E ka Lahleloa ka Refractory

Tlhaloso ea Sehlahisoa

Li-castle tse hanelang ho phatlohake motsoako oa li-aggregate tse hanyetsang, phofo le li-binder. Kamora ho eketsa metsi kapa lino tse ling, li loketse kaho ka mekhoa ea ho tšela le ho thothomela. Li ka boela tsa etsoa likarolo tse entsoeng esale pele tse nang le libopeho le boholo bo boletsoeng bakeng sa kaho ea li-lining tsa lifono tsa indasteri. E le ho ntlafatsa thepa ea 'mele le ea lik'hemik'hale le ts'ebetso ea kaho ea li-castable tse hanyetsang, hangata ho eketsoa metsoako e loketseng, joalo ka li-plasticizer, li-dispersant, li-accelerator, li-retarder, li-agent tsa katoloso, li-agent tsa debonding-gelling, jj. Ho phaella moo, bakeng sa li-castable tse hanyetsang tse sebelisoang libakeng tse nang le matla a maholo a mechini kapa thermal shock e matla, haeba ho eketsoa tekanyo e loketseng ea fiber ea tšepe e sa hloekang, ho tiea ha thepa ho tla eketseha haholo. Ho insulatory refractory castable, haeba likhoele tse sa pheleng li eketsoa, ha li khone ho ntlafatsa ho tiea feela, empa hape li ka thusa ho ntlafatsa thepa ea eona ea ho thibela mocheso. Kaha sebopeho sa mantlha sa thepa ea lintho tse ka sebelisoang ho lahla lintho tse sa sebetseng (tse kang li-aggregates le phofo, metsoako, li-binder le metsoako), mokhoa oa ho hoama le ho tiisa, mekhoa ea kaho, jj., li tšoana le konkreite boenjiniere ba sechaba, e kile ea bitsoakonkreite e hanyetsang.

Lethathamo la Sehlahisoa

| Lebitso la Sehlahisoa | E bobebe e ka lahleloa | ||||||

| Mocheso o Fokotsang ho Sebetsa | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110℃ Bongata ba Boima(g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Modulus ea ho Robeha (MPa) ≥ | 110℃×24h | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100℃×3h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400℃×3h | ― | ― | 3 | 10.8 | 8.1 | ||

| Matla a ho Silakanya a Batang (MPa) ≥ | 110℃×24h | 8 | 8 | 11 | 12 | 10 | |

| 1100℃×3h | 4 | 4 | 5 | 11 | 10 | ||

| 1400℃×3h | ― | ― | 15 | 22 | 14 | ||

| Phetoho e sa Feleng ea Linear (%) | 1100℃×3h | -0.65 1000℃×3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400℃×3h | ― | ― | -0.8 | -0.55 | -0.45 | ||

| Ho tsamaisa mocheso (Thermal Conductivity)W/mk) | 350℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| Al2O3(%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

| Lebitso la Sehlahisoa | E ka Lahleloa ka Samente e Tlase | |||||

| INDEX | RBTZJ-42 | RBTZJ-60 | RBTZJ-65 | RBTZJS-65 | RBTZJ-70 | |

| Mocheso o Fokotsang ho Sebetsa | 1300 | 1350 | 1400 | 1400 | 1450 | |

| Bongata ba Bongata (g/cm3) 110℃×24h≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Matla a ho Koba a Batang 110℃×24h(MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Matla a ho Silakanya a Batang (MPa) ≥ | 110℃×24h | 25 | 30 | 35 | 35 | 40 |

| CT℃×lihora tse 3 | 50 1300℃×3h | 55 1350℃×3h | 60 1400℃×3h | 40 1400℃×3h | 70 1400℃×3h | |

| Phetoho e sa Feleng ea Linear @CT℃ × 3h(%) | -0.5~+0.5 1300℃ | -0.5~+0.5 1350℃ | 0~+0.8 1400℃ | 0~+0.8 1400℃ | 0~+1.0 1400℃ | |

| Khanyetso ea Thermal Shock (Metsi a 1000℃) ≥ | ― | ― | ― | 20 | ― | |

| Al2O3(%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| CaO(%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| Fe2O3(%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Lebitso la Sehlahisoa | Matla a Phahameng a ka Lahleloa | |||||

