Sagger ea letsopa

Tlhahisoleseding ea Sehlahisoa

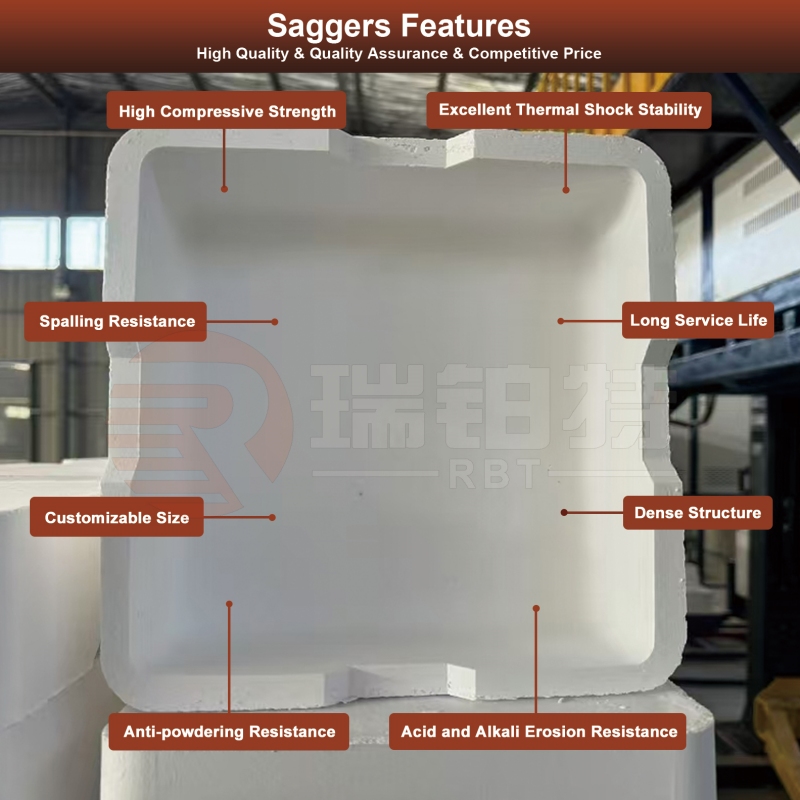

Li-saggerHangata li entsoe ka thepa e hanyetsang, haholo-holo ho kenyeletsoa mullite, corundum, alumina, cordierite, le silicon carbide. Sebopeho sa tsona se ikgethang se fapana ho latela tshebediso ya tsona e rerilweng. Mosebetsi wa tsona wa mantlha ke ho sireletsa dintho ho tloha ho qhibiliheng ha mocheso o phahameng le ho netefatsa ho thunya ka ho tshwana.

Lisebelisoa tse tloaelehileng:

Tse ngata:Jwalo ka thepa ya matrix, e fana ka thepa e phahameng ya ho hanyetsa mme e sebediswa haholo diindastering tsa saggers.

Corundum:E tiile haholo ebile e hanela mafome, e loketse libaka tse nang le mocheso o phahameng.

Alumina:Ho hanyetsa mocheso o phahameng haholo, ho sebelisoang haholo liindastering tsa saggers.

Cordierite:E ntlafatsa khanyetso ea mocheso ea thepa.

Carbide ea silicon:E ntlafatsa ho hanyetsa ho bola ha lera la aggregate.

Mokokotlo oa Magnesium-aluminium:E ntlafatsa matla a mechini a lera la matrix.

(Mona re hlahisa haholo-holo mullite, corundum, alumina, cordierite, jj. tseo re atisang ho li fana.)

Mosebetsi oa mantlha:

Ho behwa ka thoko:E sireletsa lintho hore li se ke tsa kopana ka ho toba le litšila tse kang lerōle le litšila tse ka ontong, kahoo e thibela tšilafalo.

Ho futhumatsa ka mokhoa o ts'oanang:E fokotsa kotsi ea ho fetoha kapa ho petsoha ho bakoang ke mocheso o phahameng oa sebakeng seo, e ntlafatsa chai.

Nako e telele ea bophelo:Ka ho ntlafatsa karolelano ea thepa (joalo ka ho eketsa silicon carbide le magnesia-alumina spinel), khanyetso ea sagger ea mafome libakeng tsa letsoai le qhibilihisitsoeng tse nang le mocheso o phahameng e ka ntlafala haholo, ea eketsa nako ea ts'ebeletso ea eona.

