Litene tsa Corundum/Litene tsa Corundum Mullite

Tlhahisoleseding ea Sehlahisoa

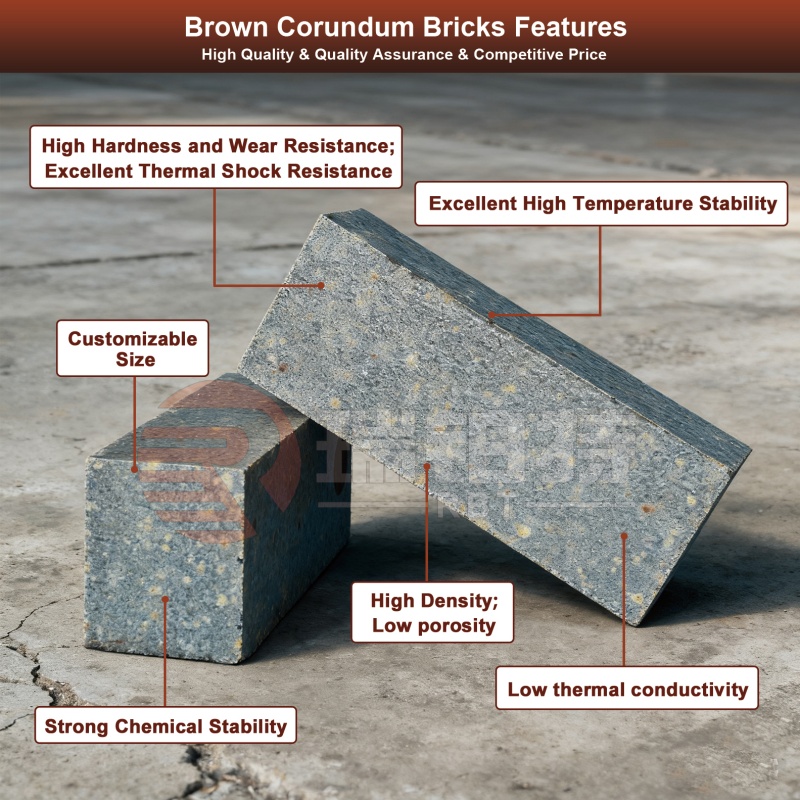

Setene sa Corundumke dihlahiswa tse hanyetsang tse nang le corundum e le karolo ya mantlha ya kristale, mme dikahare tsa alumina di feta 90%.

Tlhophiso:Litene tsa Corundum li arotsoe haholo-holo ka litene tsa corundum tse sintered le litene tsa corundum tse fused. Ea pele e entsoe ka alumina e sintered, ha ea morao e entsoe ka corundum e fused. Litene tsa corundum tse sa besoang li ka boela tsa etsoa ka ho sebelisa phosphoric acid kapa li-binder tse ling.

