Lefapheng la liindasteri tse nang le mocheso o phahameng oa mocheso, ts'ebetso ea lisebelisoa tsa sebōpi se ama ka ho toba katleho ea tlhahiso le boleng ba sehlahisoa. Joaloka moemeli oa lisebelisoa tse phahameng tsa ts'ebetso, litene tsa spinel tsa magnesia-alumina, tse nang le thepa ea tsona e ntle ka ho fetisisa, li fetohile khetho e ntle bakeng sa liindasteri tse kang tšepe, khalase le samente ho hanela khoholeho ea mocheso o phahameng le ho lelefatsa bophelo ba lisebelisoa, ho fana ka tšehetso e ka tšeptjoang bakeng sa tlhahiso ea indasteri e phahameng ea mocheso.

Ho Tsamaisa Indasteri ka Ts'ebetso e Ikhethileng

Magnesia-alumina spinel litene li entsoe ka magnesia le aluminium oxide ka mekhoa e khethehileng. Sebopeho sa bona se ikhethang sa kristale se ba fa melemo e matla ea ts'ebetso. Litene tsena li bontša ho hanyetsa mocheso o phahameng, tse khonang ho mamella mocheso o feteletseng ho fihla ho 1800 ° C. Esita le libakeng tse nang le mocheso o phahameng ka nako e telele, li boloka litšobotsi tse tsitsitseng tsa 'mele le lik'hemik'hale, ka katleho li thibela ho senyeha ha masela a mollo a bakoang ke mocheso o phahameng.

Ho hanyetsa mocheso oa mocheso ke tšobotsi e tsotehang ea litene tsa magnesia-alumina spinel. Nakong ea potoloho ea khafetsa ea ho futhumatsa le ho pholile ha libotlolo, lisebelisoa tse tloaelehileng tsa refractory li tloaetse ho phatloha le ho phatloha ka lebaka la khatello ea mocheso. Leha ho le joalo, ka coefficient ea bona e tlase ea ho atolosoa ha mocheso le boima bo botle, litene tsa magnesia-alumina spinel li ka fokotsa ka katleho liphello tsa khatello ea mocheso, ho fokotsa haholo kotsi ea tšenyo ea mocheso oa mocheso, ho lelefatsa bophelo ba tšebeletso, le ho fokotsa nako ea ho chesa mollo bakeng sa tlhokomelo.

Magnesia-alumina spinel litene le tsona li sebetsa hantle haholo ts'ireletsong ea khoholeho ea lik'hemik'hale. Li na le khanyetso e babatsehang ea alkaline le acidic slag, hammoho le likhase tse phahameng tsa mocheso, ka katleho li thibela ho kenella ha lintho tse kotsi le ho sireletsa tšireletso ea moralo oa libotlolo. Ebang ke tikolohong e nang le alkaline e ngata haholo ea ho qhibilihisa tšepe kapa moeeng o nang le asiti e phahameng ea mocheso oa tlhahiso ea likhalase, li ka phethahatsa mesebetsi ea tsona ea tšireletso ka mokhoa o tsitsitseng.

Likopo tse Tebileng ho Fetisisa Liindasteri tse ngata

Lefapheng la tšepe, litene tsa magnesia-alumina spinel li sebelisoa haholo libakeng tsa bohlokoa tsa li-converter, li-ladle le li-tundishes. Nakong ea ho etsa litšepe tsa converter, ba ka mamella ho hloekisoa le khoholeho ea tšepe e entsoeng ka mocheso o phahameng oa mocheso le slag, ho netefatsa botšepehi ba lesela la converter. Ha li sebelisoa ka lilae le li-tundishes, li ka fokotsa karabelo lipakeng tsa tšepe e qhibilihisitsoeng le lisebelisoa tsa lesela, tsa ntlafatsa bohloeki ba tšepe e qhibilihisitsoeng, le ho ntlafatsa boleng ba tšepe. Ka mor'a hore khoebo e kholo ea tšepe e amohele litene tsa magnesia-alumina spinel, bophelo ba tšebeletso ea li-ladle tsa eona bo ile ba eketseha ho tloha ka karolelano ea mocheso oa 60 ho ea ho mocheso oa 120, ho fokotsa haholo litšenyehelo tsa tlhahiso.

