Ramming Mass

Tlhahisoleseding ya Sehlahiswa

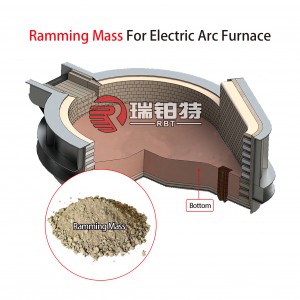

Ramming boimabua ka lisebelisoa tsa refractory tse sa bopehang tse hahiloeng ka ramming (manual kapa mechanical) le ho thatafatsoa ka tlas'a mocheso ka holimo ho mocheso o tloaelehileng. E entsoe ka ho kopanya li-refractory aggregates, powders, binders, admixtures le gradation e itseng le ho eketsa metsi kapa lino tse ling.

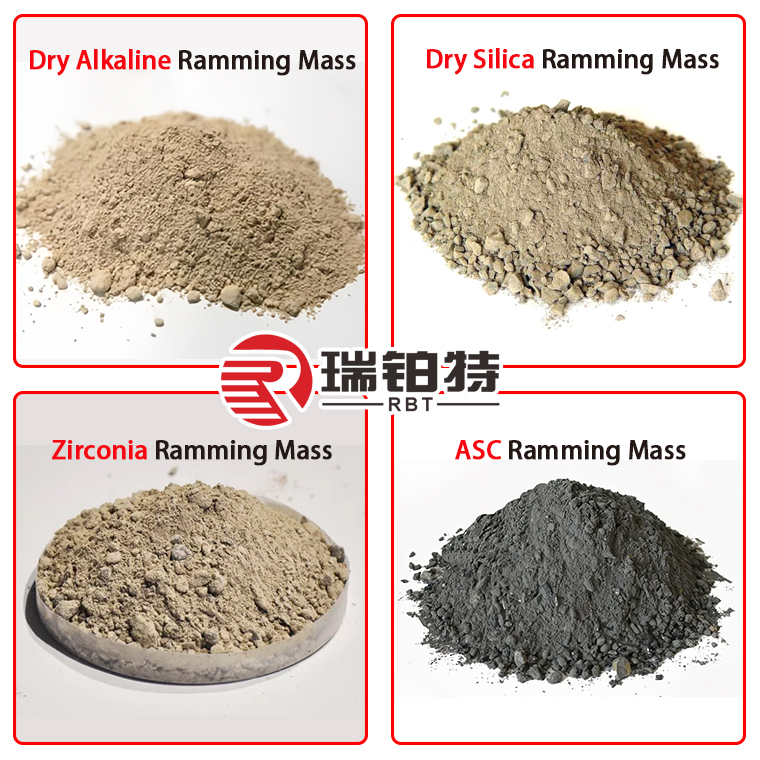

Karolelano ho ea ka Boitsebiso:Alumina e phahameng, letsopa, magnesia, dolomite, zirconium le silicon carbide-carbon refractory ramming mass.

Karolelano ho ea ka Mofuta oa Boitsebiso:Silika, corundum, magnesium, magnesia-calcium, magnesium-aluminium, magnesia-aluminium spinel le Al2O3 ~ SiC~C lisebelisoa tse omeletseng tse thothomelang.