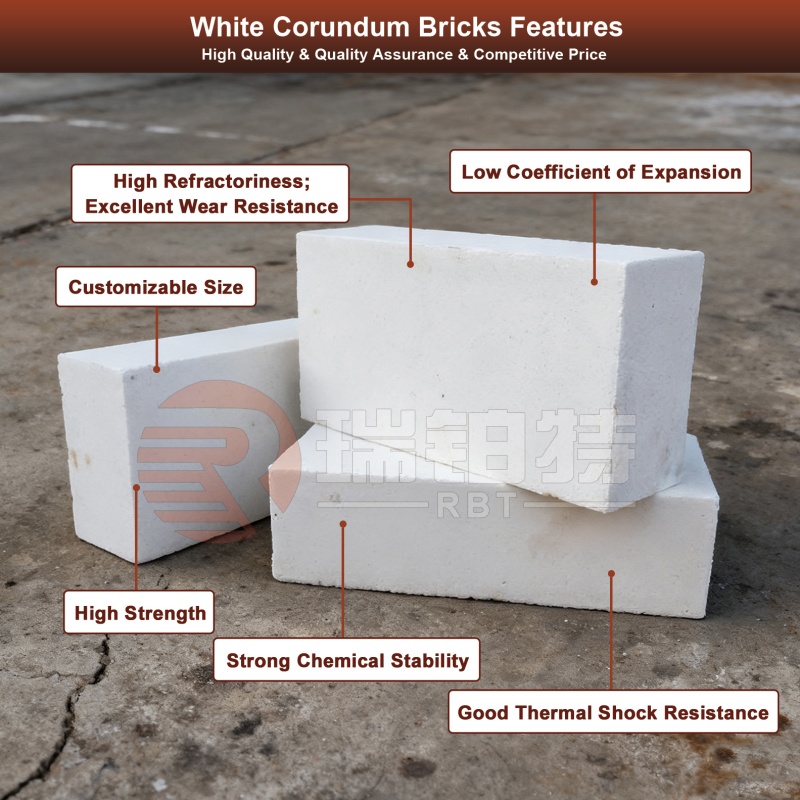

Litšobotsi tsa Tshebetso:

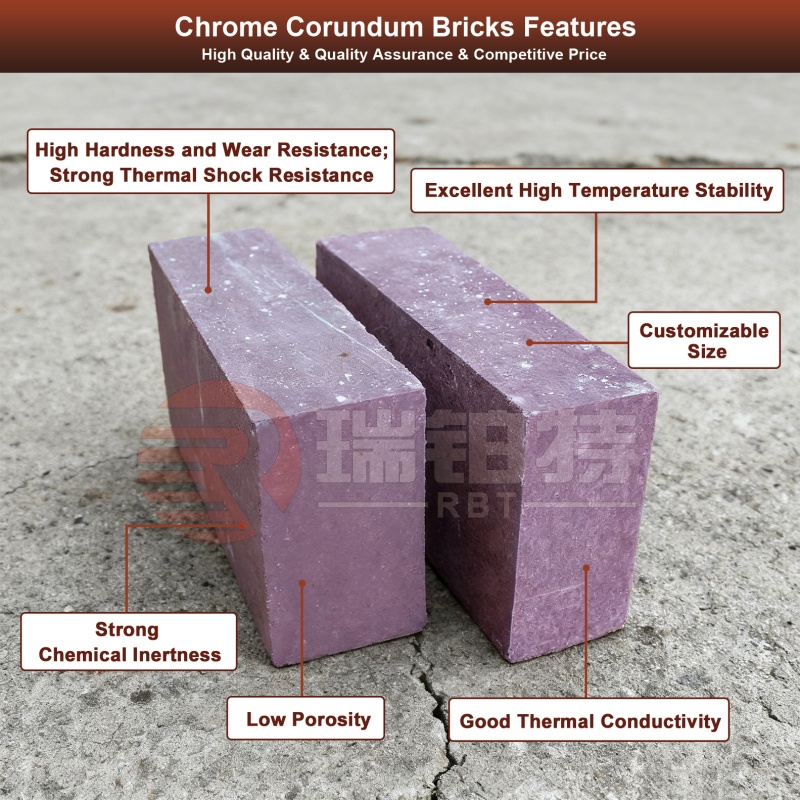

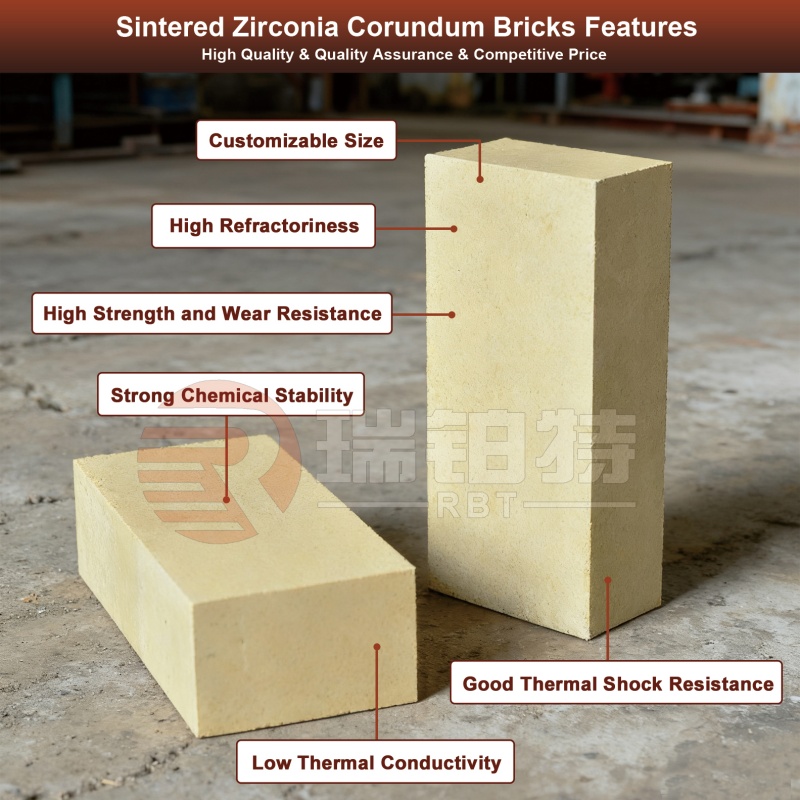

Matlotlo a Matle a Refractory:Mocheso o nolofatsang le o sa jarisoang oa litene tsa corundum o feta 1700°C, 'me litene tse ling tsa chrome corundum li ka fihla mochesong o fetang 1790°C. Li lula li tsitsitse libakeng tse nang le mocheso o phahameng 'me ha li kotsing ea ho fetoha kapa ho senyeha.

Matla a Phahameng:Matla a ho hatella a litene tsa corundum tse hloekileng haholo mochesong oa kamore hangata ke 70MPa-100MPa, ha a litene tsa chrome corundum tse sebetsang hantle a feta 150MPa 'me a ka fihla ho 340MPa.

Botsitso bo Botle ba Lik'hemik'hale:Litene tsa Corundum li hanela haholo mafome a asiti kapa a alkaline, litšepe le khalase e qhibilihisitsoeng, 'me ha li angoe ke lik'hemik'hale.

Ho hanyetsa khoholeho ea slag ka matla:Mohlala, dikahare tsa Cr₂O₃ tse ka hara ditena tsa chrome corundum di thibela ka katleho slag e qhibilihisitsweng ho kena mmeleng wa ditena ka hara masoba a capillary, e leng se fellang ka ho hanyetsa kgoholeho e phahameng ya slag ho ditena tse tlwaelehileng tsa corundum.

Lisebelisoa tse ka Sehloohong le Lisebelisoa tse Tala:

Karolo ea mantlha ea litene tsa corundum ke alumina (Al₂O₃), eo hangata e fetang 90%, 'me tse ling li na le ho fihlela ho 99%. Lisebelisoa tse tala li kenyelletsa alumina e sintered le corundum e kopantsoeng. Lisebelisoa tse ling tsa diminerale le tsona li ka eketsoa ho etsa lisebelisoa tse kopaneng, tse kang Cr₂O₃ bakeng sa litene tsa chrome corundum le ZrO₂ bakeng sa litene tsa zirconium corundum.