Lefapheng la tlhahiso ea likhalase, litene tsa magnesia-alumina spinel ke lisebelisoa tse ratoang bakeng sa likarolo tsa bohlokoa tsa likhalase tsa khalase. Libakeng tse chesang le li-regenerator tsa likhalase tse qhibilihisang likhalase, li khona ho mamella khoholeho ea likhalase tse nang le mocheso o phahameng oa mocheso le ho hahloa ha likhase tse nang le mocheso o phahameng, ho boloka botsitso ba sebopeho sa sebōpi, ho fokotsa maqhubu a tlhokomelo ea sebōpi, le ho ntlafatsa tsoelo-pele le botsitso ba tlhahiso ea khalase. Kamora ho sebelisa litene tsa spinel tsa magnesia-alumina, potoloho ea ntlafatso ea libono tsa khalase e ka atolosoa ka lilemo tse 2 - 3, e leng ho matlafatsang melemo ea moruo ea likhoebo.

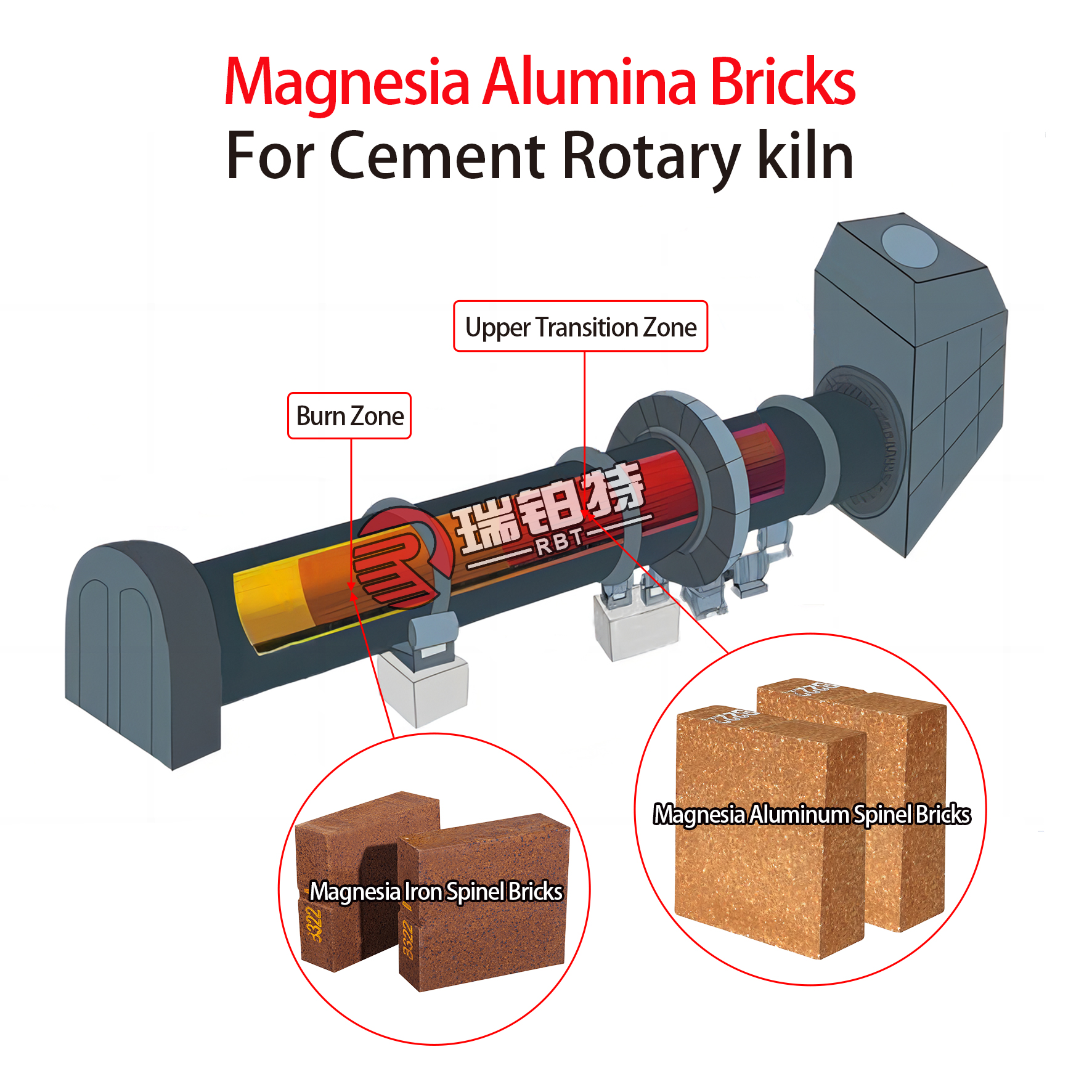

Nakong ea tlhahiso ea samente, tikoloho e nang le mocheso o phahameng oa libotlolo tsa rotary e beha litlhoko tse thata holim'a lisebelisoa tse refractory. Ka ho hanyetsa ha bona mocheso o phahameng, ho hanyetsa abrasion, le botsitso bo botle ba lik'hemik'hale, litene tsa magnesia-alumina spinel li phetha karolo ea bohlokoa sebakeng sa phetoho le libaka tse tukang tsa libono tsa rotary, ho netefatsa ts'ebetso e tsitsitseng ea 'mele oa sebōpi tlas'a mocheso o phahameng le maemo a boima bo phahameng le ho kenya letsoho ho eketsa tlhahiso ea samente le boleng bo ntlafetseng.

Tataiso ea ho Reka ea Setsebi

