Sesefo sa Ceramic Foam

Tlhaloso ea Sehlahisoa

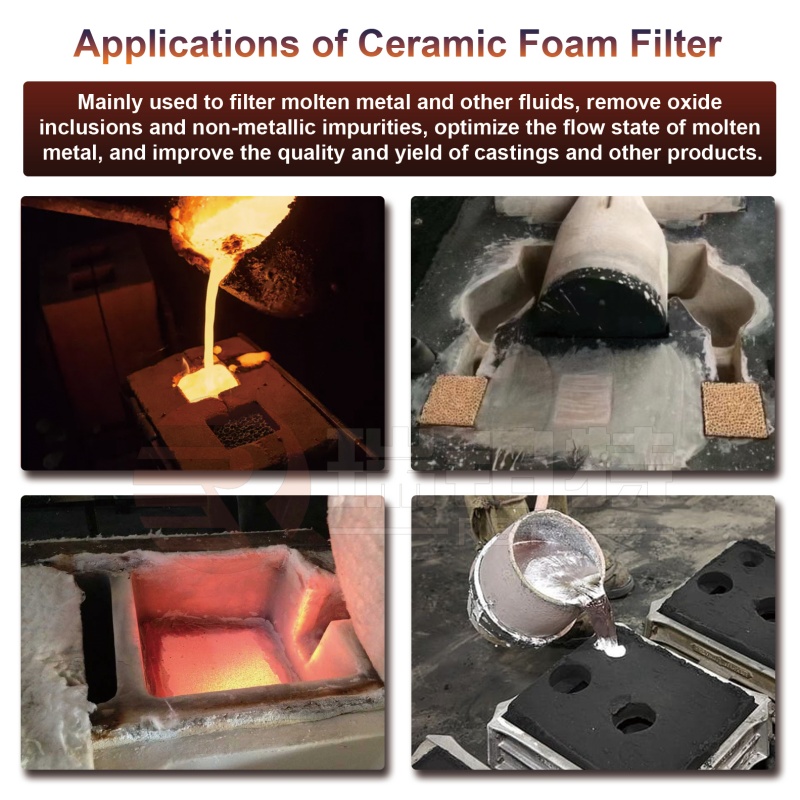

Sefahla sa letsopa sa ceramicke mofuta o mocha o sebedisoang ho sefa maro joalo ka tšepe e qhibidihileng. E na le sebopeho se ikhethileng le ts'ebetso e ntle haholo 'me e sebelisoa haholo liindastering tse kang ho lahla.

1. Alumina:

Mocheso o sebetsang: 1250 ℃. E loketse ho sefa le ho hloekisa tharollo ea aluminium le alloy. E sebelisoa haholo ho lahla lehlabathe le tloaelehileng le ho lahla hlobo e sa feleng joalo ka likarolo tsa likoloi tsa aluminium.

