High Alumina Refractory Castable

Tlhahisoleseding ya Sehlahiswa

| Lebitso la Sehlahiswa | Refractory Castable |

| Lihlopha | Low Cement Castable/High Strength Castable/High Alumina Castable / Lightweight Castable |

| Sebopeho | Refractory aggregates, powders le binders |

| Likaroloana | 1.Kaho e Bonolo, 2.Ho hanyetsa Slag e ntle, 3.Ho hanyetsa Corrosion e ntle, 4.Ho hanyetsa mollo o motle, 5.Ho Boloka Matla le Tšireletso ea Tikoloho. |

| Lisebelisoa | E Sebelisoa Haholo Litšeng Tse sa Tšoaneng Tsa Mocheso o Phahameng oa Liindasteri. |

| Lihlahisoa | Low Cement Castable | Matla a Phahameng a Lahla |

| Tlhaloso | Li-castable tsa samente tse tlase li bua ka liphahlo tse ncha tse nang le sekontiri se senyenyane sa samente.Likahare tsa samente tsa li-castable tse refractory hangata ke 15% ho isa ho 20%, 'me likahare tsa samente tsa samente tse tlase li ka ba 5%,' me tse ling li bile li fokotsehile ho 1% ho isa ho 2%. | Matla a phahameng a sa senyeheng a entsoe ka kakaretso ea matla a holimo, metsoako ea liminerale, aggregate ea matla a phahameng le anti crack le agent e hananang le ho apara. |

| Likaroloana | Ho hanyetsa mocheso oa mocheso, ho hanyetsa slag, le khanyetso ea khoholeho e ntlafala haholo, ho feta litene tse tšoanang tse refractory. | Matla a phahameng, ho hanyetsa ho apara ho phahameng, ho hanyetsa tšusumetso, ho hanyetsa khoholeho, ho thibela oli ho kenella, ho laola sebopeho ka mokhoa o ikemetseng, botšepehi bo matla, kaho e bonolo, ts'ebetso e ntle ea kaho, le tšebeletso e telele. |

| Lisebelisoa | 1.Lining tsa libōpi tse fapa-fapaneng tsa mocheso oa mocheso, libōpi tse futhumatsang, li-shaft kilns, li-rotary kilns, likoahelo tsa sebōpi sa motlakase, li-tapholes tsa sebōpi se phatlohang; 2. Li-castable tse nang le samente e tlaase li loketse mocheso o phahameng oa mocheso oa lithunya tsa spray bakeng sa metallurgy ea spray le petrochemical catalytic cracking reactors Lesela le sa keneleng ho apara, lesela le ka ntle la sebōpi se futhumatsang metsi a pholileng pipe, joalo-joalo. | Lera le manganga la slag sluice,sejaneng sa mashala, sekoti sa mashala, hopper le silo ka metallurgy, mashala, matla a mocheso, lik'hemik'hale,samente le liindasteri tse ling, le sebōpi se chesang ho kopanya silo, silo ea sintering, feeder, pelletizer, joalo-joalo. |

| Lihlahisoa | High Alumina Castable | Khanya e bobebe |

| Tlhaloso | Li-castable tsa aluminium tse phahameng lia hanyetsali-castable tse entsoeng ka thepa e tala ea aluminium e phahamenge le li-aggregates le li-powders, 'me li ekeletsoae nang le ba tlamang. | Thepa e bobebe e nang le boima bo tlase ba bongata bo entsoe ka samente ea aluminate, thepa e ntle ea alumina e phahameng, ceramsite le li-additives. |

| Likaroloana | E na le matla a phahameng a mochine le ho hanyetsa mocheso o motle oa mocheso, ho hanyetsa abrasion le lisebelisoa tse ling. | Bongata bo tlase ba bongata, conductivity e nyane ea mocheso, phello e ntle ea ho kenya mocheso, matla a phahameng a khatello, acid le acid e hanyetsanang le kutu ea khase, ho kenya mocheso, ho kenya mocheso, le ho monya metsi a tlase. |

| Lisebelisoa | E sebelisoa haholo-holo e le lesela le ka hare la li-boilers, setofo se chesang sebōpi se chesang, libōpi tsa ho futhumatsa, libōpi tsa ceramic le liotlolo tse ling. | The lightweight castable e ka sebelisoa bakeng sa lera la ho kenya mocheso oa sebōpi sa liindasteri tse nang le mocheso o phahameng oa mocheso le lisebelisoa tse sebelisoang hape bakeng sa lesela la liphaephe tse fapaneng tsa mocheso o phahameng oa mocheso. |

Index ea Lihlahisoa

Hot Blast Stove

Sebōpi sa Tunnel

Rotary Kiln

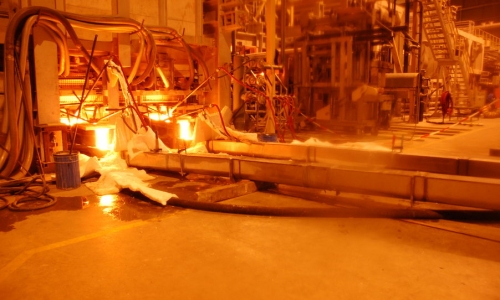

Indasteri ea tšepe le tšepe: haholo-holo e sebelisetsoang ho lokisa le ho pata libono tsa motlakase tsa arc, libopi tsa tšepe, lilae le lisebelisoa tse ling.

Indasteri ea tšepe e se nang ferrous: e sebelisetsoang ho lokisoa le ho lokisa koporo, aluminium, zinki, nickel le libopi tse ling tse se nang ferrous tse qhibilihisang tšepe le li-converter.