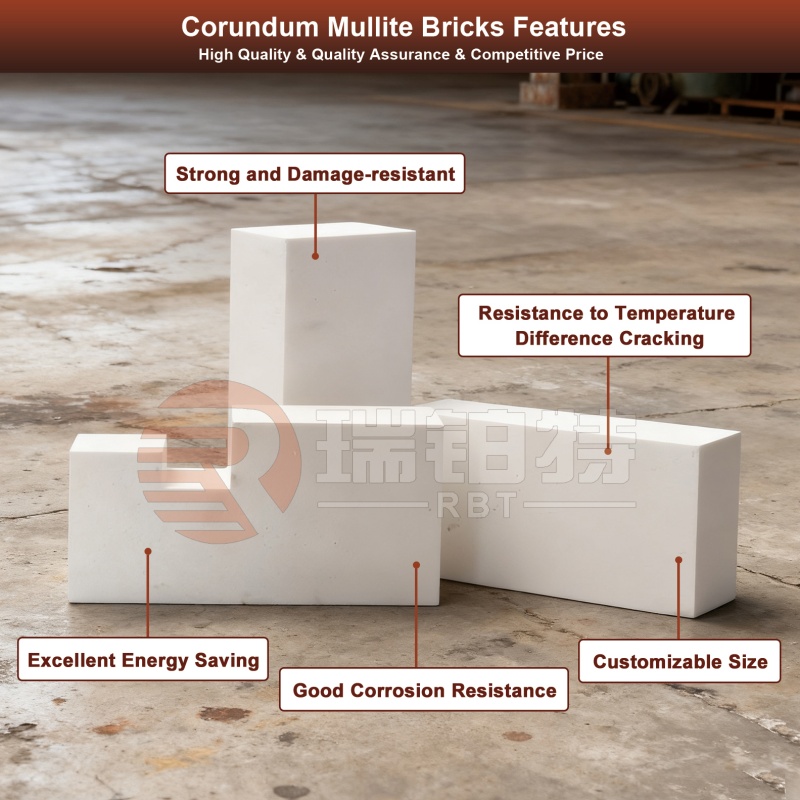

Litene tsa Corundum-mulliteke litene tse kopantsoeng tse hanyetsang tse entsoeng ka mekhahlelo e 'meli e tsitsitseng ea mocheso o phahameng: corundum (Al₂O₃) le mullite (3Al₂O₃・2SiO₂). Li kopanya matla a phahameng a corundum le khanyetso e ntle ea mocheso ea mullite, e leng se etsang hore e be thepa ea mocheso o phahameng e leka-lekaneng ts'ebetso le katleho ea litšenyehelo.

Likarolo tsa Motheo le Likarolo tsa Sebopeho

Sebopeho sa Karolo e ka Sehloohong ea Crystalline:Corundum le mullite ke mekhahlelo e 'meli e meholo ea kristale, ka bongata ba alumina hangata bo tloha ho 70% ho isa ho 90%, 'me karolo e setseng haholo-holo silicon dioxide (SiO₂). Tšusumetso ea tšebelisano-'moho ea mekhahlelo ena e 'meli e leka-lekanya ts'ebetso.

Sebopeho se senyenyane:Mekhahlelo ea mullite e ajoa pakeng tsa lithollo tsa corundum ka mokhoa oa likristale tse bōpehileng joaloka nale kapa columnar, tse etsang sebopeho sa "corundum skeleton + mullite connection". Sena ha se ntlafatse matla a setene feela empa se boetse se thibela khatello ea mocheso ka likheo tsa micro-crystal.

Melemo ea Bohlokoa ea Tshebetso

Khanyetso e ikhethang ea ho ts'oaroa ke mocheso:Ena ke molemo oa eona oa mantlha. Mullite e na le coefficient e tlase ea katoloso ea mocheso, 'me sebopeho sa eona sa kristale se bōpehileng joaloka nale se monya khatello e bakoang ke ho feto-fetoha ha mocheso, se fokotsa haholo ho petsoha ho bakoang ke ho phola le ho futhumatsa ka potlako mochesong o phahameng. Tshebetso ea eona e feta ea litene tse hloekileng tsa corundum.

Matla a leka-lekaneng le ho hanyetsa mafome:Boteng ba karolo ea corundum bo netefatsa matla a phahameng mochesong oa kamore le mochesong o phahameng, ha ka nako e ts'oanang bo fana ka khanyetso e ntle khahlanong le slag ea asiti, khalase e qhibilihisitsoeng le mecha e meng ea phatlalatso. Leha khanyetso ea eona ea alkali e le tlase hanyane ho feta ea litene tsa chrome corundum, e fana ka mefuta e mengata ea lits'ebetso.

Ho tsamaisa mocheso ka tekanyo e itekanetseng:Ha e bapisoa le litene tsa corundum tse nang le bongata bo phahameng, e fana ka phallo e tlase ea mocheso ha e ntse e boloka tekanyo e itseng ea ho thibela mocheso, e fokotsa tahlehelo ea mocheso lisebelisoa tsa mocheso o phahameng le ho e etsa hore e lokele lits'ebetso tse hlokang ho thibela mocheso.

Lethathamo la Sehlahisoa

| Litene tsa Corundum | ||||

| INDEX | GYZ-99A | GYZ-99B | GYZ-98 | GYZ-95 |

| Al2O3 (%)≥ | 99 | 99 | 98 | 95 |

| SiO2 (%)≤ | 0.15 | 0.2 | 0.5 | --- |

| Fe2O3 (%)≤ | 0.10 | 0.15 | 0.2 | 0.3 |

| Ho bonahala ho na le masoba (%)≤ | 19 | 19 | 19 | 20 |

| Bongata ba Bongata (g/cm3) ≥ | 3.20 | 3.15 | 3.15 | 3.1 |

| Matla a ho Silakanya a Batang (MPa) ≥ | 80 | 80 | 80 | 100 |

| Phetoho e sa Feleng ea Linear (1600°×3h) /% | -0.2~+0.2 | -0.2~+0.2 | -0.2~+0.2 | -0.3~+0.3 |

