Khabide e Tala ea Silicon

Tlhahisoleseding ea Sehlahisoa

Lehlabathe le letala la silicon carbideke sesebelisoa se entsoeng ke motho se nang le mokhoa oa lik'hemik'hale oa SiC. E entsoe haholo-holo ka lehlabathe la quartz, petroleum coke (kapa coke ea mashala) le sawdust ka ho qhibilihisa mocheso o phahameng ka ontong e hanyetsang. Lehlabathe le letala la silicon carbide le na le 'mala o motala.'me e na le litšobotsi le lits'ebetso tse ngata tsa bohlokoa.

Tshebetso ea ts'ebetso

Bokgoni bo phahameng ba ho sila:Sebopeho sa dikarolwana le ho thatafala ha tsona di etsa hore e be le bokgoni bo botle ba ho sila, e leng se ka tlosang ditshila le lera la oxide kapele hodima karolo ya mosebetsi.

Thepa e ntle ea ho itlhoekisa:Boholo le sebopeho sa dikarolwana di a lekana mme di na le bohale ba lehare, e leng se netefatsang bokgoni ba yona ba ho itlhokomela bo leka-lekaneng jwalo ka thepa ya lehare la ho seha mme se netefatsa ho fokotswa ha thepa e sehilweng.

Ho ikamahanya le maemo ho hotle:E ka ikamahanya hantle le mefuta e fapaneng ya maro a ho seha ho ntlafatsa bokgoni ba ho sebetsa le boleng.

Matlotlo a 'Mele

| 'Mala | Botala |

| Sebopeho sa kristale | Poligone |

| Boima ba Mohs | 9.2-9.6 |

| Bothata bo bonyenyane | 2840~3320kg/mm² |

| Sebaka sa ho Qhibiliha | 1723 |

| Mocheso o phahameng ka ho fetisisa oa ho sebetsa | 1600 |

| Botebo ba 'Nete | 3.21g/cm³ |

| Bongata ba Bongata | 2.30g/cm³ |

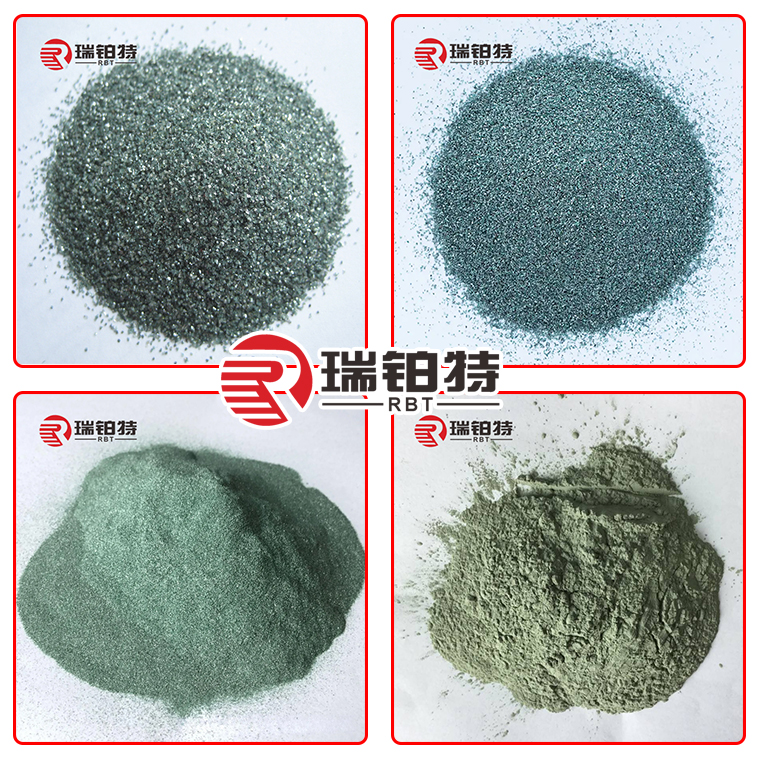

Litšoantšo tse qaqileng

Chate ea Papiso ea Boholo ba Grit

| Nomoro ea Grit. | Chaena GB2477-83 | Japane JISR 6001-87 | USA ANSI(76) | 欧洲磨料 FEPA(84) | 国际ISO(86) |