| INDEX | HS-50 | HS-60 | HS-70 | HS-80 | HS-90 | |

| Mocheso o Fokotsang ho Sebetsa (℃) | 1400 | 1500 | 1600 | 1700 | 1800 | |

| 110℃ Bongata ba Boima(g/cm3) ≥ | 2.15 | 2.30 | 2.40 | 2.50 | 2.90 | |

| Modulus ea ho Rutture (MPa) ≥ | 110℃×24h | 6 | 8 | 8 | 8.5 | 10 |

| 1100℃×3h | 8 | 8.5 | 8.5 | 9 | 9.5 | |

| 1400℃×3h | 8.5 1300℃×3h | 9 | 9.5 | 10 | 15 | |

| Matla a ho Silakanya a Batang (MPa) ≥ | 110℃×24h | 35 | 40 | 40 | 45 | 60 |

| 1100℃×3h | 40 | 50 | 45 | 50 | 70 | |

| 1400℃×3h | 45 1300℃×3h | 55 | 50 | 55 | 100 | |

| Phetoho e sa Feleng ea Linear (%) | 1100℃×3h | -0.2 | -0.2 | -0.25 | -0.15 | -0.1 |

| 1400℃×3h | -0.45 1300℃×3h | -0.4 | -0.3 | -0.3 | -0.1 | |

| Al2O3(%) ≥ | 48 | 48 | 55 | 65 | 75 | 90 |

| CaO(%) ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Fe2O3(%) ≤ | 3.5 | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 |

Kopo

1. E ka lahleloa ka aluminium e phahameng:Sesebelisoa sa ho lahla sa aluminium e phahameng se entsoe haholo-holo ka alumina (Al2O3) 'me se na le ho hanyetsa ho hoholo, ho hanyetsa slag le ho hanyetsa ho thothomela ha mocheso. Se sebelisoa haholo liontong le liforong tsa mocheso o phahameng ka har'a tšepe, litšepe tse se nang ferrous, lik'hemik'hale le liindasteri tse ling.

2. Tšepe e matlafalitsoeng e ka lahleloa ka tšepe:Setlolo se matlafalitsoeng sa tšepe se thehilwe hodima di-castable tse tlwaelehileng mme di-fiber tsa tshepe di a eketswa ho eketsa kganyetso ya sona ya mocheso, kganyetso ya ho tsofala le kganyetso ya slag. Se sebediswa haholoholo diontong, dibotong tsa ontong le dikarolong tse ding indastering ya tshepe, metallurgy, petrochemical le tse ding.

3. E ka lahleloa ka bongata:Sesebelisoa sa ho lahla sa Mullite se entsoe haholo-holo ka mullite (MgO·SiO2) 'me se na le khanyetso e ntle ea ho tsofala, ho hanyetsa le ho hanyetsa slag. Hangata se sebelisoa likarolong tsa bohlokoa tse kang liontong tsa ho etsa tšepe le li-converter indastering ea tšepe, ea tšepe le ea tse ling.

4. Silicon carbide e ka lahleloa:Silicon carbide castable e entsoe haholo-holo ka silicon carbide (SiC) 'me e na le khanyetso e ntle ea ho tsofala, khanyetso ea slag le khanyetso ea mocheso. E sebelisoa haholo liontong tsa mocheso o phahameng, libetheng tsa ontong le likarolong tse ling tsa litšepe tse se nang ferrous, lik'hemik'hale, liserami le liindasteri tse ling.

