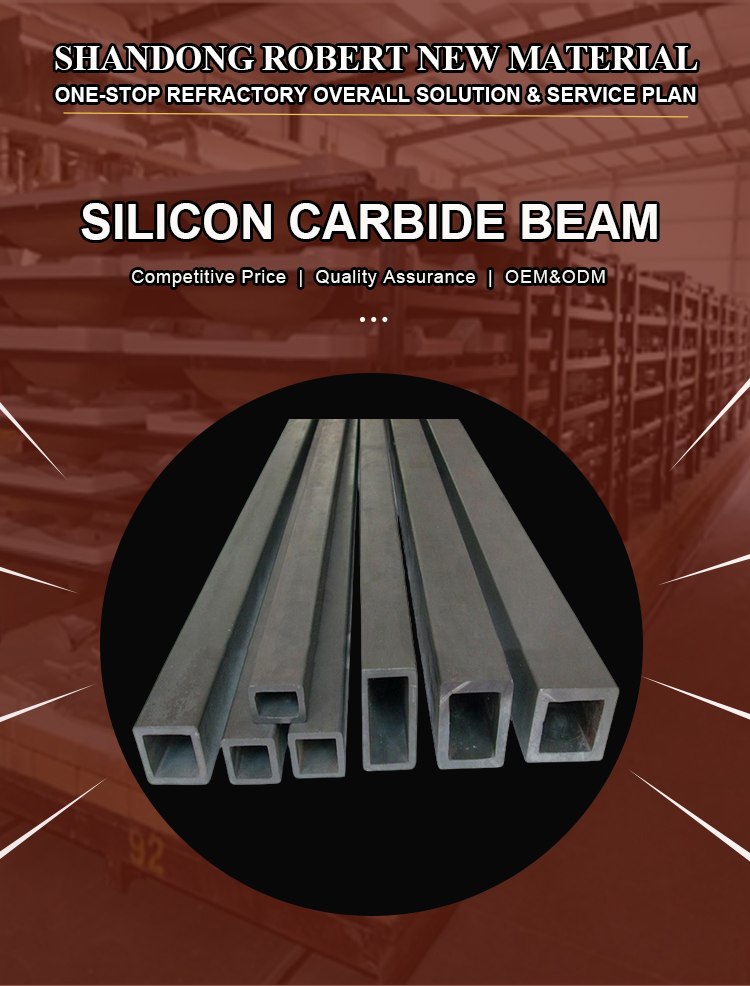

Theko e Molemohali ea Refractory Reaction Bonded Silicon Carbide Ceramic Beam bakeng sa Rbsic Batts le Sisic Beam

Hammoho le filosofi ea khoebo ea "Client-Oriented", ts'ebetso e matla ea taolo ea boleng bo holimo, lihlahisoa tse holimo tsa tlhahiso hammoho le sehlopha se matla sa R&D, re lula re fana ka lihlahisoa tsa boleng bo holimo, litharollo tse ikhethang le litšenyehelo tse matla bakeng sa Theko e Ntle bakeng sa Refractory Reaction Bonded Silicon Carbide Ceramic Beam Ka hona, bakeng sa Rbsic Beams ho tsoa ho li-Batts tse fapaneng li khona ho kopana. bareki ba fapaneng. Hopola ho fumana sebaka sa rona sa marang-rang ho sheba lintlha tse ling tse ngata ho tsoa lihlahisoa tsa rona.

Hammoho le filosofi ea khoebo ea "Client-Oriented", ts'ebetso e matla ea taolo ea boleng bo holimo, lihlahisoa tse phahameng tsa tlhahiso hammoho le sehlopha se matla sa R&D, re lula re fana ka lihlahisoa tsa boleng bo holimo, litharollo tse ikhethang le litšenyehelo tse mabifi bakeng sa.Ceramic Roller le Silicon Carbide Kiln Shelves, Lihlahisoa tsa rona li tsejoa ka ho pharaletseng ebile li tšeptjoa ke basebelisi 'me li ka kopana le litlhoko tse tsoelang pele tsa moruo le tsa sechaba. Re amohela bareki ba bacha le ba khale ba tsoang mekhoeng eohle ea bophelo ho ikopanya le rona bakeng sa likamano tsa nako e tlang tsa khoebo le ho fihlela katleho e tšoanang!