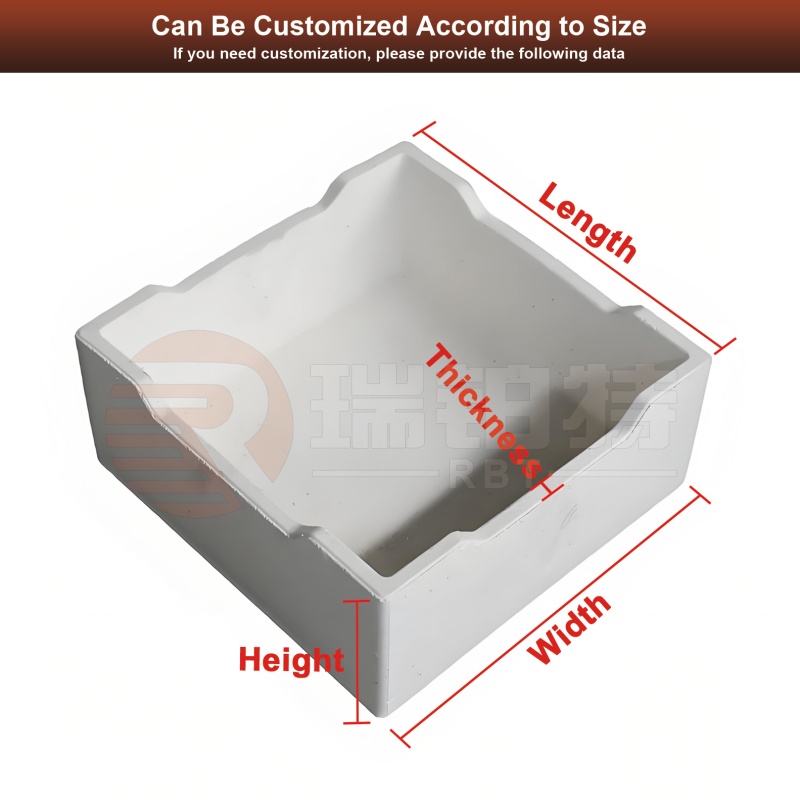

Sebopeho sa sagger se itshetlehile haholo-holo hodima tshebediso le ditlhoko tsa sehlahiswa. Re fana ka dibopeho tse latelang tse ka sehloohong:

Sekwere

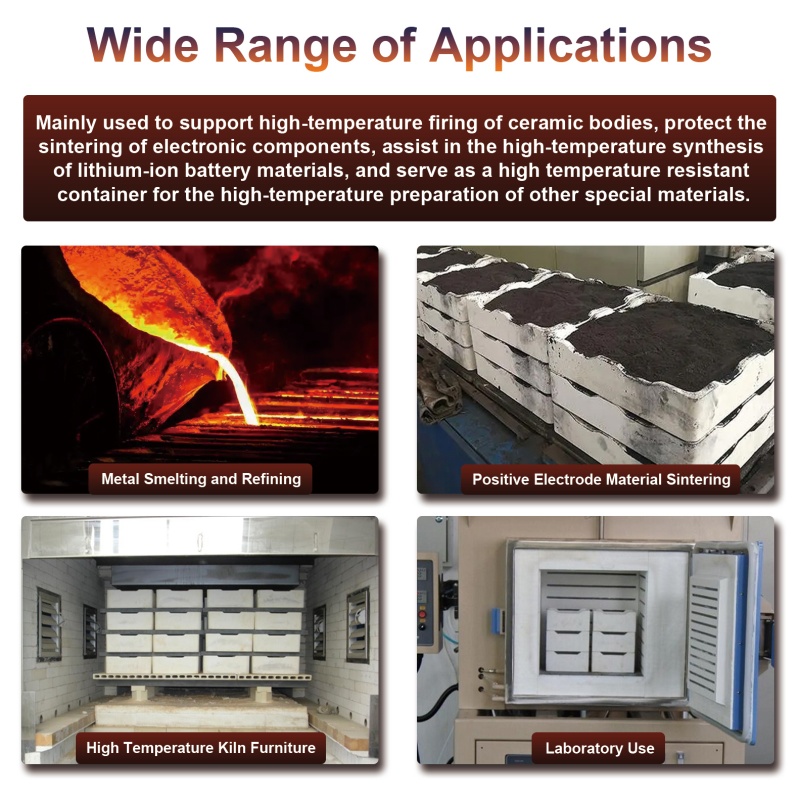

Li-sagger li sebelisoa hangata lilaboratoring le tlhahisong ea indasteri, li loketse ho sintering le ho qhibilihisa mocheso o phahameng.

Selika-likoe

Hangata li-sagger li sebelisoa lits'ebetsong tsa ho sebetsa ka mokhoa o nepahetseng joalo ka likarolo tsa elektroniki le likarolo tsa sebopeho tse nang le mocheso o phahameng, li fana ka litšobotsi tse ntle tsa ho futhumatsa tse tšoanang.

