Selelekela

Liindastering tse nang le mocheso o phahameng-ho tloha ho tšepe ho ea ho tlhahiso ea likhalase-lisebelisoa tsa refractory ke mokokotlo oa ts'ebetso e sireletsehileng le e sebetsang hantle. Har'a tsena,litene tse ngataba hlahelletseng bakeng sa botsitso ba bona bo ikhethang ba mocheso, ho hanyetsa kutu, le matla a mochini. Ho utloisisa likarolo tsa bona le lits'ebetso ho bohlokoa bakeng sa likhoebo tse batlang ho ntlafatsa bophelo ba lisebelisoa le ho fokotsa litšenyehelo tsa ts'ebetso. Sengoliloeng sena se qhekella mefuta ea bohlokoa ea litene tsa mullite le ts'ebeliso ea tsona ea 'nete ea lefats'e, ho u thusa ho etsa liqeto tse nepahetseng bakeng sa litlhoko tsa hau tsa indasteri.

Sehlopha sa litene tsa Mullite

Litene tsa Mullite li arotsoe ho ipapisitsoe le lits'ebetso tsa tlhahiso le likarolo tse ekelitsoeng, e 'ngoe le e' ngoe e etselitsoe litlhoko tse ikhethang tsa indasteri.

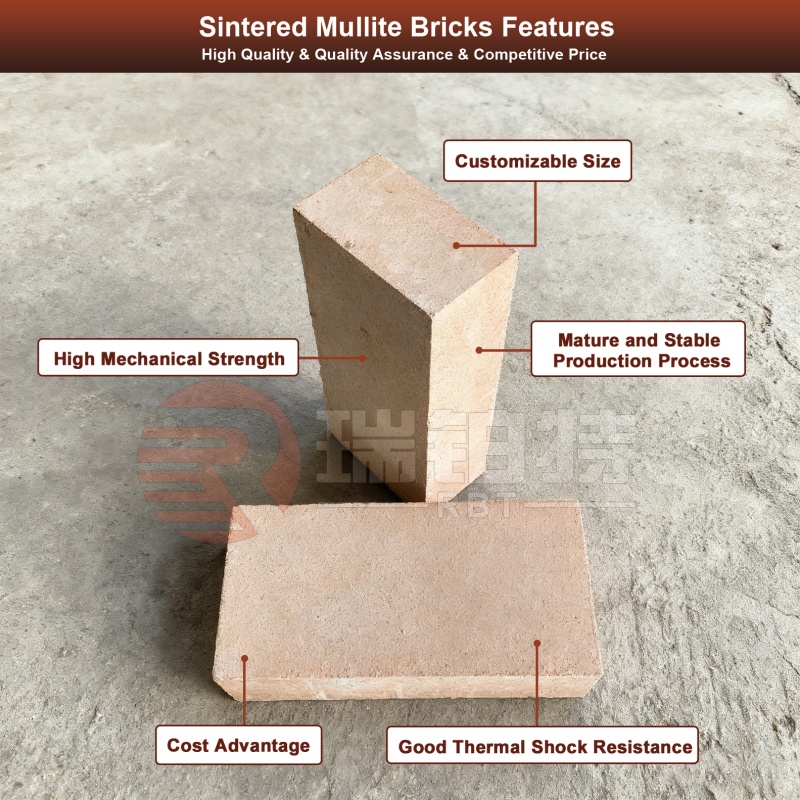

1. Sintered Mullite Bricks

E entsoe ka ho kopanya li-alumina tse hloekileng le silika, ho bōpa motsoako, le ho o tšela ka mocheso o ka holimo ho 1600 ° C, litene tsa sintered mullite li ithorisa ka sebopeho se teteaneng le porosity e tlaase (hangata e ka tlase ho 15%). Litšobotsi tsena li ba fa khanyetso e ntle ea ho apara le ho hanyetsa mocheso oa mocheso-e loketseng tikoloho e nang le ho fetoha ha mocheso khafetsa. Litšebeliso tse tloaelehileng li kenyelletsa lirala tsa litofo tsa ceramic, litofo tse chesang tsa sebōpi, le likamore tse tukang tsa boiler.