Tlhahisoleseding ya Sehlahiswa

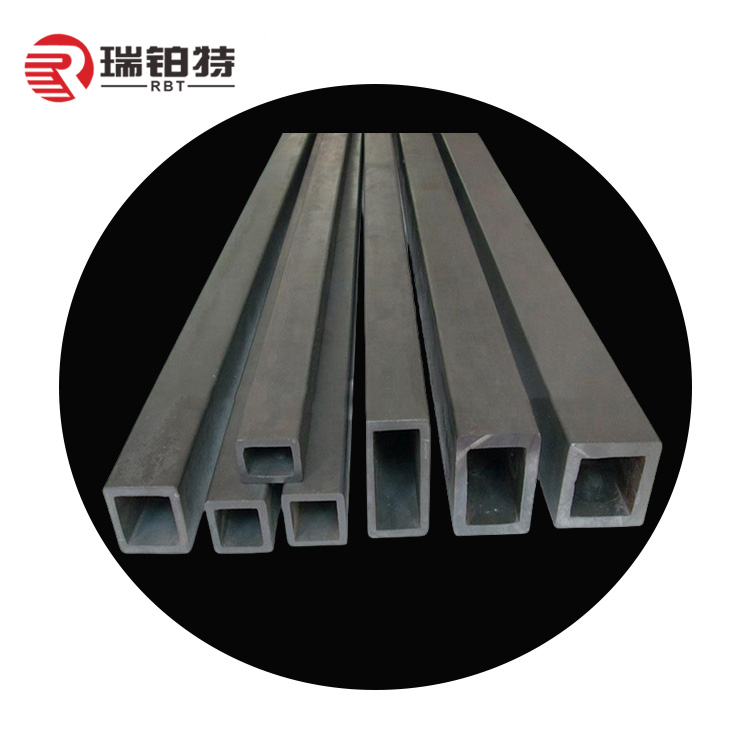

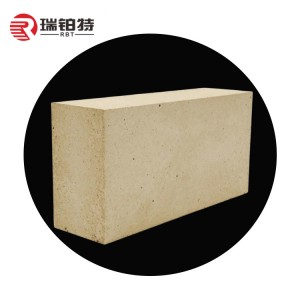

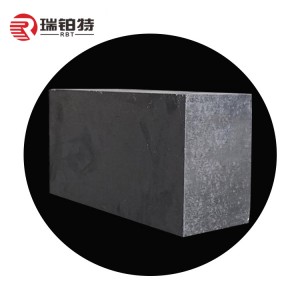

Lithako tsa silicon carbidee na le bokhoni bo botle ba ho jara mocheso o phahameng, botsitso bo botle ba sebopeho, le matla a anti-oxidation le anti-corrosion. Ba na le nako e telele ea tšebeletso (ka tlase ho likhato tse 1380) 'me ba ke ke ba robeha ka tšohanyetso, ba ke ke ba silafala kapa ba senyeha,' me ba ke ke ba silafatsa lihlahisoa tse chesitsoeng. Li loketse maballo a meralo ea meroalo ka har'a libotlolo tsa likotopo, libotlolo tsa shuttle, li-roller tse nang le likarolo tse peli le liotlolo tse ling tsa indasteri.