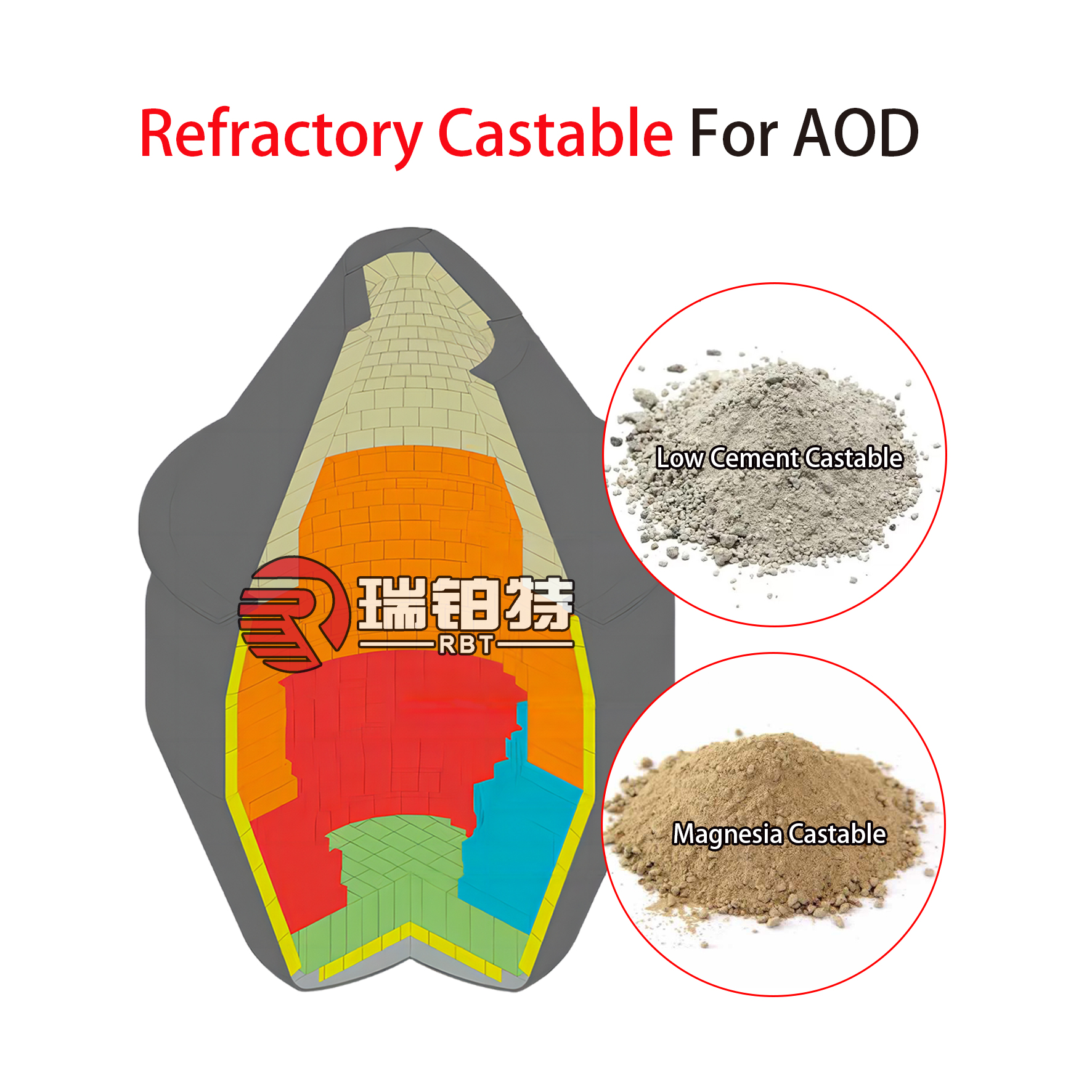

