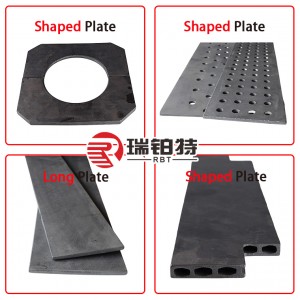

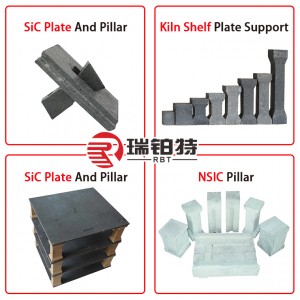

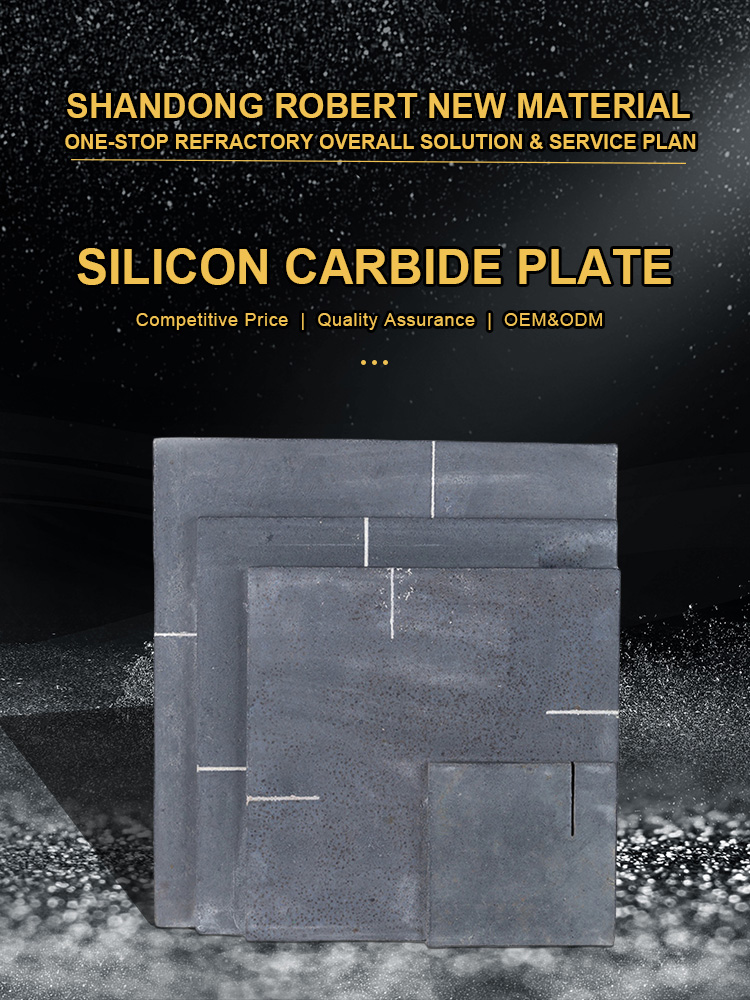

Lishelefo tsa Kiln tsa Sebōpeho se Ikhethileng sa Fektheri ea Pele Li-shelve tsa Kiln tse Kopantsoeng tsa Oxide le Silicon Carbide Sic Batts Plates

Lihlahisoa tsa rona li ananeloa haholo ebile lia tšepahala ke basebelisi 'me li tla khotsofatsa litlhoko tsa moruo le tsa sechaba tse fetohang khafetsa bakeng sa Lishelefo tsa Kiln tsa Original Custom Shape Refractory Kiln Shelves Oxide Bonded Silicon Carbide Sic Batts Plates, Bakeng sa mang kapa mang ea khahloang ke lintho life kapa life, etsa bonnete ba hore o ikutloa a lokolohile ho bua le rona bakeng sa lintlha tse ling kapa etsa bonnete ba hore o re romella lengolo-tsoibila hang-hang, re tla u araba ka mor'a lihora tse 24 'me khotheishene e sebetsang ka ho fetisisa e tla fanoa.