| Ho se be le kganya tlasa mojaro (0.2MPa, 0.6%)/℃ ≤ | 1700 | 1700 | 1700 | 1700 |

| Litene tsa Corundum-mullite | ||||

| INDEX | GMZ-88 | GMZ-85 | GMZ-80 | GYZ-75 |

| Al2O3 (%)≥ | 88 | 85 | 80 | 75 |

| Fe2O3 (%)≤ | 0.8 | 1.0 | 1.0 | 1.2 |

| Ho bonahala ho na le masoba (%)≤ | 15(17) | 16(18) | 18(20) | 18(20) |

| Bongata ba Bongata (g/cm3) ≥ | 3.00 | 2.85 | 2.75 | 2.60 |

| Matla a ho Silakanya a Batang (MPa) | 100-120 | 80-100 | 80-100 | 60-80 |

| Phetoho e sa Feleng ea Linear (1600°×3h) /% | -0.1~+0.1 | -0.1~+0.1 | -0.2~+0.2 | -0.2~+0.2 |

| Ho se be le kganya tlasa mojaro (0.2MPa, 0.6%)/℃ ≤ | 1700 | 1680 | 1650 | 1650 |

Kopo

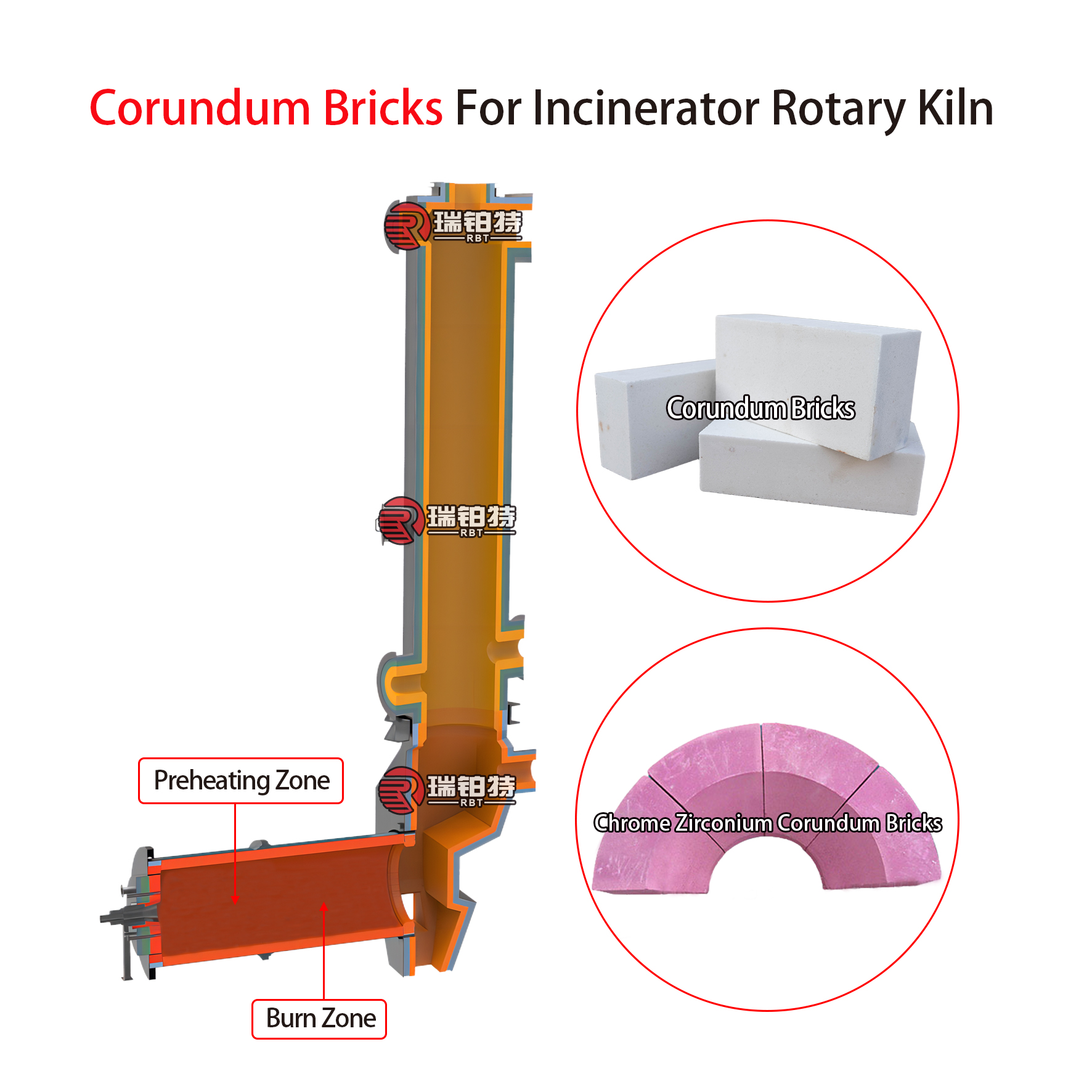

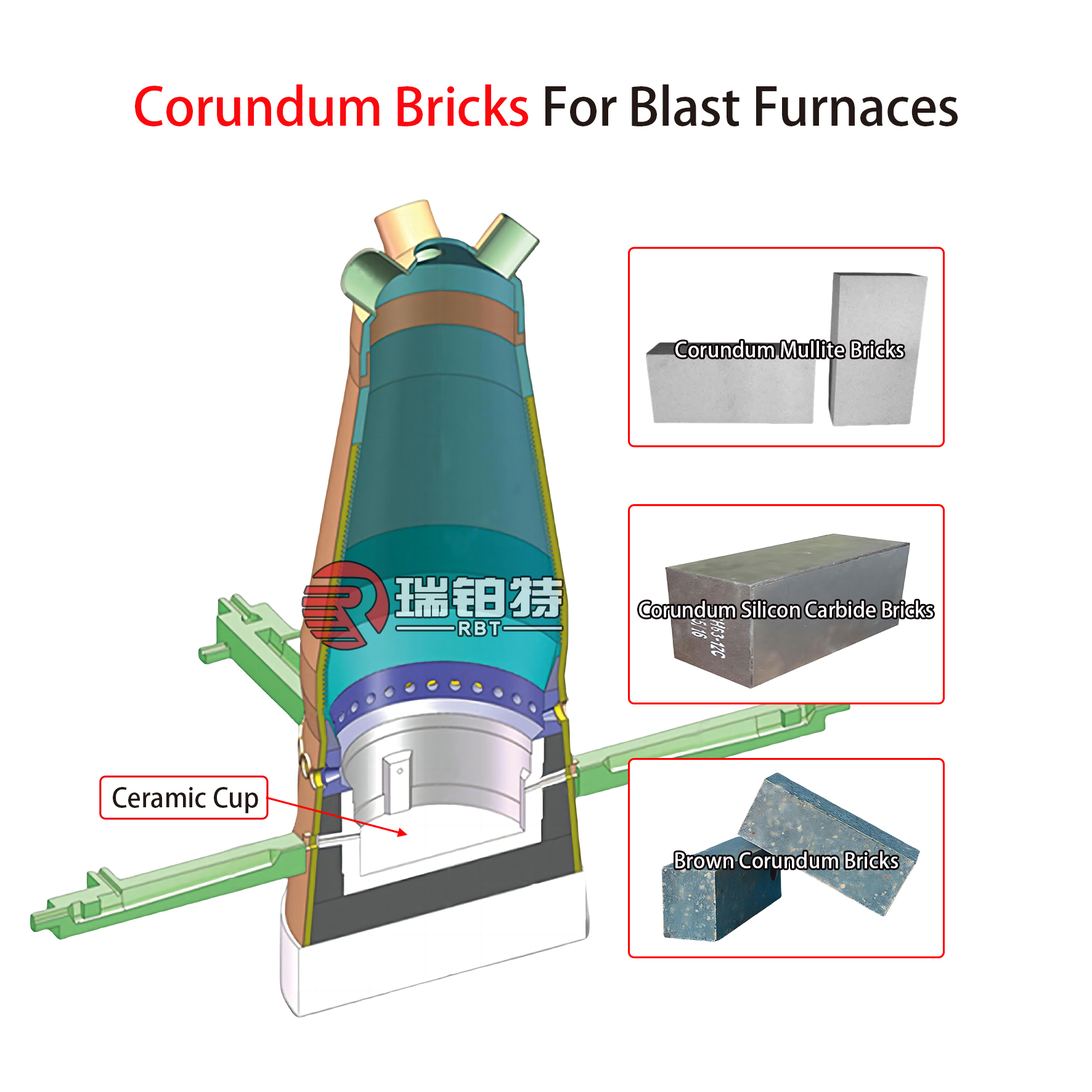

Litšebeliso tsa Litene tsa Corundum:

Indasteri ea Tšepe:E sebelisoa bakeng sa masela a lisebelisoa tsa ho qhibilihisa tse nang le mocheso o phahameng tse kang li-converter, lionto tsa motlakase, le lionto tsa ho hloekisa, hammoho le likarolo tse kang li-slide, li-stopper, le litsamaiso tsa ho tšela bakeng sa ho lahla ka mokhoa o tsoelang pele.

Ho qhibilihisa tšepe e sa ferrous:E manehiloe ka lionto tsa ho qhibilihisa le ho hloekisa bakeng sa litšepe tse se nang tšepe tse kang aluminium, koporo le nikeli.

Indasteri ea Khalase:E sebediswa hangata ka diteneng tsa checker ka dikamoreng tsa regenerator le dikoung tsa ho tjhaja tsa dionto tse qhibilihisang khalase.

Indasteri ea samente:E kentsoe sebakeng sa ho besa mocheso o phahameng sa li-oven tse potolohang tsa samente.

Indasteri ea Lik'hemik'hale:E kentsoe ka har'a li-reactor tse nang le mocheso o phahameng le lionto tse petsohang.

Indasteri ea Matla:E kentsoe ka lisebelisoa tsa kalafo ea khase ea mosi e chesang haholo le li-gasifier.

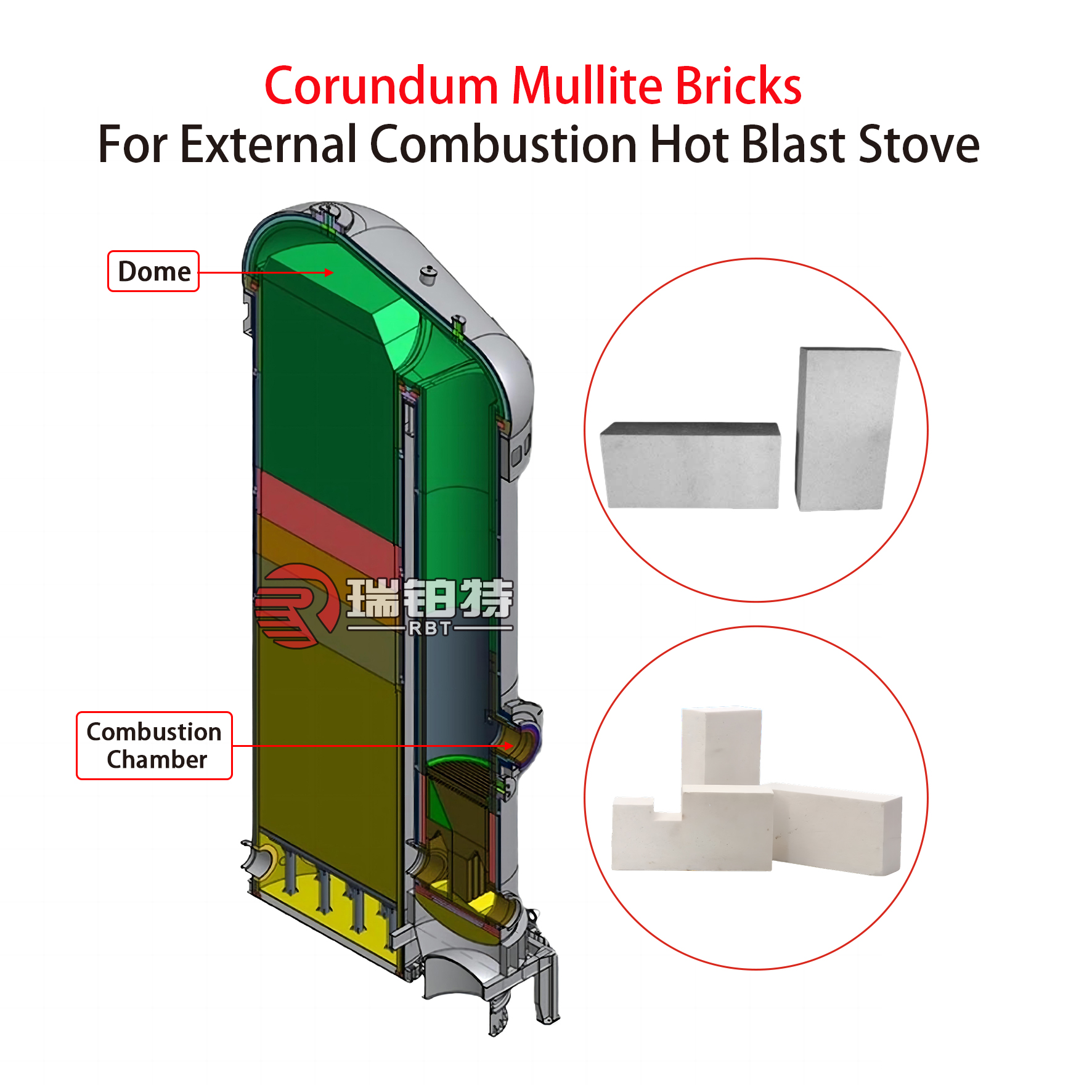

Litšebeliso tse ka Sehloohong tsa Litene tsa Corundum Mullite

Indasteri ea samente:E kentsoe sebakeng sa phetoho le precalciner ea li-oven tse potolohang tsa samente. Li ka mamella ho feto-fetoha ho hoholo ha mocheso ka har'a oven e potolohang ha li ntse li hanela likhase tse senyang tse hlahisoang ke ho bola ha thepa e tala ea samente.

Indasteri ea Khalase:Li sebelisoa liteneng tsa khalase tse hlahlobang mokhoa oa ho tsosolosa sebōpi le maboteng a ontong, li mamella ho feto-fetoha ha mocheso khafetsa 'me ha li senyehe habonolo ke khalase e qhibilihisitsoeng.

Indasteri ea Tšepe le Lik'hemik'hale:E loketse ho sebelisoa libakeng tse mahareng le tse tlase tsa mocheso oa lionto tsa tšepe tse se nang tšepe, masela a ho besa a mocheso o phahameng, le lisebelisoa tsa ho besa tse tsamaisang lik'hemik'hale indastering ea lik'hemik'hale, ho leka-lekanya matla le litlhoko tsa ho hanyetsa mocheso.