Likaroloana

1. Khanyetso e phahameng ea abrasion

2. Matla a phahameng a matla

3. Ha ho deformation tlas'a mocheso o phahameng

4. Boemo bo phahameng ba ho mamella mocheso 1650 degree celsius

5. Ho hanyetsa kutu

6. Matla a phahameng a ho khumama tlas'a tekanyo ea 1100: 100-120MPA

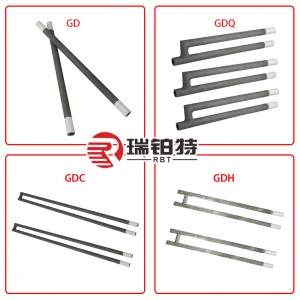

Lintlha Litšoantšo

Liraka tsa Kiln

Index ea Lihlahisoa

| Reactive Sintering Silicon Carbide Beam | ||

| Ntho | Yuniti | Lintlha |

| Mocheso o Phahameng oa Kopo | ℃ | ≤1380 |

| Botenya | g/cm3 | ~3.02 |

| Open Porosity | % | ≤0.1 |

| Matla a Kobehang | Mpa | 250(20℃); 280(1200℃) |

| Modulus ea Elastictiy | GPA | 330(20℃); 300(1200℃) |

| Thermal Conductivity | W/mk | 45(1200℃) |

| Mocheso oa Katoloso ea Mocheso | K-1*10-6 | 4.5 |

| Bothata ba Moh | 9.15 | |

| Acid Alkaline-Bopaki | E kgabane | |

| Ho Jara Bokhoni ba Mabala a RBSiC(SiSiC). | ||||||

| Boholo ba Karolo (mm) | Lerako Botenya (mm) | Kenyellelitsoe Loading(kg.m/L) | Tlamelo e Abuoang ka Ka mokhoa o Tšoanang(kg.m/L) | |||

| B Lehlakore | H Lehlakoreng | W Lehlakore | H Lehlakoreng | W Lehlakore | H Lehlakoreng | |

| 30 | 30 | 5 | 74 | 74 | 147 | 147 |

| 30 | 40 | 5 | 117 | 95 | 235 | 190 |

| 40 | 40 | 6 | 149 | 149 | 298 | 298 |

| 50 | 50 | 6 | 283 | 283 | 567 | 567 |

| 50 | 60 | 6 | 374 | 331 | 748 | 662 |

| 50 | 70 | 6 | 473 | 379 | 946 | 757 |

| 60 | 60 | 7 | 481 | 481 | 962 | 962 |

| 80 | 80 | 7 | 935 | 935 | 1869 | 1869 |

| 100 | 100 | 8 | 1708 | 1708 | 3416 | 3416 |

| 110 | 110 | 10 | 2498 | 2498 | 4997 | 4997 |

Kopo

Maballo a silicon carbide a loketse ka ho khetheha ho sebelisoa e le liforeimi tse jereng meroalo ka har'a libotlolo tsa kotopo, li-shuttle kilns, li-rolara tse habeli le lisebelisoa tse ling tsa indasteri. Ke thepa ea ka tlung e loketseng bakeng sa porcelain ea motlakase e matla haholo, porcelain ea sanitary, khalase e khanyang, lisebelisoa tsa refractory le liindasteri tse ling. Nako ea bophelo ke makhetlo a 'maloa ho feta a lisebelisoa tse ling. (ka tlase ho 1680 ℃) e ka sebelisoa makhetlo a fetang 100.

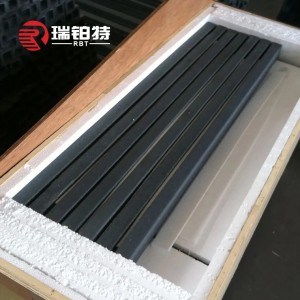

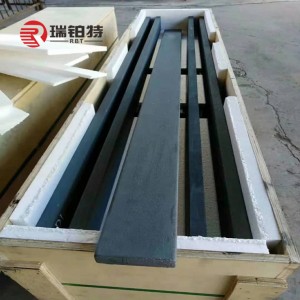

Sephutheloana le Bobolokelo

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e sebakeng sa Zibo City, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea lintho tse refractory. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea sebōpi, thekenoloji, le thepa ea ho rekisa kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a matla a tekheniki, boleng bo botle ba sehlahisoa le botumo bo botle.Feme ea rona e na le lihekthere tse fetang 200 mme tlhahiso ea selemo le selemo ea thepa e bōpehileng joaloka lithane tse ka bang 30000 'me thepa ea refractory e sa bopehang ke lithane tse 12000.