Ha u khetha litene tsa magnesia-alumina spinel, lintlha tse latelang tsa bohlokoa li lokela ho hatisoa: Ntlha ea pele, ela hloko lik'hemik'hale le metsoako ea diminerale ea thepa. Magnesia a phahameng a hloekileng le lisebelisoa tse tala tsa aluminium oxide li ka netefatsa ts'ebetso e tsitsitseng ea litene. Ea bobeli, tsepamisa maikutlo ho matšoao a ts'ebetso ea 'mele ea lihlahisoa, joalo ka bongata ba bongata, ho bonahala eka ke porosity, le matla a ho sithabela a batang mocheso oa kamore. Matšoao ana a bonahatsa ka ho toba boleng le ho tšoarella ha litene. Ntlha ea boraro, hlahloba mokhoa oa tlhahiso le mokhoa oa ho laola boleng ba bafani ba thepa. Khetha barekisi ba nang le lisebelisoa tse tsoetseng pele tsa tlhahiso, lits'ebetso tse felletseng tsa tlhahlobo, le boiphihlelo bo bongata ba indasteri ho netefatsa boleng bo tšepahalang ba sehlahisoa. Ho phaella moo, ho ea ka maemo a khethehileng a ts'ebetso, ho nepahala ha dimensional le ho feto-fetoha ha sebopeho sa litene ho boetse ho lokela ho nkoa e le ho etsa bonnete ba hore ho hahoa le ho kenngoa hamonate.

Ka ts'ebetso ea bona e ikhethang le lits'ebetso tse pharalletseng, litene tsa spinel tsa magnesia-alumina li fetohile lisebelisoa tsa bohlokoa tse sebetsang hantle haholo indastering ea mocheso o phahameng. Ebang ke ho ntlafatsa katleho ea tlhahiso, ho fokotsa litšenyehelo, kapa ho netefatsa boleng ba sehlahisoa, ba ka fana ka tharollo e tšepahalang bakeng sa likhoebo. Ikopanye le rona hona joale ho fumana tlhaiso-leseling ea sehlahisoa sa profeshenale le lits'ebeletso tse ikhethileng, 'me re ke re sireletse tlhahiso ea hau ea liindasteri ea mocheso o phahameng!

Nako ea poso: Jun-23-2025