| 4 | 5600-4750 |

| 5600-4750 | 5600-4750 | 5600-4750 |

| 5 | 4750-4000 |

| 4750-4000 | 4750-4000 | 4750-4000 |

| 6 | 4000-3350 |

| 4000-3350 | 4000-3350 | 4000-3350 |

| 7 | 3350-2800 |

| 3350-2800 | 3350-2800 | 3350-2800 |

| 8 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 |

| 10 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 |

| 12 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 |

| 14 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 |

| 16 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 |

| 20 | 1180-1000 | 1180-1100 | 1180-1000 | 1180-1000 | 1180-1000 |

| 22 | 1000-850 | - | - | 1000-850 | 1000-850 |

| 24 | 850-710 | 850-710 | 850-710 | 850-710 | 850-710 |

| 30 | 710-600 | 710-600 | 710-600 | 710-600 | 710-600 |

| 36 | 600-500 | 600-500 | 600-500 | 600-500 | 600-500 |

| 40 | 500-425 | - | - | 500-425 | 500-425 |

| 46 | 425-355 | 425-355 | 425-355 | 425-355 | 425-355 |

| 54 | 355-300 | 355-300 | 355-297 | 355-300 | 355-300 |

| 60 | 300-250 | 300-250 | 297-250 | 300-250 | 300-250 |

| 70 | 250-212 | 250-212 | 250-212 | 250-212 | 250-212 |

| 80 | 212-180 | 212-180 | 212-180 | 212-180 | 212-180 |

| 90 | 180-150 | 180-150 | 180-150 | 180-150 | 180-150 |

| 100 | 150-125 | 150-125 | 150-125 | 150-125 | 150-125 |

| 120 | 125-106 | 125-106 | 125-106 | 125-106 | 125-106 |

| 150 | 106-75 | 106-75 | 106-75 | 106-75 | 106-75 |

| 180 | 90-63 | 90-63 | 90-63 | 90-63 | 90-63 |

| 220 | 75-53 | 75-53 | 75-53 | 75-53 | 75-53 |

| 240 | 75-53 | - | 75-53 | - |

Lethathamo la Sehlahisoa

| Boholo ba Lehlohlojane | Sebopeho sa Lik'hemik'hale% (Ka Boima) | ||

| SiC | F·C | Fe2O3 | |

| 12#-90# | ≥98.50 | ≤0.20 | ≤0.60 |

| 100#-180# | ≥98.00 | ≤0.30 | ≤0.80 |

| 220#-240# | ≥97.00 | ≤0.30 | ≤1.20 |

| W63-W20 | ≥96.00 | ≤0.40 | ≤1.50 |

| W14-W5 | ≥93.00 | ≤0.40 | ≤1.70 |

Kopo

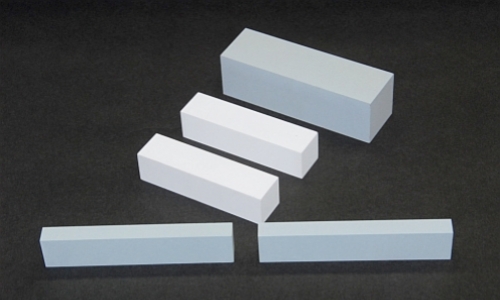

1. E khorofo:Carbide e tala ea silicon e sebelisoa haholo e le thepa e khorofong liindastering tse fapaneng, ho kenyeletsoa likoloi, lifofane, mesebetsi ea tšepe le mabenyane. E sebelisoa bakeng sa ho sila, ho seha le ho bentša litšepe tse thata le liseramike.

2. E hanelang:Carbide e tala ea silicon e boetse e sebelisoa e le thepa e hanyetsang lits'ebetsong tsa mocheso o phahameng joalo ka lionto le lionto ka lebaka la ho khanna ha eona mocheso o phahameng le katoloso e tlase ea mocheso.

3. Lisebelisoa tsa elektroniki:Carbide e tala ea silicon e sebelisoa e le thepa ea substrate bakeng sa lisebelisoa tsa elektroniki tse kang li-LED, lisebelisoa tsa motlakase le lisebelisoa tsa microwave ka lebaka la ho tsamaisa motlakase hantle le botsitso ba mocheso.

4. Matla a letsatsi:Carbide e tala ea silicon e sebelisoa e le thepa bakeng sa ho etsa liphanele tsa letsatsi ka lebaka la ho khanna ha eona mocheso o phahameng le katoloso e tlase ea mocheso, e thusang ho felisa mocheso o hlahisoang nakong ea ts'ebetso ea liphanele tsa letsatsi.

5. Tšepe:Carbide e tala ea silicon e sebelisoa e le sesebelisoa sa ho tlosa oxidation tlhahisong ea tšepe le tšepe. E thusa ho tlosa litšila tšepeng e qhibilihisitsoeng le ho ntlafatsa boleng ba sehlahisoa sa ho qetela.

6. Lisebelisoa tsa letsopa:Carbide e tala ea silicon e sebelisoa e le thepa e tala bakeng sa ho etsa li-ceramic tse tsoetseng pele joalo ka lisebelisoa tsa ho seha, likarolo tse sa tsofaleng, le likarolo tsa mocheso o phahameng ka lebaka la ho thatafala ha eona ho hoholo, matla a phahameng le botsitso bo botle ba mocheso.

Sephutheloana le Ntlo ea polokelo

| Sephutheloana | Mokotla oa 25KG | Mokotla oa 1000KG |

| Bongata | Lithane tse 24-25 | Lithane tse 24 |

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e fumaneha Motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa e hanyetsang. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea ontong, theknoloji le thepa e hanyetsang kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a tekheniki a matla, boleng bo botle ba sehlahisoa, le botumo bo botle. Feme ea rona e akaretsa lihekthere tse fetang 200 'me tlhahiso ea selemo le selemo ea thepa e hanyetsang e bōpehileng joaloka e ka ba lithane tse 30000 'me thepa e hanyetsang e sa bōpehang joaloka e hanyetsang ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa e hanyetsang li kenyelletsa:thepa e hanyetsang alkaline; thepa e hanyetsang silicon ea aluminium; thepa e sa bōpehang e hanyetsang; thepa e thibelang mocheso e thibelang mocheso; thepa e khethehileng e thibelang; thepa e sebetsang e thibelang bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Khafetsa

Na u hloka thuso? Etsa bonnete ba hore u etela liforamo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, fektheri ea rona e ikhethile ka ho hlahisa thepa e hanyetsang ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ea kamora thekiso.

Bakeng sa ts'ebetso e 'ngoe le e 'ngoe ea tlhahiso, RBT e na le sistimi e felletseng ea QC bakeng sa sebopeho sa lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa, 'me setifikeiti sa boleng se tla romelloa le thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho latela bongata, nako ea rona ea ho tlisa thepa e fapane. Empa re tšepisa ho e romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ehlile, re fana ka disampole tsa mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e ntle ka ho fetisisa ho latela boemo ba hau.

Re ntse re etsa thepa e hanyetsang mocheso ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le boiphihlelo bo bongata, re ka thusa bareki ho rala li-kiln tse fapaneng le ho fana ka tšebeletso ea ho emisa hang feela.