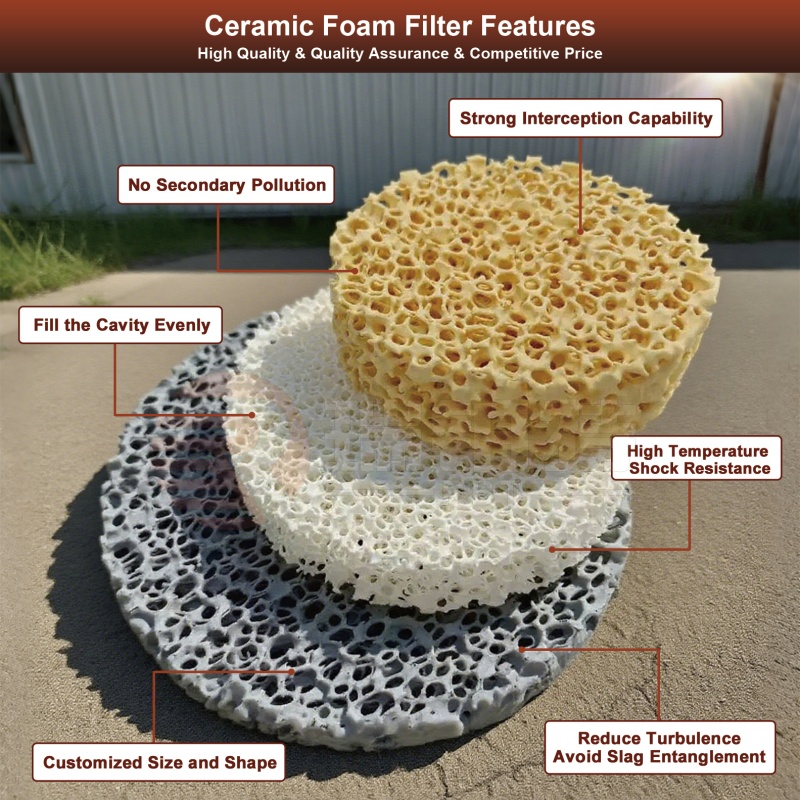

Melemo:

(1) Tlosa litšila ka katleho.

(2) Phallo ea aluminium e tsitsitseng e tsitsitseng ebile e bonolo ho e tlatsa.

(3) Fokotsa sekoli sa ho lahla, ntlafatsa boleng ba bokaholimo le thepa ea sehlahisoa.

2. SIC

E na le matla a babatsehang le ho hanyetsa mocheso o phahameng le ho bola ha lik'hemik'hale, 'me e khona ho mamella mocheso o ka bang 1560 ° C. E loketse ho lahla li-alloys tsa koporo le tšepe ea tšepe.

Melemo:

(1) Tlosa litšila 'me u ntlafatse bohloeki ba tšepe e qhibilihisitsoeng ka katleho.

(2) Fokotsa moferefere esita le ho tlatsa.

(3) Ntlafatsa boleng ba ho lahla le lihlahisoa, fokotsa kotsi ea sekoli.

3. Zirconia

Thempereichara e hanyetsanang le mocheso e phahame ho feta hoo e ka bang 1760 ℃, e na le matla a holimo le matla a ho hanyetsa mocheso o phahameng. E ka tlosa ka katleho litšila tse entsoeng ka tšepe le ho ntlafatsa boleng ba holim'a metsi le thepa ea mechine ea li-castings.

Melemo:

(1) Fokotsa litšila tse nyenyane.

(2) Fokotsa bofokoli ba holim'a metsi, ntlafatsa boleng bo holimo.

(3) Fokotsa ho sila, litšenyehelo tse tlase tsa mochini oa mochini.

4. Khokahano e thehiloeng ho carbon

E ntlafalitsoe ka ho khetheha bakeng sa lisebelisoa tsa tšepe tsa carbon le alloy low-alloy, filthara e entsoeng ka carbon-based ceramic foam e boetse e loketse litšepe tse kholo tsa tšepe. E tlosa ka katleho litšila tse ngata tse entsoeng ka tšepe e qhibilihisitsoeng ha e ntse e sebelisa sebaka sa eona se seholo sa holim'a metsi ho monya li-inclusions tse nyenyane haholo, ho etsa bonnete ba hore tšepe e qhibilihisitsoeng e tlatsoa ka boreleli. Sena se fella ka ho hloeka ha li-castings le ho fokotsoa

pherekano.

Melemo:

(1) Boima bo fokolang ba bongata, boima bo tlaase haholo le boima ba mocheso, bo bakang sebaka se tlaase haholo sa polokelo ea mocheso. Sena se thibela tšepe ea pele e qhibilihisitsoeng hore e se ke ea tiea ka har'a sefe le ho thusa hore tšepe e fete ka potlako ka sefeneng. Ho tlatsa filthara hang-hang ho thusa ho fokotsa moferefere o bakoang ke li-inclusions le slag.