Lihlahisoa tsa rona li ananeloa haholo ebile lia tšepahala ke basebelisi 'me li tla khotsofatsa litlhoko tsa moruo le tsa sechaba tse fetohang khafetsa bakeng saPoleiti ea Sic Sheet le Silicon Carbide, re tšepa ka tieo ho theha kamano e ntle le ea nako e telele ea khoebo le k'hamphani ea hau e hlomphehang ka monyetla ona, o thehiloeng holim'a tekano, melemo ea bobeli le khoebo e putsang bohle ho tloha joale ho isa nakong e tlang. "Khotsofalo ea hau ke thabo ea rona".

Tlhahisoleseding ea Sehlahisoa

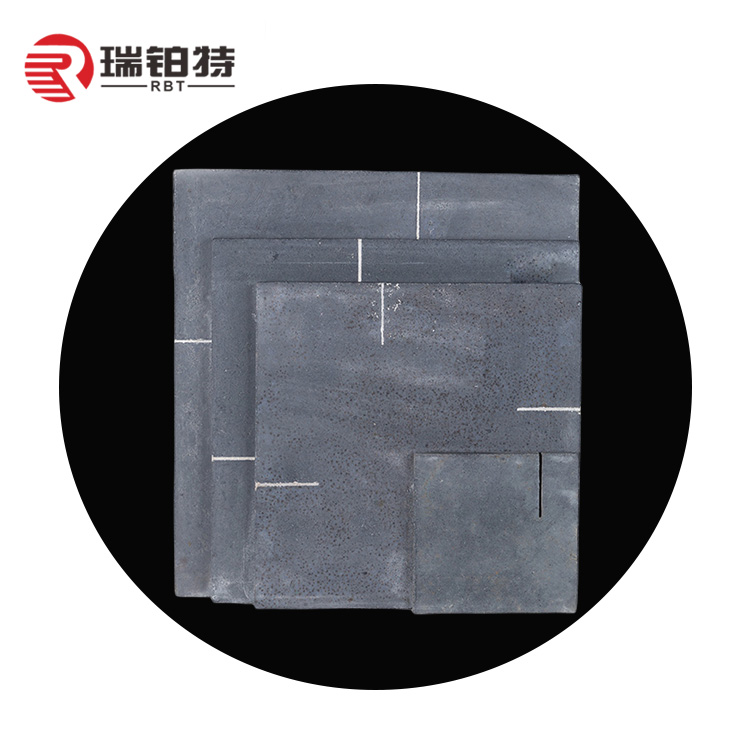

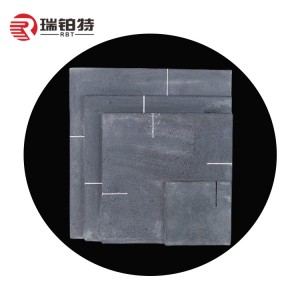

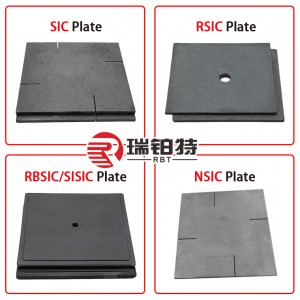

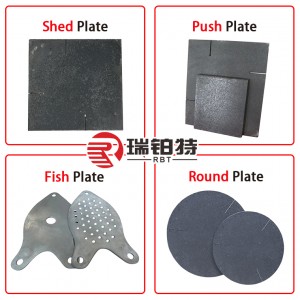

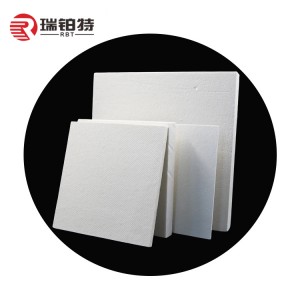

Lipoleiti tsa carbide tsa siliconLi entsoe ka silicon carbide ea boleng bo holimo e le thepa ea mantlha e tala, li eketsa lisebelisoa tse khethehileng tsa lik'hemik'hale tse tala e le li-binder, 'me li sebelisa lisebelisoa tse tsoetseng pele tsa ho bōpa li-hydraulic vibration ho etsa litlhaloso tse fapaneng le mehlala ea lisebelisoa tse hanyetsang mocheso o phahameng tse kang lipoleiti tsa shed, lipoleiti tsa push.

Mosebetsi oa matsoho:RBSiC(SiSiC)/SSiC/RSiC/SiC/NSiC

Likaroloana