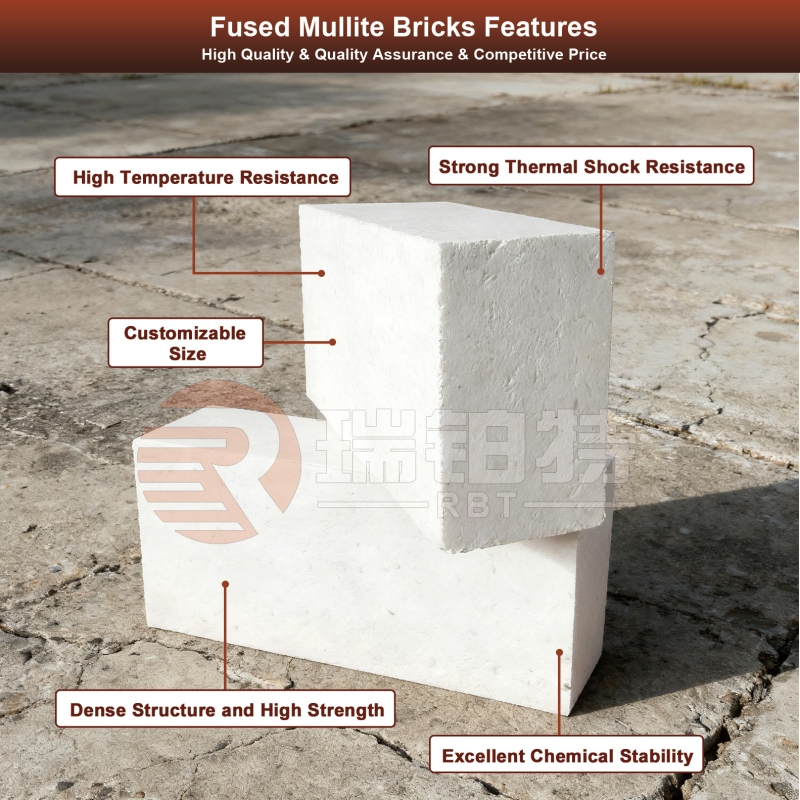

2. Litene tsa Mullite tse Fused-cast

E hlahisoa ka ho qhibiliha lisebelisoa tse tala (alumina, silica) ka sebōping sa motlakase sa arc (ho feta 2000 ° C) le ho lahlela motsoako o qhibilihisitsoeng ka har'a hlobo, litene tsa mullite tse entsoeng ka fused-cast li na le litekanyetso tse sa hloekang haholo le bohloeki bo phahameng ba kristale. Ho hanyetsa ha bona khoholeho ea lik'hemik'hale (mohlala, likhalase tse entsoeng ka ho qhibilihisoa kapa li-slags) ho ba etsa khetho e phahameng bakeng sa lisebelisoa tse nchafatsang mollo oa khalase, libate tsa litene tsa khalase tse phaphametseng, le lisebelisoa tse ling tse pepesehileng mecheng ea litaba e matla e qhibilihisitsoeng.

3. Litene tsa Mullite tse bobebe

E entsoe ka ho eketsa li-pore-forming agents (mohlala, sawdust, graphite) nakong ea tlhahiso, litene tse bobebe tsa mullite li na le porosity ea 40-60% le boima bo tlaase haholo ho feta mefuta e entsoeng ka sintered kapa fused-cast. Monyetla oa bona o ka sehloohong ke conductivity e tlaase ea mocheso (0.4-1.2 W / (m·K)), e fokotsang tahlehelo ea mocheso. Li sebelisoa haholo e le likarolo tsa ho futhumatsa liontong, liboping le lisebelisoa tsa kalafo ea mocheso, moo boima ba 'mele le matla a matla e leng tsona tse tlang pele.