(2) Mokhoa o sebelisoang haholo oa ts'ebetso, ho kenyelletsa lehlabathe, khetla, le lisebelisoa tse nepahetseng tsa ceramic.

(3) Mocheso o phahameng oa ho sebetsa oa 1650 ° C, o nolofatsa haholo mekhoa ea setso ea ho tšela.

(4) Sebopeho se khethehileng sa marang-rang se nang le mahlakore a mararo se laola ka mokhoa o nepahetseng phallo ea tšepe e ferekaneng, e bakang kabo e tšoanang ea microstructure ka ho lahla.

(5) E hloekisa ka katleho litšila tse nyane tse se nang tšepe, e ntlafatsa machinability ea likarolo.

(6) E ntlafatsa likarolo tse felletseng tsa mochini oa ho lahla, ho kenyelletsa le ho thatafala ha holim'a metsi, matla a tsitsipano, ho hanyetsa mokhathala le bolelele.

(7) Ha ho na tšusumetso e mpe ho remelting ea regrind e nang le lisebelisoa tsa filthara.

Index ea Lihlahisoa

| Mehlala le Parameters ea Alumina Ceramic Foam Filters | |||||

| Ntho | Compress Strength (MPa) | Porosity (%) | Boima ba Bongata (g/cm3) | Mocheso oa Mosebetsi (≤℃) | Lisebelisoa |

| RBT-01 | ≥0.8 | 80-90 | 0.35-0,55 | 1200 | Aluminium Alloy Casting |

| RBT-01B | ≥0.4 | 80-90 | 0.35-0,55 | 1200 | Mohaho o moholo oa Aluminium |

| Boholo le Bokhoni ba Alumina Ceramic Foam Filters | ||||

| Boholo(mm) | Boima(kg) | Sekhahla sa Phallo(kg/s) | Boima(kg) | Sekhahla sa Phallo(kg/s) |

| 10ppi | 20ppi | |||

| 50*50*22 | 42 | 2 | 30 | 1.5 |

| 75*75*22 | 96 | 5 | 67 | 4 |

| 100*100*22 | 170 | 9 | 120 | 7 |

| φ50*22 | 33 | 1.5 | 24 | 1.5 |

| φ75*22 | 75 | 4 | 53 | 3 |

| φ90*22 | 107 | 5 | 77 | 4.5 |

| Boholo bo boholo(Inch) | Boima (Ton) 20,30,40ppi | Sekhahla sa Phallo(kg/min) | ||

| 7"*7"*2" | 4.2 | 25-50 | ||

| 9"*9"*2" | 6 | 25-75 | ||

| 10"*10"*2" | 6.9 | 45-100 | ||

| 12"*12"*2" | 13.5 | 90-170 | ||

| 15"*15"*2" | 23.2 | 130-280 | ||

| 17"*17"*2" | 34.5 | 180-370 | ||

| 20"*20"*2" | 43.7 | 270-520 | ||

| 30"*23"*2" | 57.3 | 360-700 | ||

| Mehlala le Parameters ea SIC Ceramic Foam Filters | |||||

| Ntho | Compress Strength (MPa) | Porosity (%) | Boima ba Bongata (g/cm3) | Mocheso oa Mosebetsi (≤℃) | Lisebelisoa |

| RBT-0201 | ≥1.2 | ≥80 | 0.40-0,55 | 1480 | ductile iron, grey iron le non-ferro alloy |

| RBT-0202 | ≥1.5 | ≥80 | 0.35-0,60 | 1500 | Bakeng sa pouning e tobileng le li-castings tse kholo tsa tšepe |

| RBT-0203 | ≥1.8 | ≥80 | 0.47-0,55 | 1480 | Bakeng sa turbine ea moea le li-castings tse kholo |

| Boholo le Bokhoni ba SIC Ceramic Foam Filters | ||||||||

| Boholo(mm) | 10ppi | 20ppi | ||||||

| Boima(kg) | Sekhahla sa Phallo(kg/s) | Boima(kg) | Sekhahla sa Phallo(kg/s) | |||||