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e fumaneha Motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa e hanyetsang. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea ontong, theknoloji le thepa e hanyetsang kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a tekheniki a matla, boleng bo botle ba sehlahisoa, le botumo bo botle. Feme ea rona e akaretsa lihekthere tse fetang 200 'me tlhahiso ea selemo le selemo ea thepa e hanyetsang e bōpehileng joaloka e ka ba lithane tse 30000 'me thepa e hanyetsang e sa bōpehang joaloka e hanyetsang ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa e hanyetsang li kenyelletsa: thepa e hanyetsang alkaline; thepa e hanyetsang silicon ea aluminium; thepa e hanyetsang e sa bōpehang joaloka e thibelang; thepa e thibelang mocheso e thibelang mocheso; thepa e khethehileng e thibelang; thepa e sebetsang e thibelang bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Khafetsa

Na u hloka thuso? Etsa bonnete ba hore u etela liforamo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, fektheri ea rona e ikhethile ka ho hlahisa thepa e hanyetsang ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ea kamora thekiso.

Bakeng sa ts'ebetso e 'ngoe le e 'ngoe ea tlhahiso, RBT e na le sistimi e felletseng ea QC bakeng sa sebopeho sa lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa, 'me setifikeiti sa boleng se tla romelloa le thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho latela bongata, nako ea rona ea ho tlisa thepa e fapane. Empa re tšepisa ho e romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ehlile, re fana ka disampole tsa mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e ntle ka ho fetisisa ho latela boemo ba hau.

Re ntse re etsa thepa e hanyetsang mocheso ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le boiphihlelo bo bongata, re ka thusa bareki ho rala li-kiln tse fapaneng le ho fana ka tšebeletso ea ho emisa hang feela.