Sebakeng se seholo sa tlhahiso ea liindasteri tse nang le mocheso o phahameng oa mocheso, lishelefo tsa kiln, e le likarolo tsa mantlha tse tsamaisang thepa bakeng sa ts'ebetso e phahameng ea mocheso, ts'ebetso ea bona e ama ka ho toba katleho ea tlhahiso, boleng ba sehlahisoa le litšenyehelo tsa tlhahiso. Leha ho le joalo, ha lishelefo tsa setso tsa sebōpi li tobana le maemo a thata a kang mocheso o sa khaotseng, ho tsosoa ha mocheso khafetsa, ho roala lintho tse bonahalang, le ho bola ha lik'hemik'hale, hangata li kopana le mathata a kang bophelo bo bokhutšoanyane ba tšebeletso, ho senyeha le ho senya, le litšenyehelo tse phahameng tsa tlhokomelo, tse thibelang haholo ts'ebetso e tsitsitseng ea tlhahiso. Ho hlaha ha lishelefo tsa silicon carbide kiln, ka melemo ea tsona e ntle ea ts'ebetso, ho tlisitse katleho e kholo tlhahisong ea indasteri e nang le mocheso o phahameng oa mocheso.

Melemo e Ikhethileng ea Silicon Carbide Kiln Shelves

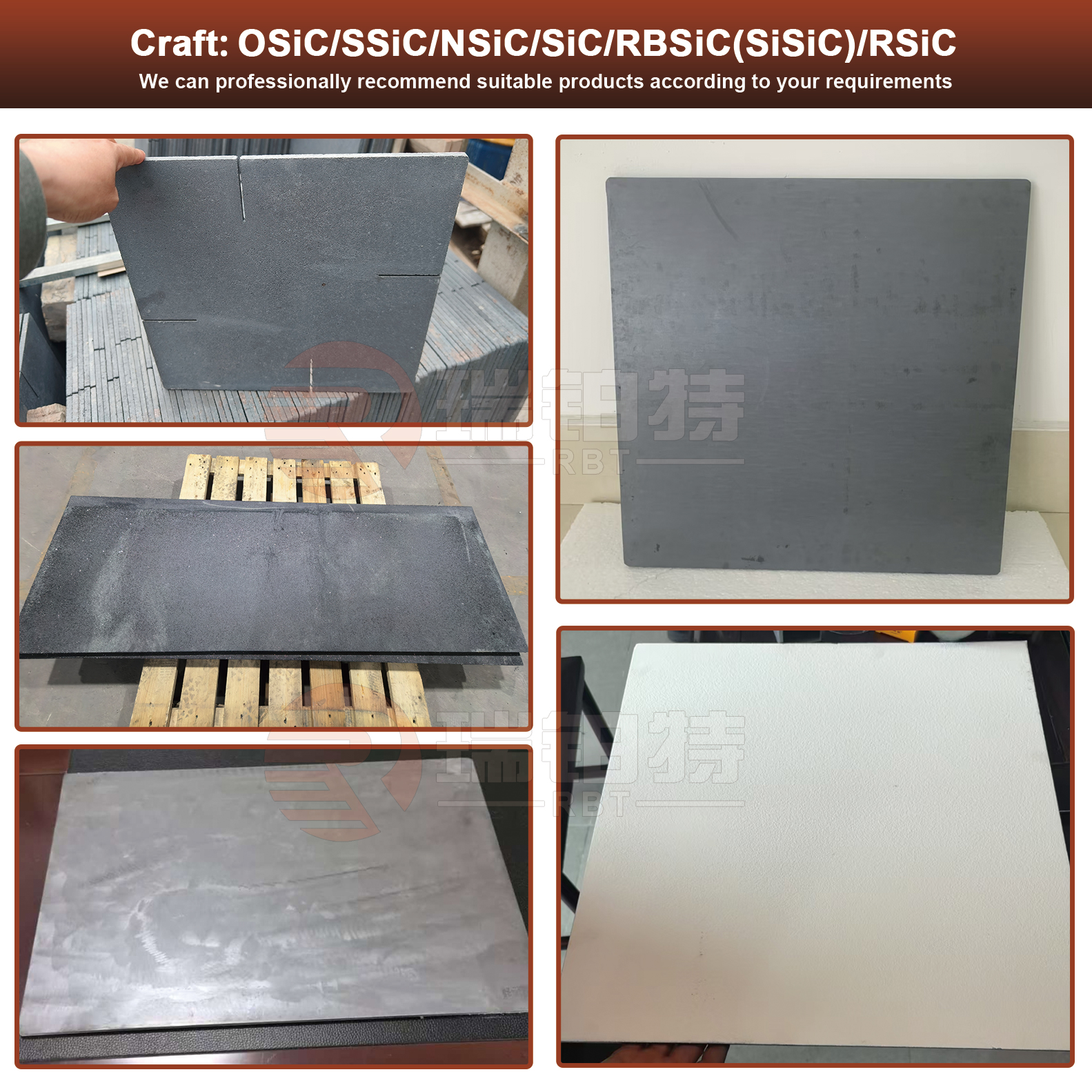

Lishelefo tsa silicon carbide kiln li ka fetoha tse ratoang haholo indastering ea mocheso o phahameng ka lebaka la melemo e mengata e fanoeng ke thepa ea bona e ikhethang:

Khanyetso e Phahameng ea Mocheso o Phahameng: Sesebelisuoa sa silicon carbide ka boeona se na le sebaka se phahameng haholo sa ho qhibiliha, se nolofalletsang lishelefo tsa silicon carbide ho mamella maemo a mocheso o phahameng ka holimo ho 1600 ° C. Li sebetsa ka mokhoa o tsitsitseng nakong ea ts'ebetso ea nako e telele ea mocheso o phahameng 'me li ke ke tsa nolofatsa, tsa holofatsa kapa tsa ba le litaba tse ling ka lebaka la mocheso o phahameng, ho netefatsa ho ts'oana le botsitso ba mokhoa oa ho futhumatsa thepa ka sebōping.