Libopeho tse Ikhethang

Li-sagges li ka etsoa hore li lumellane le litlhoko tsa bareki ka libopeho tse fapaneng, ho kenyeletsoa le tse kobehileng, tse khutlonnetsepa le tse cylindrical. Tsena li sebelisoa hangata lits'ebetsong tse ikhethileng tse kang

ho besa ka letsopa le ho kenya phofo.

Lethathamo la Sehlahisoa

| Ntho | Cordierite | Corundum | Corundum-cordierite | Corundum-mullite |

| Al2O3 (%) | ≥ 32 | ≥ 68 | ≥ 57 | ≥ 80 |

| Fe2O3 % | ≤ 1.5 | ≤ 1.2 | ≤ 1.5 | ≤ 1.2 |

| Boima ba g/cm3 | 2.0 | 2.4 | 2.2 | 2.7 |

| Katoloso ea Thermal-1000 | 0.15 | 0.30 | 0.27 | 0.33 |

| Mocheso o sa thekeseleng (℃) | ≥ 1460 | ≥ 1750 | ≥ 1700 | ≥ 1800 |

| Katoloso ea Thermal (1100℃ ho pholisa metsi) Linako | ≥ 70 | ≥ 50 | ≥ 60 | ≥ 40 |

| Mocheso oa Kopo (℃) | ≤ 1250 | ≤ 1350 | ≤ 1300 | ≤ 1400 |

Li-sagger tse ngata

Haholo-holo li sebelisoa bakeng sa ho sintering mochesong o phahameng lits'ebetsong tse kang thepa ea cathode ea betri ea lithium, li-oxide tsa rare earth, le electrolysis ea aluminium, li fana ka khanyetso mochesong o phahameng, khanyetso ea mafome, le botsitso bo botle ba ho thothomela ha mocheso. Li ka sebelisoa mochesong o pakeng tsa 1300-1600°C.

Li-cordierite saggers

E loketse li-ceramic tsa ntlo tse silang, li-ceramic tsa meralo, le li-ceramic tsa elektroniki. Li na le coefficient e tlase ea katoloso ea mocheso le ho phatloha ho hoholo ha mocheso.botsitso. Mocheso oa tsona oa ts'ebetso ea nako e telele o pakeng tsa 1000-1300°C.

Li-sagger tsa Corundum

Li sebelisoa bakeng sa ho sila liseramike tse khethehileng, likarolo tsa elektroniki le thepa ea makenete, li fana ka khanyetso e ntle ea mocheso o phahameng (1600-1750°C), khanyetso ea mafome, le botsitso bo botle ba ho thothomela ha mocheso.

Li-sagger tsa Alumina

Li sebelisoa hangata ho beseng li-ceramic tse tloaelehileng, li fana ka matla a phahameng le ho hanyetsa ho ts'oaroa ke mocheso, 'me li ka sebelisoa mochesong o kaholimo ho 1300°C.

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e fumaneha Motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa e hanyetsang. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea ontong, theknoloji le thepa e hanyetsang kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a tekheniki a matla, boleng bo botle ba sehlahisoa, le botumo bo botle. Feme ea rona e akaretsa lihekthere tse fetang 200 'me tlhahiso ea selemo le selemo ea thepa e hanyetsang e bōpehileng joaloka e ka ba lithane tse 30000 'me thepa e hanyetsang e sa bōpehang joaloka e hanyetsang ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa e hanyetsang li kenyelletsa:thepa e hanyetsang alkaline; thepa e hanyetsang silicon ea aluminium; thepa e sa bōpehang e hanyetsang; thepa e thibelang mocheso e thibelang mocheso; thepa e khethehileng e thibelang; thepa e sebetsang e thibelang bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Khafetsa

Na u hloka thuso? Etsa bonnete ba hore u etela liforamo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, fektheri ea rona e ikhethile ka ho hlahisa thepa e hanyetsang ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ea kamora thekiso.

Bakeng sa ts'ebetso e 'ngoe le e 'ngoe ea tlhahiso, RBT e na le sistimi e felletseng ea QC bakeng sa sebopeho sa lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa, 'me setifikeiti sa boleng se tla romelloa le thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho latela bongata, nako ea rona ea ho tlisa thepa e fapane. Empa re tšepisa ho e romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ehlile, re fana ka disampole tsa mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e ntle ka ho fetisisa ho latela boemo ba hau.

Re ntse re etsa thepa e hanyetsang mocheso ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le boiphihlelo bo bongata, re ka thusa bareki ho rala li-kiln tse fapaneng le ho fana ka tšebeletso ea ho emisa hang feela.