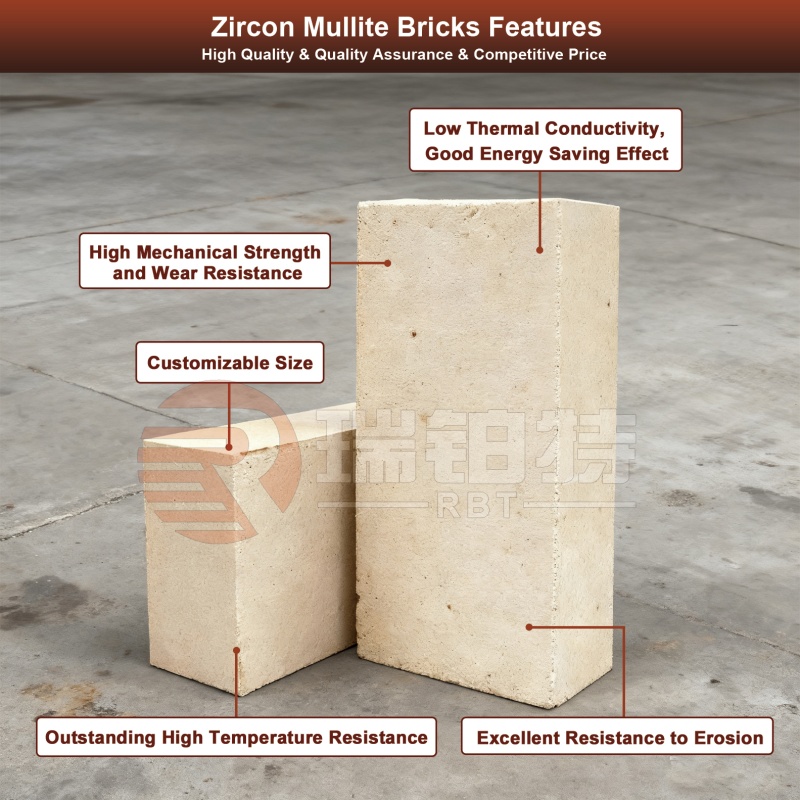

4. Litene tsa Zircon Mullite

Ka ho kenyelletsa zircon (ZrSiO₄) ka har'a motsoako oa lihlahisoa tse tala, litene tsa zircon mullite li fumana ts'ebetso e ntlafetseng ea mocheso o phahameng-li khona ho mamella mocheso ho fihlela ho 1750 ° C le ho hanela khoholeho ea mobu ho tloha ho slags ea acidic. Sena se li etsa hore li tšoanele libaka tse thata tse kang libopi tse qhibilihisang tšepe tse se nang ferrous (mohlala, lisele tse fokotsang aluminium) le libaka tsa ho chesa sebōpi sa rotary samente.

Lisebelisoa tsa Mullite Bricks

Ho feto-fetoha ha litene tsa Mullite ho etsa hore e be tsa bohlokoa haholo liindastering tse ngata tse nang le mocheso o phahameng.

1. Indasteri ea tšepe

Tlhahiso ea tšepe e kenyelletsa mocheso o feteletseng (ho fihla ho 1800 ° C) le li-slags tse senyang. Litene tsa sintered mullite li tsamaisa litofo tse chesang, moo ho hanyetsa ha tsona ho thibelang ho phatloha ho tloha ho futhumala ka potlako / pholileng. Mefuta e fapaneng ea li-fused cast e sireletsa li-ladle le li-tundishes, e fokotsa khoholeho ea mobu le ho lelefatsa bophelo ba lisebelisoa ka 20-30% ha e bapisoa le litšiea tsa setso.

2. Indasteri ea Samente

Likamore tsa samente tsa rotary li sebetsa ho 1450-1600 ° C, 'me li-slags tsa alkaline li baka kotsi e kholo ea khoholeho. Litene tsa Zircon mullite li tsamaisa sebaka se tukang sa sebōpi, li hanela litlhaselo tsa alkali le ho boloka botsitso ba sebopeho. Litene tse bobebe tsa mullite li boetse li sebetsa joalo ka likarolo tsa insulation, li fokotsa tšebeliso ea matla ka 10-15%.