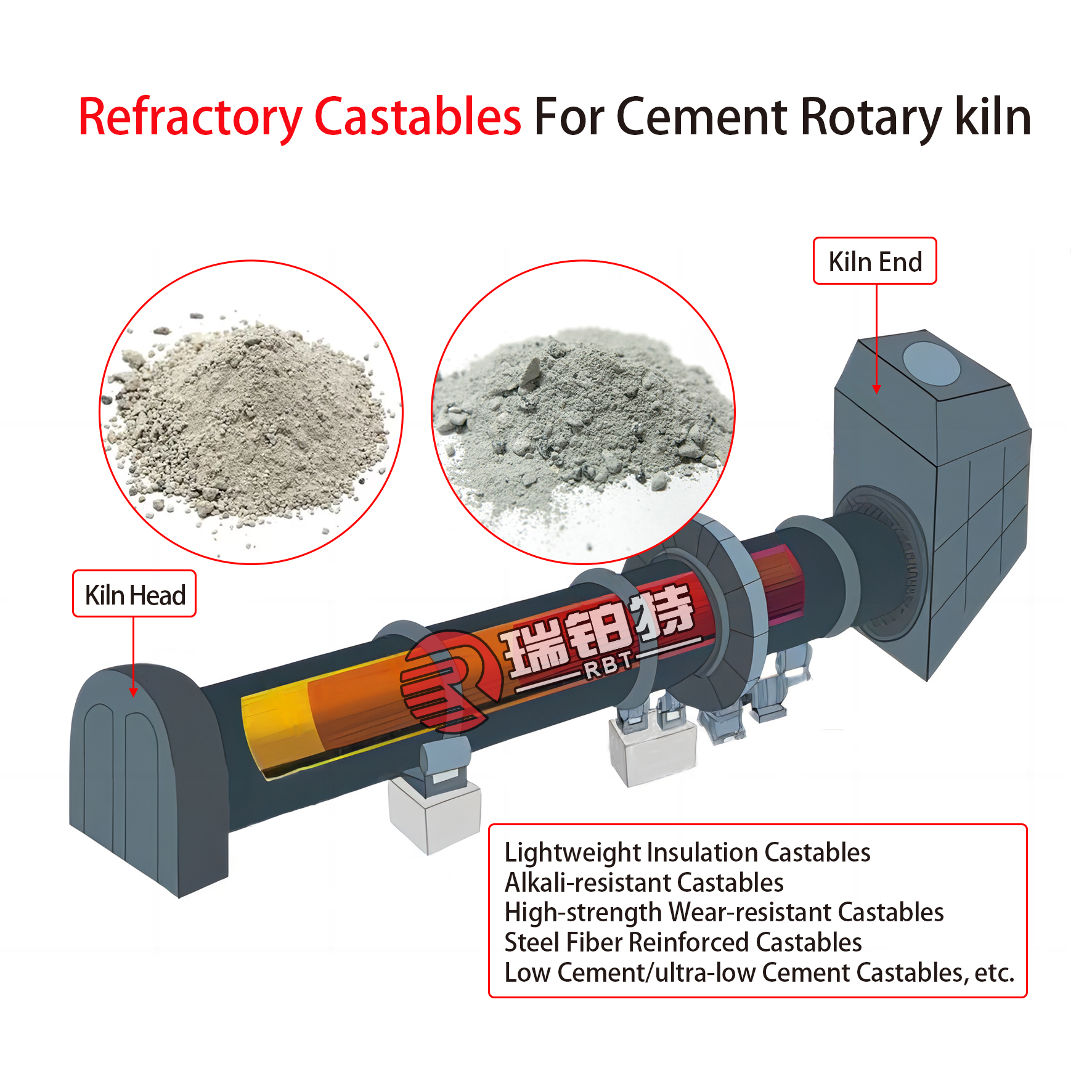

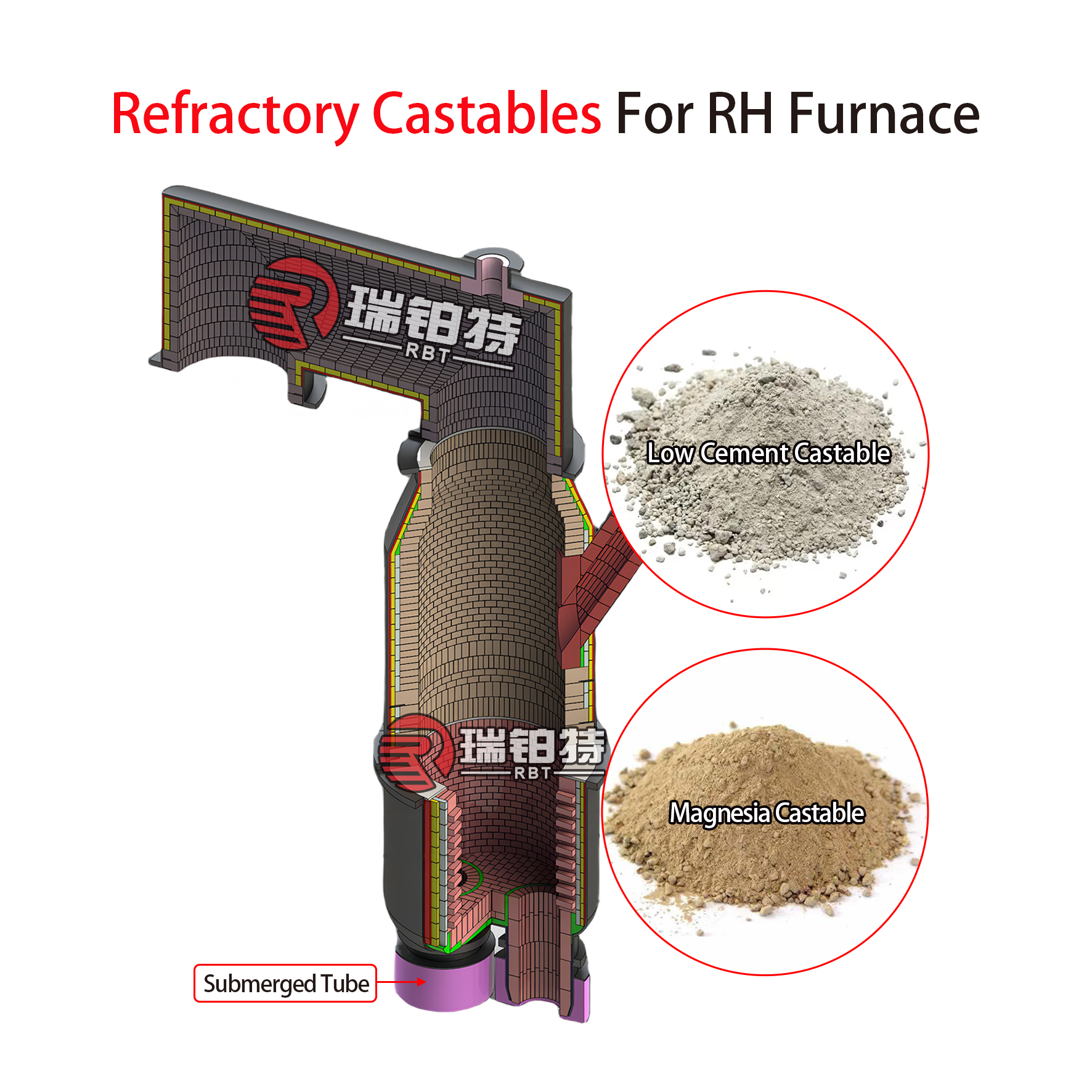