1. Khanyetso e phahameng ea mocheso

2. Antioxidant e ntle

3. Khanyetso e ntle ea ts'enyeho

4. Ho hanyetsa ho tsofala hantle

5. Ho tsamaisa mocheso hantle

6. Bokgoni bo phahameng ba mocheso

Litšoantšo tse qaqileng

Lethathamo la Sehlahisoa

| Poleiti ea Ceramic ea Sintered SiC e se nang Khatello (SSIC) | |||

| Dikahare | Dikahare | ||

| Tahlehelo (850℃) | 0.33 | Botenya (g/cm3) | ≥3.1 |

| Al2O3 | <0.05 | Menyetla(%) | <0.1 |

| SiO2 | 0.25 | Mocheso o sebetsang (℃) | 1900 |

| F.Si | 0.07 | Bothata (HV0.5) | >2550 |

| SiC | ≥99.2 | Matla a ho Koba (Mpa) | 400-490 |

| TiO2 | 0.02 | Matla a Hanelang Khatello (Mpa) | >2500 |

| Fe2O3 | 0.07 | Modulus ea ho tenyetseha (Gpa) | ≥410 |

| CaO | 0.09 | Katoloso ea Thermal Coefficient (10 -6 / ℃) | 4.0 |

| MgO | 0.01 | Motlakase oa Thermal (W/mk) | 100-120 |

| K2O | 0.02 | Tlhahlobo ea Pono | Ho hloka Mapetso le Masoba |

| Na2O | 0.02 | Bophara | ≤±0.5mm |

Kopo

E ka sebelisoa ho sila phofo ka mefuta e fapaneng indastering ea tšepe, indastering ea lik'hemik'hale, khalaseng le masimong a mang, hammoho le ho tlosa metsi lik'hemik'haleng tsa ho qhibilihisa tšepe le tsa ho etsa pampiri, hammoho le likarolong tse fapaneng tsa ho khohlela.

