Lehlabathe le lengata

Tlhahisoleseding ea Sehlahisoa

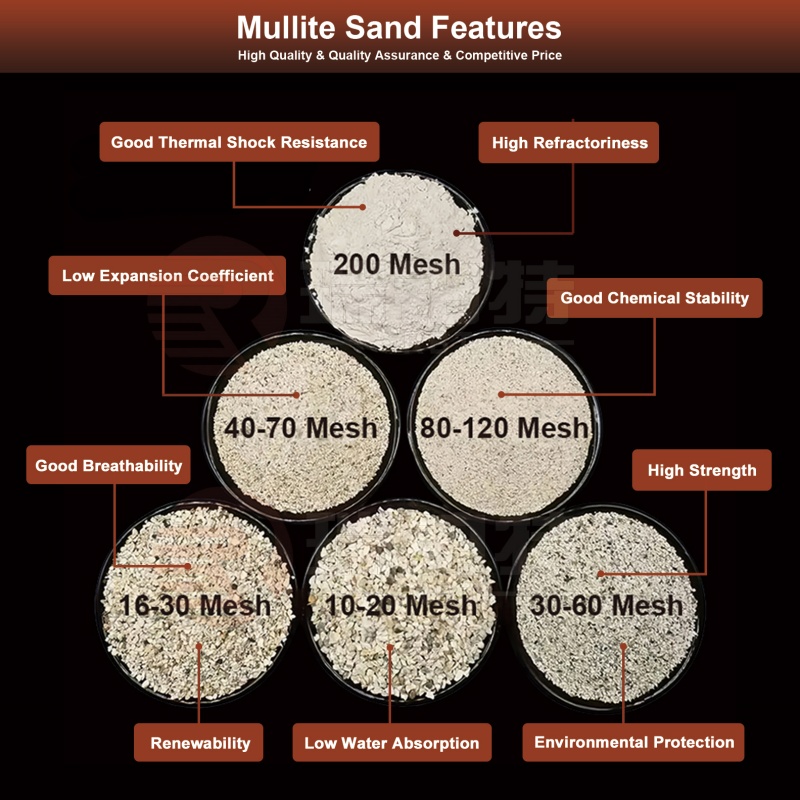

Lehlabathe le lengatake thepa e hanyetsang ya aluminium silicate, e sebediswang haholo tshebetsong ya ho lahla ka ho nepahala ha tshepe e sa ruseng. Ho hanyetsa ho ka ba di-degree tse ka bang 1750. Ha aluminium e le ngata lehlabatheng la mullite, tshepe e ba tlase, mme lerole le lenyenyane, boleng ba sehlahisoa sa lehlabathe la mullite bo ba betere. Lehlabathe la mullite le etswa ka ho sintering ka mocheso o phahameng wa kaolin.

Likaroloana:

1. Sebaka se phahameng sa ho qhibiliha, ka kakaretso pakeng tsa 1750 le 1860°C.

2. Botsitso bo botle ba mocheso o phahameng.

3. Koefficient e tlase ea katoloso ea mocheso.

4. Ho ba le botsitso bo phahameng ba lik'hemik'hale.

5. Kabo e utloahalang ea boholo ba likaroloana e lumella khetho le phetoho ho latela lits'ebetso tse fapaneng tsa ho lahla le litlhoko tsa ho lahla.

Lethathamo la Sehlahisoa

| Tlhaloso | Sehlopha sa Lijo tsa Mantsiboea | Sehlopha sa 1 | Sehlopha sa 2 |

| Al2O3 | 44%-45% | 43%-45% | 43%-50% |

| SiO2 | 50%-53% | 50%-54% | 47%-53% |

| Fe2O3 | ≤1.0% | ≤1.5% | ≤2.1% |

| K2O+Na2O | ≤0.5% | ≤0.6% | ≤0.8% |

| CaO | ≤0.4% | ≤0.5% | ≤0.5% |

| TiO2 | ≤0.3% | ≤0.7% | ≤0.3% |

| Soda ea Xaustic | ≤0.5% | ≤0.5% | ≤0.7% |

| Bongata ba Bongata | ≥2.5g/cm3 | ≥2.5g/cm3 | ≥2.45g/cm3 |

Likopo

Motheo oa ho lahla ka nepo ke tlhahiso ea khetla ea hlobo (mokhoa oa ho maneha paterone ea boka ka mekhahlelo e mengata ea thepa e hanyetsang ho etsa khetla ea kantle. Kamora hore paterone ea boka e qhibilihe, ho etsoa lesoba la ho tšela tšepe e qhibilihisitsoeng). Lehlabathe la mullite le sebelisoa haholo-holo e le motsoako o hanyetsang khetla ea hlobo 'me le sebelisoa likarolong tse fapaneng tsa khetla, haholo-holo ka tsela e latelang:

1. Khetla ea Bokaholimo (E Khetholla Boleng ba Bokaholimo ba ho Lahla ka ho Otloloha)

Mosebetsi:Lera la bokaholimo le kopana ka ho toba le foreimi 'me le tlameha ho netefatsa hore bokaholimo bo boreleli (ho qoba ho ba thata le ho petsoha) ha ka nako e ts'oanang le ho mamella tšusumetso ea pele ea tšepe e qhibilihisitsoeng.

