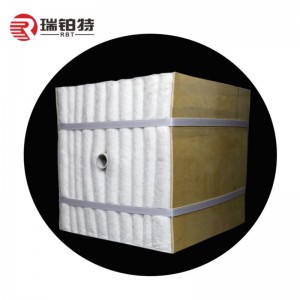

Likarolo tse bōpehileng ka Faeba ea boleng bo holimo bakeng sa Insulation

tlhaloso

Ho sebelisa k'hothone ea boleng bo holimo ea aluminium silicate fiber joalo ka thepa e tala, mokhoa oa ho bopa ka vacuum.E ka etsoa ka bongata bo fapaneng ba boholo ba 200-400kg/m3, libopeho tse fapaneng tsa litene, liboto, li-module, likarolo tse tloaelehileng tse entsoeng esale pele, li-burner, meropa le lihlahisoa tse ling tse khethehileng ho fihlela litlhoko tsa likarolo tse itseng tsa indasteri lihokelong tse khethehileng tsa tlhahiso, sebopeho le boholo li hloka ho etsa lisebelisoa tse khethehileng tsa abrasive.Lihlahisoa tsohle tse sa tloaelehang li na le shrinkage e tlase holim'a mocheso oa litšebeletso tsa tsona le ho boloka mocheso o phahameng oa mocheso, boima bo bobebe le ho hanyetsa tšusumetso.Lintho tse sa chesoang li ka sehoa kapa tsa etsoa ka mechine habonolo.Ha e ntse e sebelisoa, sehlahisoa se na le thepa e ntle e thibelang ho apara le e thibelang ho senya, 'me ha e senyehe ke litšepe tse ngata tse qhibilihisitsoeng.

Likaroloana

Likarolo tsa sehlahisoa: karolo e kholo ea fiber, boima bo bobebe, matla a phahameng, conductivity e tlase ea mocheso, ho hanyetsa mocheso oa mocheso, machining a bonolo, ho hanyetsa khoholeho ea moea, ho bonolo ho laola boima ba 'mele, khatello e itseng, ho tsitsisa, matla a flexural, polasetiki ea sebopeho se rarahaneng.

Kopo

Lihlahisoa li sebelisoa liindastering tse fapaneng tsa lisebelisoa tse futhumatsang mocheso holim'a lesela la mocheso, ho tšehetsa le ho kenya mocheso, lisebelisoa tsa ho kenya mocheso o phahameng oa mocheso oa liindasteri lerako la lerako, marulelo a leketlileng, ankora le monyako oa ontong, koloi ea kiln, indasteri ea lik'hemik'hale tsa petroleum e nang le mollo, likarolo tsa lesoba la ho shebella, groove, groove pad, molomo o monyane le tundish, kopano ea riser sleeve bakeng sa ho qhibiliha ha tšepe, boenjineri ba ho kenya letsoho ka suite efe kapa efe e rarahaneng ea geometry.

Index ea Lihlahisoa

| INDEX \PRODUCT | STD | HC | HA | HZ |

| Mocheso oa Mokhahlelo(℃) | 1260 | 1260 | 1360 | 1430 |

| Mocheso oa ho sebetsa(℃)≤ | 1050 | 1100 | 1200 | 1350 |

| Boima ba Bongata(kg/m3) | 200-400 | |||

| Thermal Conductivity(W/mk) | 0.086(400℃) 0.120(800℃) | 0.086(400℃) 0.110(800℃) | 0.092(400℃) 0.186(1000℃) | 0.092(400℃) 0.186(1000℃) |

| Phetoho e sa Feleng ea Linear(%) | -4/1000℃ | -3/1100℃ | -3/1200 ℃ | -3/1350 ℃ |

| Modulus of Rupture(MPa) | 6 | |||

| Al2O3(%) ≥ | 45 | 47 | 55 | 39 |

| Fe2O3(%) ≤ | 1.0 | 0.2 | 0.2 | 0.2 |

| SiO2(%) ≤ | 52 | 52 | 49 | 45 |

| ZrO2(%) ≥ | 11-13 | |||