Lintlha Litšoantšo

Index ea Lihlahisoa

| Phahameng Aluminium Ramming Mass | ||

| Ntho | RBTGM-1 | RBTGM-2 |

| Mocheso oa ho sebetsa(℃)≥ | 1750 | 1750 |

| Al2O3(%) ≥ | 85 | 89 |

| MgO(%) ≥ | 11 | 8 |

| Cr2O3(%) ≥ | 1.5 | 2 |

| Boima ba Bongata(g/cm3) ≥ | 3.1 | 3.15 |

| Sintering Mocheso(℃) ≥ | 1600 | 1650 |

| Silika Ramming Mass | |||

| Ntho | RBTGR-1 | RBTRG-2 | |

| Refractory(℃)≥ | 1600 | 1750 | |

| Karolo | SiO₂(%) | 98.5 | / |

| SiO₂+Cr2O3(%) | / | 99.3 | |

| Boima ba Bongata(g/cm3) ≥ | 2.1 | 2.3 | |

| Compressive Strength(MPa) | 11 | 15 | |

| Sintering Mocheso(℃) ≥ | 800 | 950 | |

| Boholo ba Karolo(mm) | 0-8 | 0-25 | |

| Magnesia Ramming Mass | ||||

| Ntho | RBTMR-1 | RBTMR-2 | RBTMR-3 | |

| Mocheso o Moholo (℃) | 1815 | 1815 | 1800 | |

| Karolo | MgO, % | 30.5 | 74.8 | 97 |

| Al2O3, % | 67.6 | 22.7 | / | |

| SiO2 ,% | 0.1 | 0.6 | 0.8 | |

| Boima ba Bongata(g/m3) | 3.08 | 2.98 | 3 | |

| Corundum Ramming Mass | ||

| Ntho | RBTGYRM-1 | RBTGYRM-2 |

| Mocheso oa ho sebetsa(℃)≥ | 1750 | 1750 |

| Al2O3(%) ≥ | 85 | 89 |

| MgO(%) ≥ | 11 | 8 |

| Cr2O3(%) ≥ | 1.5 | 2 |

| Boima ba Bongata(g/cm3) ≥ | 3.1 | 3.15 |

| Sintering Mocheso(℃) ≥ | 1600 | 1650 |

Kopo

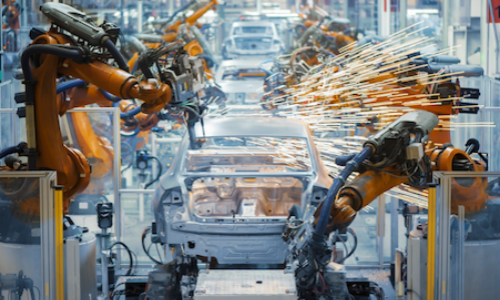

Metallurgy

Ho qhibiliha ha Metal e sa Feleng

Ramming boimae sebelisetsoa ho tlatsa lekhalo pakeng tsa lisebelisoa tse pholileng tsa sebōpi le masonry kapa thepa ea ho tlatsa bakeng sa lera la boemo ba masonry. Lisebelisoa tsa li-ramming li na le botsitso bo botle ba lik'hemik'hale, li hanana le khoholeho ea mobu, abrasion, spalling, le mocheso oa mocheso. Li sebelisoa haholo ho metallurgy, thepa ea kaho, ho qhibilihisa tšepe e seng ferrous, indasteri ea lik'hemik'hale, mechini le liindasteri tse ling tsa tlhahiso!

Mechini

Indasteri ea Lik'hemik'hale

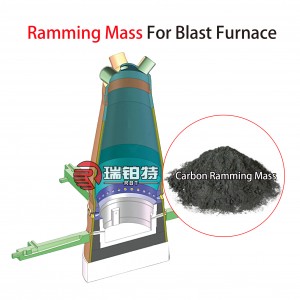

Kopo ea Ramming Mass ea Carbon

Pontšo ea Seboka

Sephutheloana le Bobolokelo

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e sebakeng sa Zibo City, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea lintho tse refractory. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea sebōpi, thekenoloji, le thepa ea ho rekisa kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a matla a tekheniki, boleng bo botle ba sehlahisoa le botumo bo botle. Feme ea rona e na le lihekthere tse fetang 200 mme tlhahiso ea selemo le selemo ea thepa e bōpehileng joaloka lithane tse ka bang 30000 'me thepa ea refractory e sa bopehang ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa ea refractory li kenyelletsa: lisebelisoa tsa alkaline refractory; lisebelisoa tsa aluminium silicon refractory; thepa e sa bōpehang refractory; lisebelisoa tse thibelang mocheso oa mocheso; thepa e khethehileng ea refractory; lisebelisoa tse sebetsang tsa refractory bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Hangata

U hloka thuso? Etsa bonnete ba hore u etela liforomo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, feme ea rona e khethehile ho hlahisa thepa ea refractory ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ka mor'a ho rekisa.

Bakeng sa ts'ebetso e 'ngoe le e' ngoe ea tlhahiso, RBT e na le tsamaiso e feletseng ea QC bakeng sa metsoako ea lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa,' me setifikeiti sa boleng se tla romelloa ka thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho itšetlehile ka bongata, nako ea rona ea ho fana e fapane. Empa re tšepisa ho romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ha e le hantle, re fana ka mehlala ea mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e molemohali ho latela boemo ba hau.

Re 'nile ra etsa thepa ea refractory ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le phihlelo e ruileng, re ka thusa bareki ho rala li-kilns tse fapaneng le ho fana ka ts'ebeletso e le 'ngoe.