 160 | 160 | 4.5 | 2250 |

| 170 | 170 | 4.5 | 3350 |

| 180 | 180 | 4.5 | 4000 |

| 200 | 200 | 5 | 5500 |

| 220 | 220 | 5 | 7400 |

| 240 | 240 | 5 | 9700 |

| Boholo ba Motheo ba Sebopi se Khutšoanyane | |||||

| Bolelele(mm) | Bophara(mm) | Bolelele(mm) | Bolelele(mm) | Bophara(mm) | Bolelele(mm) |

| 30 | 20 | 16 | 100 | 60 | 30 |

| 50 | 20 | 20 | 100 | 100 | 30 |

| 50 | 40 | 20 | 100 | 100 | 50 |

| 60 | 30 | 15 | 110 | 80 | 40 |

| 75 | 52 | 50 | 110 | 110 | 35 |

| 75 | 75 | 15 | 110 | 80 | 40 |

| 75 | 75 | 30 | 120 | 75 | 40 |

| 75 | 75 | 45 | 120 | 120 | 30 |

| 80 | 80 | 40 | 120 | 120 | 50 |

| 85 | 65 | 30 | 140 | 140 | 40 |

| 90 | 60 | 35 | 150 | 150 | 50 |

| 100 | 20 | 15 | 200 | 100 | 25 |

| 100 | 20 | 20 | 200 | 100 | 50 |

| 100 | 30 | 25 | 200 | 150 | 5 |

| 100 | 40 | 20 | |||

| Boholo ba Motheo ba Arc Crucible | ||||

| Bophara bo Holimo.(mm) | Bophara ba Motheo.(mm) | Bolelele(mm) | Botenya ba lebota (mm) | Dikahare (ml) |

| 25 | 18 | 22 | 1.3 | 5 |

| 28 | 20 | 27 | 1.5 | 10 |

| 32 | 21 | 35 | 1.5 | 15 |

| 35 | 18 | 35 | 1.7 | 20 |

| 36 | 22 | 42 | 2 | 25 |

| 39 | 24 | 49 | 2 | 30 |

| 52 | 32 | 50 | 2.5 | 50 |

| 61 | 36 | 54 | 2.5 | 100 |

| 68 | 42 | 80 | 2.5 | 150 |

| 83 | 48 | 86 | 2.5 | 200 |

| 83 | 52 | 106 | 2.5 | 300 |

| 86 | 49 | 135 | 2.5 | 400 |

| 100 | 60 | 118 | 3 | 500 |

| 88 | 54 | 145 | 3 | 600 |

| 112 | 70 | 132 | 3 | 750 |

| 120 | 75 | 143 | 3.5 | 1000 |

| 140 | 90 | 170 | 4 | 1500 |

| 150 | 93 | 200 | 4 | 2000 |

Likopo

1. Kalafo ea mocheso o phahameng:Li-crucible tsa letsopa tsa Alumina li ka mamella tšebeliso ea nako e telele libakeng tse nang le mocheso o phahameng 'me li na le khanyetso e ntle ea mocheso. Ka hona, li sebelisoa haholo masimong a kalafo ea mocheso o phahameng, joalo ka ho sintering, kalafo ea mocheso, ho qhibiliha, ho annealing le lits'ebetso tse ling.

2. Tlhahlobo ea lik'hemik'hale:Li-crucible tsa ceramic tsa Alumina li na le khanyetso e ntle ea ho bola 'me li ka sebelisoa bakeng sa tlhahlobo le karabelo ea li-reagent tse fapaneng tsa lik'hemik'hale, joalo ka litharollo tsa asiti le alkali, li-reagent tsa redox, li-reagent tsa tlhaho, jj.

3. Ho qhibilihisa tšepe:Ho hanyetsa mocheso o phahameng le botsitso bo botle ba lik'hemik'hale ba li-crucible tsa ceramic tsa alumina ho etsa hore li be molemo lits'ebetsong tsa ho qhibilihisa le ho lahla tšepe, tse kang ho qhibilihisa le ho lahla aluminium, tšepe, koporo le litšepe tse ling.

4. Tšepe ea phofo:Li-crucible tsa ceramic tsa Alumina li ka sebelisoa ho lokisa lisebelisoa tse fapaneng tsa tšepe le tse seng tsa tšepe tsa tšepe, tse kang tungsten, molybdenum, tšepe, koporo, aluminium, jj.

5. Tlhahiso ea Thermocouple:Li-crucible tsa ceramic tsa Alumina li ka sebelisoa ho etsa lipeipi tsa tšireletso ea ceramic tsa thermocouple le li-cores tse sireletsang mocheso le likarolo tse ling ho netefatsa botsitso le ho nepahala ha li-thermocouple.

Tlhahlobo ea laboratori le ea indasteri

Ho qhibilihisa tšepe

Tšepe ea phofo

Tlhahiso ea thermocouple

Sephutheloana le Ntlo ea polokelo

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e fumaneha Motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa e hanyetsang. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea ontong, theknoloji le thepa e hanyetsang kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a tekheniki a matla, boleng bo botle ba sehlahisoa, le botumo bo botle. Feme ea rona e akaretsa lihekthere tse fetang 200 'me tlhahiso ea selemo le selemo ea thepa e hanyetsang e bōpehileng joaloka e ka ba lithane tse 30000 'me thepa e hanyetsang e sa bōpehang joaloka e hanyetsang ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa e hanyetsang li kenyelletsa:thepa e hanyetsang alkaline; thepa e hanyetsang silicon ea aluminium; thepa e sa bōpehang e hanyetsang; thepa e thibelang mocheso e thibelang mocheso; thepa e khethehileng e thibelang; thepa e sebetsang e thibelang bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Khafetsa

Na u hloka thuso? Etsa bonnete ba hore u etela liforamo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, fektheri ea rona e ikhethile ka ho hlahisa thepa e hanyetsang ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ea kamora thekiso.

Bakeng sa ts'ebetso e 'ngoe le e 'ngoe ea tlhahiso, RBT e na le sistimi e felletseng ea QC bakeng sa sebopeho sa lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa, 'me setifikeiti sa boleng se tla romelloa le thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho latela bongata, nako ea rona ea ho tlisa thepa e fapane. Empa re tšepisa ho e romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ehlile, re fana ka disampole tsa mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e ntle ka ho fetisisa ho latela boemo ba hau.

Re ntse re etsa thepa e hanyetsang mocheso ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le boiphihlelo bo bongata, re ka thusa bareki ho rala li-kiln tse fapaneng le ho fana ka tšebeletso ea ho emisa hang feela.