Indasteri ea likhalase: e sebelisetsoa ho lokisa le ho lokisa libono tsa likhalase, libopi tsa likhalase le lisebelisoa tse ling.

| Lebitso la Sehlahiswa | Low Cement Castable | |||||

| INDEX | RBTZJ-42 | RBTZJ-60 | RBTZJ-65 | RBTZJS-65 | RBTZJ-70 | |

| Mokhahlelo oa Moeli oa Mosebetsi | 1300 | 1350 | 1400 | 1400 | 1450 | |

| Boima ba Bongata(g/cm3)110℃×24h ≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Matla a Kobehang a Cold110℃×24h(MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Cold Crushing Strength(MPa) ≥ | 110℃×24h | 25 | 30 | 35 | 35 | 40 |

| CT℃×3h | 50 1300℃×3h | 55 1350 ℃×3h | 60 1400℃×3h | 40 1400℃×3h | 70 1400℃×3h | |

| Phetoho ea Linear e sa Feleng@CT℃×3h(%) | -0.5~+0,5 1300 ℃ | -0.5~+0,5 1350 ℃ | 0~+0.8 1400 ℃ | 0~+0.8 1400 ℃ | 0~+1.0 1400 ℃ | |

| Thermal Shock Resistance1000 ℃ metsi) ≥ | ― | ― | ― | 20 | ― | |

| Al2O3(%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| CaO(%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| Fe2O3(%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Lebitso la Sehlahiswa | Matla a Phahameng a Lahla | |||||

| INDEX | HS-50 | HS-60 | HS-70 | HS-80 | HS-90 | |

| Mocheso o lekanyelitsoeng oa ho sebetsa(℃) | 1400 | 1500 | 1600 | 1700 | 1800 | |

| 110℃ Boima ba Bongata (g/cm3) ≥ | 2.15 | 2.30 | 2.40 | 2.50 | 2.90 | |

| Modulus of Rupture (MPa) ≥ | 110℃×24h | 6 | 8 | 8 | 8.5 | 10 |

| 1100℃×3h | 8 | 8.5 | 8.5 | 9 | 9.5 | |

| 1400℃×3h | 8.5 1300℃×3h | 9 | 9.5 | 10 | 15 | |

| Cold Crushing Strength(MPa) ≥ | 110℃×24h | 35 | 40 | 40 | 45 | 60 |

| 1100℃×3h | 40 | 50 | 45 | 50 | 70 | |

| 1400℃×3h | 45 1300℃×3h | 55 | 50 | 55 | 100 | |

| Phetoho e sa Feleng ea Linear(%) | 1100℃×3h | -0.2 | -0.2 | -0.25 | -0.15 | -0.1 |

| 1400℃×3h | -0,45 1300℃×3h | -0.4 | -0.3 | -0.3 | -0.1 | |

| Al2O3(%) ≥ | 48 | 48 | 55 | 65 | 75 | 90 |

| CaO(%) ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Fe2O3(%) ≤ | 3.5 | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 |

| Lebitso la Sehlahiswa | High Alumina Castable | ||||||

| INDEX | Al2O3(%)≥ | CaO(%)≥ | Refractoriness(℃) | CT℃×3h PLC ≤1% | 110℃Kamora ho Omisa (MPa) | ||

| CCS | MOTS'EOA | ||||||

| Clay Bonded | NL-45 | 45 | ― | 1700 | 1350 | 8 | 1 |

| NL-60 | 60 | ― | 1720 | 1400 | 9 | 1.5 | |

| NL-70 | 70 | ― | 1760 | 1450 | 10 | 2 | |

| Samente e Kopantsoeng | GL-42 | 42 | ― | 1640 | 1350 | 25 | 3.5 |

| GL-50 | 50 | ― | 1660 | 1400 | 30 | 4 | |

| GL-60 | 60 | ― | 1700 | 1400 | 30 | 4 | |

| GL-70 | 70 | ― | 1720 | 1450 | 35 | 5 | |

| GL-85 | 85 | ― | 1780 | 1500 | 35 | 5 | |

| Samente e Tlase e Tlantsoeng | DL-60 | 60 | 2.5 | 1740 | 1500 | 30 | 5 |

| DL-80 | 80 | 2.5 | 1780 | 1500 | 40 | 6 | |

| Phosphate Bonded | LL-45 | 45 | ― | 1700 | 1350 | 20 | 3.5 |

| LL-60 | 60 | ― | 1740 | 1450 | 25 | 4 | |

| LL-75 | 75 | ― | 1780 | 1500 | 30 | 5 | |

| Sodium silicate e kopantsoeng | BL-40 | 40 | ― | ― | 1000 | 20 | ― |

| Lebitso la Sehlahiswa | Khanya e bobebe | ||||||

| Mocheso o lekanyelitsoeng oa ho sebetsa | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110℃ Boima ba Bongata (g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Modulus of Rupture (MPa) ≥ | 110℃×24h | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100℃×3h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400℃×3h | ― | ― | 3 | 10.8 | 8.1 | ||

| Cold Crushing Power(MPa) ≥ | 110℃×24h | 8 | 8 | 11 | 12 | 10 | |

| 1100℃×3h | 4 | 4 | 5 | 11 | 10 | ||

| 1400℃×3h | ― | ― | 15 | 22 | 14 | ||

| Phetoho e sa Feleng ea Linear(%) | 1100℃×3h | -0,65 1000℃×3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400℃×3h | ― | ― | -0.8 | -0.55 | -0.45 | ||

| Thermal Conductivity (W/mk) | 350 ℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700 ℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| Al2O3(%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

Kopo

Sephutheloana le Bobolokelo