Lihlahisoa tsa rona tsa mantlha tsa thepa ea refractory li kenyelletsa:lisebelisoa tsa alkaline refractory; lisebelisoa tsa aluminium silicon refractory; thepa e sa bōpehang refractory; lisebelisoa tse thibelang mocheso oa mocheso; thepa e khethehileng refractory; lisebelisoa tse sebetsang tsa refractory bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lihlahisoa tsa Robert li sebelisoa haholo lioping tse nang le mocheso o phahameng joalo ka litšepe tse se nang ferrous, tšepe, thepa ea kaho le kaho, lik'hemik'hale, matla a motlakase, ho chesoa ha litšila le kalafo ea litšila tse kotsi. Li boetse li sebelisoa lits'ebetsong tsa tšepe le tsa tšepe tse kang ladles, EAF, blast furnaces, converters, lionto tsa coke, libono tse chesang tse chesang; libono tse se nang ferrous metallurgical tse kang li-reverberator, libopi tse fokotsang, libōpi tse phatlohang, le libōpi tsa rotary; liindasteri tsa thepa ea kaho tse kang liipone tsa likhalase, liipone tsa samente, le liipone tsa ceramic; li-kilns tse ling tse kang li-boilers, li-incinerators tsa litšila, sebōpi se halikiloeng, tse fihletseng liphello tse ntle ha li sebelisoa. Lihlahisoa tsa rona li romelloa ka ntle ho Asia Boroa-bochabela, Asia Bohareng, Bochabela bo Hare, Afrika, Europe, Amerika le linaheng tse ling, 'me e thehile motheo o motle oa tšebelisano-'moho le likhoebo tse ngata tse tsebahalang tsa tšepe. Basebetsi bohle ba Robert ba labalabela ka tieo ho sebetsa le uena bakeng sa boemo ba win-win.

Lipotso Tse Botsoang Hangata

U hloka thuso? Etsa bonnete ba hore u etela liforomo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Na u moetsi kapa mohoebi?

Re moetsi oa 'nete, feme ea rona e khethehile ho hlahisa thepa ea refractory ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ka mor'a ho rekisa.

U laola boleng ba hau joang?

Bakeng sa ts'ebetso e 'ngoe le e' ngoe ea tlhahiso, RBT e na le tsamaiso e feletseng ea QC bakeng sa metsoako ea lik'hemik'hale le thepa ea 'mele. 'Me re tla hlahloba thepa,' me setifikeiti sa boleng se tla romelloa ka thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Nako ea hau ea ho fihla ke mang?

Ho itšetlehile ka bongata, nako ea rona ea ho fana e fapane. Empa re tšepisa ho romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

O fana ka mehlala ea mahala?

Ha e le hantle, re fana ka mehlala ea mahala.

A na re ka etela k'hamphani ea hau?

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

MOQ ke eng bakeng sa taelo ea teko?

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e molemohali ho latela boemo ba hau.

Ke hobane'ng ha u re khetha?

Re 'nile ra etsa thepa ea refractory ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le phihlelo e ruileng, re ka thusa bareki ho rala li-kilns tse fapaneng le ho fana ka ts'ebeletso e le 'ngoe.

Hammoho le filosofi ea khoebo ea "Client-Oriented", ts'ebetso e matla ea taolo ea boleng bo holimo, lihlahisoa tse holimo tsa tlhahiso hammoho le sehlopha se matla sa R&D, re lula re fana ka lihlahisoa tsa boleng bo holimo, litharollo tse ikhethang le litšenyehelo tse matla bakeng sa Theko e Ntle bakeng sa Refractory Reaction Bonded Silicon Carbide Ceramic Beam Ka hona, bakeng sa Rbsic Beams ho tsoa ho li-Batts tse fapaneng li khona ho kopana. bareki ba fapaneng. Hopola ho fumana sebaka sa rona sa marang-rang ho sheba lintlha tse ling tse ngata ho tsoa lihlahisoa tsa rona.

Molemo ka ho fetisisa Theko bakeng saCeramic Roller le Silicon Carbide Kiln Shelves, Lihlahisoa tsa rona li tsejoa ka ho pharaletseng ebile li tšeptjoa ke basebelisi 'me li ka kopana le litlhoko tse tsoelang pele tsa moruo le tsa sechaba. Re amohela bareki ba bacha le ba khale ba tsoang mekhoeng eohle ea bophelo ho ikopanya le rona bakeng sa likamano tsa nako e tlang tsa khoebo le ho fihlela katleho e tšoanang!