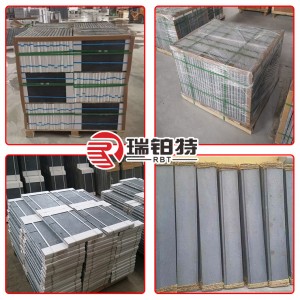

Sephutheloana le Ntlo ea polokelo

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e fumaneha Motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa e hanyetsang. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea ontong, theknoloji le thepa e hanyetsang kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a tekheniki a matla, boleng bo botle ba sehlahisoa le botumo bo botle.Feme ea rona e akaretsa lihekthere tse fetang 200 'me tlhahiso ea selemo le selemo ea thepa e bōpehileng joaloka refractory e ka ba lithane tse 30000 'me thepa e sa bōpehang joaloka refractory ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa e hanyetsang li kenyelletsa:thepa e hanyetsang alkaline; thepa e hanyetsang silicon ea aluminium; thepa e sa bōpehang e hanyetsang; thepa e thibelang mocheso e thibelang mocheso; thepa e khethehileng e thibelang; thepa e sebetsang e thibelang bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lihlahisoa tsa Robert li sebelisoa haholo liontong tse nang le mocheso o phahameng joalo ka litšepe tse se nang ferrous, tšepe, thepa ea kaho le kaho, lik'hemik'hale, motlakase, ho chesa litšila le kalafo ea litšila tse kotsi. Li boetse li sebelisoa lits'ebetsong tsa tšepe le tšepe tse kang li-ladle, EAF, liontong tsa blast, li-converter, liontong tsa coke, liontong tsa blast tse chesang; liontong tsa tšepe tse se nang ferrous tse kang li-reverberator, liontong tsa ho fokotsa, liontong tsa blast, le liontong tse potolohang; liontong tsa indasteri tsa thepa ea kaho tse kang liontong tsa khalase, liontong tsa samente le liontong tsa ceramic; liontong tse ling tse kang liboiler, li-incinerator tsa litšila, ontong ea ho besa, tse fihletseng litholoana tse ntle ts'ebelisong. Lihlahisoa tsa rona li romeloa Asia Boroa-bochabela, Asia Bohareng, Bochabela bo Hare, Afrika, Europe, Amerika le linaheng tse ling, 'me li thehile motheo o motle oa tšebelisano-'moho le likhoebo tse ngata tse tsebahalang tsa tšepe. Basebetsi bohle ba Robert ba labalabela ka tieo ho sebetsa le uena bakeng sa boemo ba ho hapa bohle.

Lipotso Tse Botsoang Khafetsa

Na u hloka thuso? Etsa bonnete ba hore u etela liforamo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Na u moetsi kapa mohoebi?

Re moetsi oa 'nete, fektheri ea rona e ikhethile ka ho hlahisa thepa e hanyetsang ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ea kamora thekiso.

U laola boleng ba hau joang?

Bakeng sa ts'ebetso e 'ngoe le e 'ngoe ea tlhahiso, RBT e na le sistimi e felletseng ea QC bakeng sa sebopeho sa lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa, 'me setifikeiti sa boleng se tla romelloa le thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Nako ea hau ea ho tlisa thepa ke efe?

Ho latela bongata, nako ea rona ea ho tlisa thepa e fapane. Empa re tšepisa ho e romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Na le fana ka disampole tsa mahala?

Ehlile, re fana ka disampole tsa mahala.

Na re ka etela k'hamphani ea hau?

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

MOQ bakeng sa odara ea teko ke eng?

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e ntle ka ho fetisisa ho latela boemo ba hau.

Hobaneng u re khetha?

Re ntse re etsa thepa e hanyetsang mocheso ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le boiphihlelo bo bongata, re ka thusa bareki ho rala li-kiln tse fapaneng le ho fana ka tšebeletso ea ho emisa hang feela.

Lihlahisoa tsa rona li ananeloa haholo ebile lia tšepahala ke basebelisi 'me li tla khotsofatsa litlhoko tsa moruo le tsa sechaba tse fetohang khafetsa bakeng sa Lishelefo tsa Kiln tsa Original Custom Shape Refractory Kiln Shelves Oxide Bonded Silicon Carbide Sic Batts Plates, Bakeng sa mang kapa mang ea khahloang ke lintho life kapa life, etsa bonnete ba hore o ikutloa a lokolohile ho bua le rona bakeng sa lintlha tse ling kapa etsa bonnete ba hore o re romella lengolo-tsoibila hang-hang, re tla u araba ka mor'a lihora tse 24 'me khotheishene e sebetsang ka ho fetisisa e tla fanoa.

Feme ea PelePoleiti ea Sic Sheet le Silicon Carbide, re tšepa ka tieo ho theha kamano e ntle le ea nako e telele ea khoebo le k'hamphani ea hau e hlomphehang ka monyetla ona, o thehiloeng holim'a tekano, melemo ea bobeli le khoebo e putsang bohle ho tloha joale ho isa nakong e tlang. "Khotsofalo ea hau ke thabo ea rona".