| Hlooho Tšepe | Tšepe ea Ductile | Tšepe e Bohlooho | Tšepe ea Ductile | Tšepe e Bohlooho | Tšepe ea Ductile | Tšepe e Bohlooho | Tšepe ea Ductile | |

| 40*40*15 | 40 | 22 | 3.1 | 2.3 | 35 | 18 | 2.9 | 2.2 |

| 40*40*22 | 64 | 32 | 4 | 3 | 50 | 25 | 3.2 | 2.5 |

| 50*30*22 | 60 | 30 | 4 | 3 | 48 | 24 | 3.5 | 2.5 |

| 50*50*15 | 50 | 30 | 3.5 | 2.6 | 45 | 26 | 3.2 | 2.5 |

| 50*50*22 | 100 | 50 | 6 | 4 | 80 | 40 | 5 | 3 |

| 75*50*22 | 150 | 75 | 9 | 6 | 120 | 60 | 7 | 5 |

| 75*75*22 | 220 | 110 | 14 | 9 | 176 | 88 | 11 | 7 |

| 100*50*22 | 200 | 100 | 12 | 8 | 160 | 80 | 10 | 6.5 |

| 100*100*22 | 400 | 200 | 24 | 15 | 320 | 160 | 19 | 12 |

| 150*150*22 | 900 | 450 | 50 | 36 | 720 | 360 | 40 | 30 |

| 150*150*40 | 850-1000 | 650-850 | 52-65 | 54-70 | _ | _ | _ | _ |

| 300*150*40 | 1200-1500 | 1000-1300 | 75-95 | 77-100 | _ | _ | _ | _ |

| φ50*22 | 80 | 40 | 5 | 4 | 64 | 32 | 4 | 3.2 |

| φ60*22 | 110 | 55 | 6 | 5 | 88 | 44 | 4.8 | 4 |

| φ75*22 | 176 | 88 | 11 | 7 | 140 | 70 | 8.8 | 5.6 |

| φ80*22 | 200 | 100 | 12 | 8 | 160 | 80 | 9.6 | 6.4 |

| φ90*22 | 240 | 120 | 16 | 10 | 190 | 96 | 9.6 | 8 |

| φ100*22 | 314 | 157 | 19 | 12 | 252 | 126 | 15.2 | 9.6 |

| φ125*25 | 400 | 220 | 28 | 18 | 320 | 176 | 22.4 | 14.4 |

| Mehlala le Parameters ea Zirconia Ceramic Foam Filters | |||||

| Ntho | Compress Strength (MPa) | Porosity (%) | Boima ba Bongata (g/cm3) | Mocheso oa Mosebetsi (≤℃) | Lisebelisoa |

| RBT-03 | ≥2.0 | ≥80 | 0.75-1.00 | 1700 | Bakeng sa tšepe e sa hloekang, tšepe ea Carbon le ho sefa ka boholo bo boholo ba tšepe ea tšepe |