Hantle-ntle ea Wear Resistance:Silicon carbide e na le boima bo phahameng haholo, 'me khanyetso ea eona ea ho roala e phahame haholo ho feta lishelefo tsa setso tse entsoeng ka letsopa, aluminium e phahameng le lisebelisoa tse ling. Nakong ea ho kenya le ho tsamaisa thepa, lishelefo tsa silicon carbide kiln li khona ho hanela likhohlano le tšusumetso ea thepa, tsa fokotsa ho roala ha holim'a metsi, kahoo li boloka ho bata ha thepa le ho netefatsa hore thepa e futhumala.

E Ikhethang ea Thermal Shock Resistance:Tlhahisong ea liindasteri tse nang le mocheso o phahameng, lishelefo tsa kiln li atisa ho futhumala ka potlako le mekhoa ea ho pholisa, e leng se etsang hore ho be le litlhoko tse phahameng haholo ho hanyetsa mocheso oa mocheso. Lishelefo tsa silicon carbide kiln li na le coefficient e tlase haholo ea katoloso ea mela le ts'ebetso e ntle ea mocheso, e ka thibelang khatello ea mocheso e bakoang ke liphetoho tsa tšohanyetso tsa mocheso le ho fokotsa haholo ho hlaha ha ho phatloha, ho phatloha le liketsahalo tse ling.

Bophelo bo Bolelele ba Ts'ebeletso:Ka lebaka la thepa e ntle e kaholimo, bophelo ba lits'ebeletso tsa lishelefo tsa silicon carbide kiln bo bolelele ho feta ba lishelefo tsa setso tsa sebōpi. Tlas'a maemo a ts'oanang a ts'ebetso, bophelo ba bona ba ts'ebeletso bo ka ba bolelele ba makhetlo a 3-5 kapa ho feta ba lishelefo tsa sebōpi sa setso, ho fokotsa haholo makhetlo a ho fetola lishelefo le tahlehelo ea tlhahiso le litšenyehelo tsa basebetsi tse bakoang ke ho koaloa ha thepa e ncha.