3. Indasteri ea Khalase

Khalase e qhibilihisitsoeng (1500-1600 ° C) e senya haholo, 'me e etsa hore litene tsa mullite tse fused-cast e be tsa bohlokoa bakeng sa lisebelisoa tse nchafatsang tsa sebōpi sa khalase le lirala tsa tanka. Li thibela tšilafalo ea khalase le ho lelefatsa nako ea ho sebetsa ho fihlela lilemo tse 5-8, ho tloha ho lilemo tse 3-5 ka lisebelisoa tse ling.

4. Liindasteri tse ling

Ka ho qhibilihisa tšepe e se nang ferrous (aluminium, koporo), litene tsa zircon mullite li hanela tšepe e qhibilihisitsoeng le khoholeho ea slag. Lik'hemik'haleng tsa petrole, litene tsa sintered mullite li tsamaisa libopi tse qhekellang ka lebaka la botsitso ba tsona ba mocheso. Ka li-ceramics, litene tse bobebe tsa mullite li kenya liipone, li fokotsa tšebeliso ea matla

Qetello

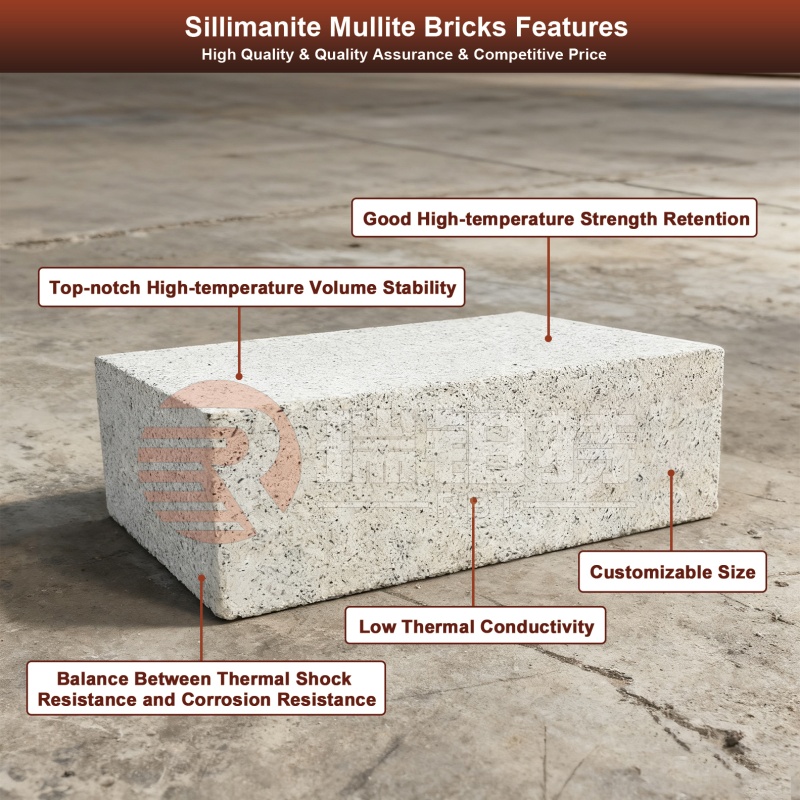

Mefuta e fapaneng ea litene tsa Mullite — e entsoeng ka sintered, fused-cast, lightweight, le zircon — e fihlela litlhoko tse ikhethang tsa liindasteri tse nang le mocheso o phahameng. Ho tloha ho matlafatseng bokhoni ba sebōpi sa tšepe ho ea ho lelefatsa bophelo ba sebopi sa khalase, ba fana ka melemo e bonahalang: nako e telele ea lisebelisoa, litšenyehelo tse tlase tsa matla le nako e fokotsehileng. Ha liindasteri li ntse li phehella tlhahiso e phahameng le ho tšoarella, litene tsa mullite li tla lula e le tharollo ea bohlokoa. Khetha mofuta o nepahetseng bakeng sa kopo ea hau, 'me u notlolle bokhoni ba bona bo felletseng.

Nako ea poso: Oct-31-2025