2. Khetla ea Mokokotlo (E Fana ka Matla le ho Phefumoloha ka Kakaretso)

Mosebetsi:Khetla e ka morao ke sebopeho se nang le mekhahlelo e mengata ka ntle ho lera la bokaholimo. E tšehetsa matla a kakaretso a khetla ea hlobo (e thibela ho fetoha kapa ho putlama nakong ea ho tšolloa) ha ka nako e ts'oanang e netefatsa hore moea o khona ho hema (ho ntša likhase ka har'a lesoba le ho thibela masoba a ho lahla).

3. Likopo tse Ikhethileng bakeng sa Li-Casting tse Batloang Haholo

Li-castings tsa alloy tse mocheso o phahameng:tse kang mahare a turbine a enjene ea lifofane (lithemparetjha tse tšolohang tsa 1500-1600°C), li hloka hore khetla ea hlobo e mamelle mocheso o feteletseng. Ho se sebetse hantle ha lehlabathe la Mullite ho ka nkela lehlabathe la zircon le turang haholo (ntlha ea ho qhibiliha ea 2550°C, empa le theko e boima), le fihlela litlhoko tsa ho hanyetsa mocheso o phahameng ha ka nako e ts'oanang le fokotsa litšenyehelo.

Bakeng sa ho lahla tšepe e arabelang:joalo ka li-alloy tsa aluminium le li-alloy tsa magnesium (tse arabelang haholo 'me li arabela habonolo le SiO₂ lehlabatheng la quartz ho theha li-inclusions), botsitso ba lik'hemik'hale ba lehlabathe la mullite bo ka fokotsa reactivity le ho thibela ho thehoa ha "li-inclusions tsa oxidation" ka har'a casting.

Bakeng sa ho lahla ka nepo ho hoholo:joalo ka matlo a lebokose la gearbox la turbine ea moea (a ka bang boima ba lithane tse 'maloa), khetla ea hlobo e hloka matla a holimo a sebopeho. Lera le ka morao le entsoeng ka lehlabathe la mullite le binder le matla a holimo, le fokotsa kotsi ea ho atoloha le ho putlama ha hlobo.

4. Motsoako le Lisebelisoa tse ling tse Refractory

Tlhahisong ea 'nete, lehlabathe la mullite hangata le sebelisoa hammoho le lisebelisoa tse ling ho ntlafatsa ts'ebetso ea khetla ea hlobo:

Motsoako le lehlabathe la zircon:Lehlabathe la zircon le sebediswa e le lera la bokahodimo (ho netefatsa hore bokahodimo bo fihla qetellong e hodimo) le lehlabathe la mullite e le lera la ka morao (ho fokotsa ditjeo). Sena se loketse bakeng sa ho tjhesa ka dihlahiswa tse nang le ditlhoko tse phahameng haholo tsa bokahodimo, jwalo ka dikarolo tsa sefofane.

E kopantsoe le lehlabathe la quartz:Bakeng sa di-cast tse nang le ditlhoko tse tlase tsa mocheso (jwalo ka alloy ya koporo, ntlha ya ho qhibiliha ya 1083℃), e ka nka sebaka sa lehlabathe la quartz ka karolo e itseng mme ya sebedisa katoloso e tlase ya lehlabathe la mullite ho fokotsa mapetso a khetla.

| Ts'ebetso ea Litšupiso Bakeng sa ho Etsa Likhetla ka Potlako | ||

| Lero le akaretsang la bokaholimo, phofo ea zirconium | 325 letlooeng + silika sol | Lehlabathe: lehlabathe la zirconium 120 letlooeng |

| Lera le ka morao la lera | Letlooeng la 325+silicone sol+mullite phofo letlooeng la 200 | Lehlabathe: lehlabathe la mullite 30-60 letlooeng |

| Lera la matlafatso | Phofo ea Mullite 200 letlooeng + silika sol | Lehlabathe: lehlabathe la mullite le nang le letlooeng la 16-30 |

| Ho tiisa slurry | Phofo ea Mullite 200 letlooeng + silika sol | _ |

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e fumaneha Motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa e hanyetsang. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea ontong, theknoloji le thepa e hanyetsang kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a tekheniki a matla, boleng bo botle ba sehlahisoa, le botumo bo botle. Feme ea rona e akaretsa lihekthere tse fetang 200 'me tlhahiso ea selemo le selemo ea thepa e hanyetsang e bōpehileng joaloka e ka ba lithane tse 30000 'me thepa e hanyetsang e sa bōpehang joaloka e hanyetsang ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa e hanyetsang li kenyelletsa: thepa e hanyetsang alkaline; thepa e hanyetsang silicon ea aluminium; thepa e hanyetsang e sa bōpehang joaloka e thibelang; thepa e thibelang mocheso e thibelang mocheso; thepa e khethehileng e thibelang; thepa e sebetsang e thibelang bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Khafetsa

Na u hloka thuso? Etsa bonnete ba hore u etela liforamo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, fektheri ea rona e ikhethile ka ho hlahisa thepa e hanyetsang ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ea kamora thekiso.

Bakeng sa ts'ebetso e 'ngoe le e 'ngoe ea tlhahiso, RBT e na le sistimi e felletseng ea QC bakeng sa sebopeho sa lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa, 'me setifikeiti sa boleng se tla romelloa le thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho latela bongata, nako ea rona ea ho tlisa thepa e fapane. Empa re tšepisa ho e romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ehlile, re fana ka disampole tsa mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e ntle ka ho fetisisa ho latela boemo ba hau.

Re ntse re etsa thepa e hanyetsang mocheso ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le boiphihlelo bo bongata, re ka thusa bareki ho rala li-kiln tse fapaneng le ho fana ka tšebeletso ea ho emisa hang feela.