| Boholo le Bokhoni ba Li-Filters tsa Ceramic Foam tsa Zirconia | |||

| Boholo(mm) | Sekhahla sa Phallo(kg/s) | Bokhoni(kg) | |

| Tšepe ea Carbon | Alloyed Steel | ||

| 50*50*22 | 2 | 3 | 55 |

| 50*50*25 | 2 | 3 | 55 |

| 55*55*25 | 4 | 5 | 75 |

| 60*60*22 | 3 | 4 | 80 |

| 60*60*25 | 4.5 | 5.5 | 86 |

| 66*66*22 | 3.5 | 5 | 97 |

| 75*75*25 | 4.5 | 7 | 120 |

| 100*100*25 | 8 | 10.5 | 220 |

| 125*125*30 | 18 | 20 | 375 |

| 150*150*30 | 18 | 23 | 490 |

| 200*200*35 | 48 | 53 | 960 |

| φ50*22 | 1.5 | 2.5 | 50 |

| φ50*25 | 1.5 | 2.5 | 50 |

| φ60*22 | 2 | 3.5 | 70 |

| φ60*25 | 2 | 3.5 | 70 |

| φ70*25 | 3 | 4.5 | 90 |

| φ75*25 | 3.5 | 5.5 | 110 |

| φ90*25 | 5 | 7.5 | 150 |

| φ100*25 | 6.5 | 9.5 | 180 |

| φ125*30 | 10 | 13 | 280 |

| φ150*30 | 13 | 17 | 400 |

| φ200*35 | 26 | 33 | 720 |

| Mehlala le Mekhahlelo ea Li-Filters tsa Bonding Ceramic Foam tse thehiloeng ho Carbon | |||||

| Ntho | Compress Strength (MPa) | Porosity (%) | Boima ba Bongata (g/cm3) | Mocheso oa Mosebetsi (≤℃) | Lisebelisoa |

| RBT-Carbon | ≥1.0 | ≥76 | 0.4-0.55 | 1650 | Tšepe ea carbon, tšepe e tlaase ea alloy, litšepe tse kholo tsa tšepe. |

| Boholo ba Lifilimi tsa Bonding Ceramic Foam tse thehiloeng ho Carbon | |

| 50*50*22 10/20ppi | φ50*22 10/20ppi |

| 55*55*25 10/20ppi | φ50*25 10/20ppi |

| 75*75*22 10/20ppi | φ60*25 10/20ppi |

| 75*75*25 10/20ppi | φ70*25 10/20ppi |

| 80*80*25 10/20ppi | φ75*25 10/20ppi |

| 90*90*25 10/20ppi | φ80*25 10/20ppi |

| 100*100*25 10/20ppi | φ90*25 10/20ppi |

| 125*125*30 10/20ppi | φ100*25 10/20ppi |

| 150*150*30 10/20ppi | φ125*30 10/20ppi |

| 175*175*30 10/20ppi | φ150*30 10/20ppi |

| 200*200*35 10/20ppi | φ200*35 10/20ppi |

| 250*250*35 10/20ppi | φ250*35 10/20ppi |

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e sebakeng sa Zibo City, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea lintho tse refractory. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea sebōpi, thekenoloji, le thepa ea ho rekisa kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a matla a tekheniki, boleng bo botle ba sehlahisoa le botumo bo botle. Feme ea rona e na le lihekthere tse fetang 200 mme tlhahiso ea selemo le selemo ea thepa e bōpehileng joaloka lithane tse ka bang 30000 'me thepa ea refractory e sa bopehang ke lithane tse 12000.

Lihlahisoa tsa rona tsa mantlha tsa thepa ea refractory li kenyelletsa:lisebelisoa tsa alkaline refractory; lisebelisoa tsa aluminium silicon refractory; thepa e sa bōpehang refractory; lisebelisoa tse thibelang mocheso oa mocheso; thepa e khethehileng refractory; lisebelisoa tse sebetsang tsa refractory bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Hangata

U hloka thuso? Etsa bonnete ba hore u etela liforomo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, feme ea rona e khethehile ho hlahisa thepa ea refractory ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ka mor'a ho rekisa.

Bakeng sa ts'ebetso e 'ngoe le e' ngoe ea tlhahiso, RBT e na le tsamaiso e feletseng ea QC bakeng sa metsoako ea lik'hemik'hale le thepa ea 'mele. 'Me re tla hlahloba thepa,' me setifikeiti sa boleng se tla romelloa ka thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho itšetlehile ka bongata, nako ea rona ea ho fana e fapane. Empa re tšepisa ho romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ha e le hantle, re fana ka mehlala ea mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e molemohali ho latela boemo ba hau.

Re 'nile ra etsa thepa ea refractory ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le phihlelo e ruileng, re ka thusa bareki ho rala li-kilns tse fapaneng le ho fana ka ts'ebeletso e le 'ngoe.