Good Chemical Stability:Silicon carbide e na le khanyetso e matla ho mecha ea litaba e senyang joalo ka li-acids le alkalis. Libōping tse ling tse nang le mocheso o phahameng o nang le likhase tse senyang kapa thepa, e ka boloka metsoako ea lik’hemik’hale e tsitsitse ’me ha ho bonolo hore e senngoe ke lik’hemik’hale, e leng ho tiisang hore sebōpi se sebetsa ka mokhoa o tsitsitseng.

Ts'ebetso e ntle haholo ea lishelefo tsa silicon carbide kiln e li nolofalelitse ho sebelisoa haholo masimong a mangata a mocheso o phahameng oa mocheso.Ka indasteri ea ceramic, ebang ke ho chesoa ha lirafshoa tsa letsatsi le letsatsi, lirafshoa tsa meralo, kapa li-ceramics tse khethehileng, lishelefo tsa silicon carbide kiln li ka mamella tikoloho e thata ea libotlolo tsa mocheso o phahameng, ho netefatsa ho futhumala ho tšoanang ha likheo tsa ceramic nakong ea ts'ebetso ea ho thunya, le ho ntlafatsa litekanyetso tsa lihlahisoa tsa lihlahisoa.Ka indasteri ea metallurgical, li ka sebelisoa lihokelong tsa ho sebetsa ka mocheso o phahameng joalo ka sintering le smelting ea thepa ea tšepe, ho hanyetsa khoholeho ea tšepe e qhibilihisitsoeng le slag.Ka indasteri ea elektronike, bakeng sa ho lokisoa ha mocheso o phahameng oa lihlahisoa tse nepahetseng tse kang li-ceramics tsa elektronike le lisebelisoa tsa semiconductor, botsitso le bohloeki ba lishelefo tsa silicon carbide kiln li ka finyella litlhoko tse tiileng tsa tlhahiso. Ntle le moo, lishelefo tsa silicon carbide kiln le tsona li phetha karolo ea bohlokoa tlhahisong ea mocheso o phahameng liindastering tse joalo ka likhalase le lisebelisoa tsa refractory.

Ka ho khetha lishelefo tsa rona tsa silicon carbide kiln, u tla fumana lihlahisoa tsa boleng bo holimo le litiisetso tse felletseng tsa litšebeletso. Re sebelisa mekhoa e tsoetseng pele ea tlhahiso le lisebelisoa tsa boleng bo holimo, 'me re laola ka thata sehokelo se seng le se seng ho tloha ho batching, ho theha, ho sintering ho isa litekong ho netefatsa hore sethala se seng le se seng sa kiln se fihlela litlhoko tsa boleng bo holimo. Re na le sehlopha sa litsebi tsa tekheniki se ka fanang ka tharollo ea sehlahisoa sa motho ka mong le tšehetso ea tekheniki ho latela maemo a ikhethileng a ts'ebetso le litlhoko tsa bareki ba fapaneng. Ka nako e ts'oanang, re thehile sistimi e ntle ea litšebeletso tsa kamora thekiso ho araba lipotso le litlhoko tsa bareki kapele le ho rarolla mathata ao bareki ba kopanang le ona nakong ea ts'ebeliso.

Haeba u batla lishelefo tse nang le ts'ebetso e phahameng, tsa bophelo bo bolelele bo phahameng ba mocheso o phahameng, u kanna ua khetha lishelefo tsa rona tsa silicon carbide kiln. Ba tla fana ka litiiso tse ka tšeptjoang bakeng sa tlhahiso ea hau ea indasteri ea mocheso o phahameng, ho u thusa ho ntlafatsa katleho ea tlhahiso le ho fokotsa litšenyehelo tsa tlhahiso. Rea u amohela ho ikopanya le rona ka nako efe kapa efe ho fumana tlhaiso-leseling e batsi ka sehlahisoa, ho ikopanya le mantsoe a qotsitsoeng, kapa ho etsa phapanyetsano ea tekheniki. Re labalabela ho sebelisana le uena ho theha bokamoso bo betere

Nako ea poso: Jul-16-2025