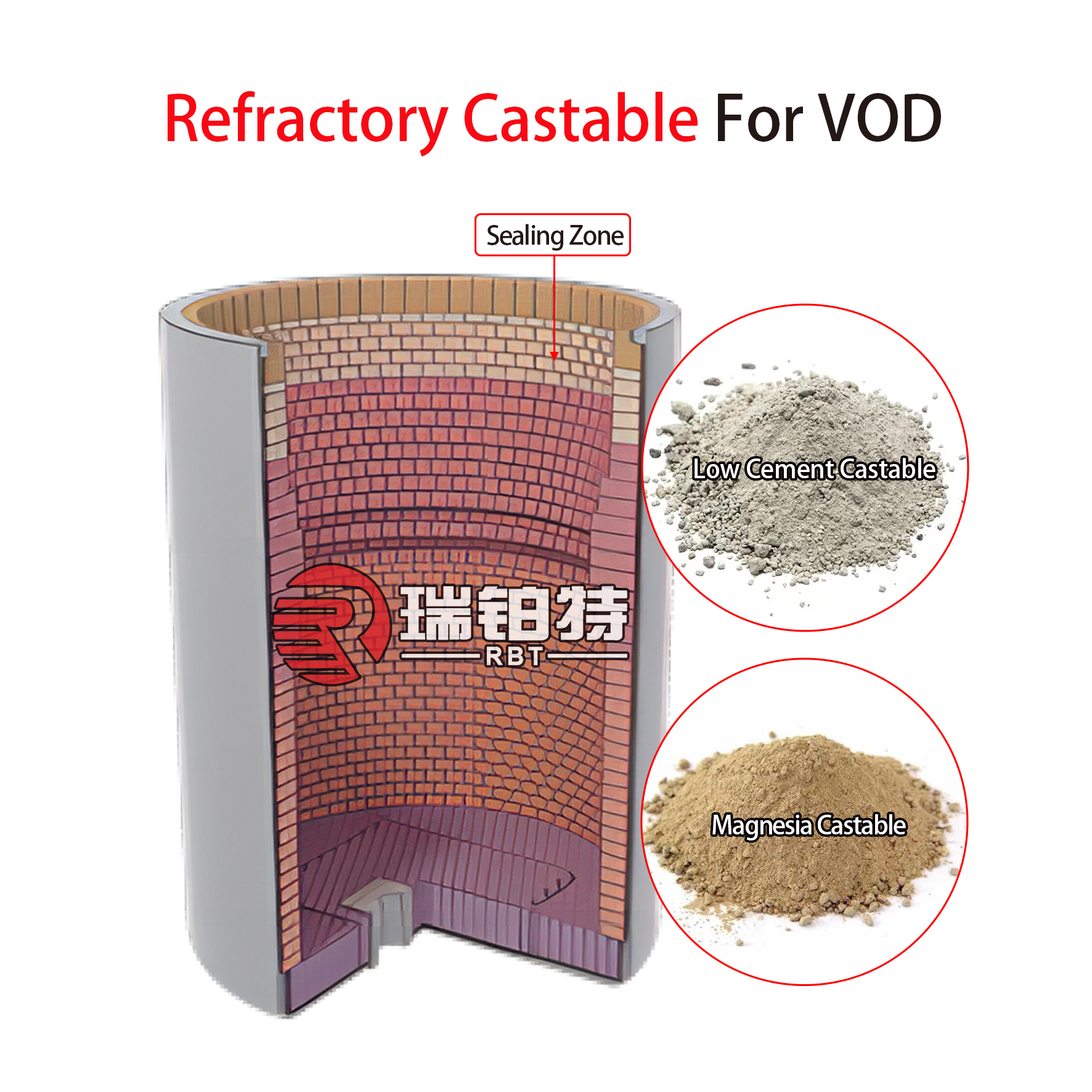

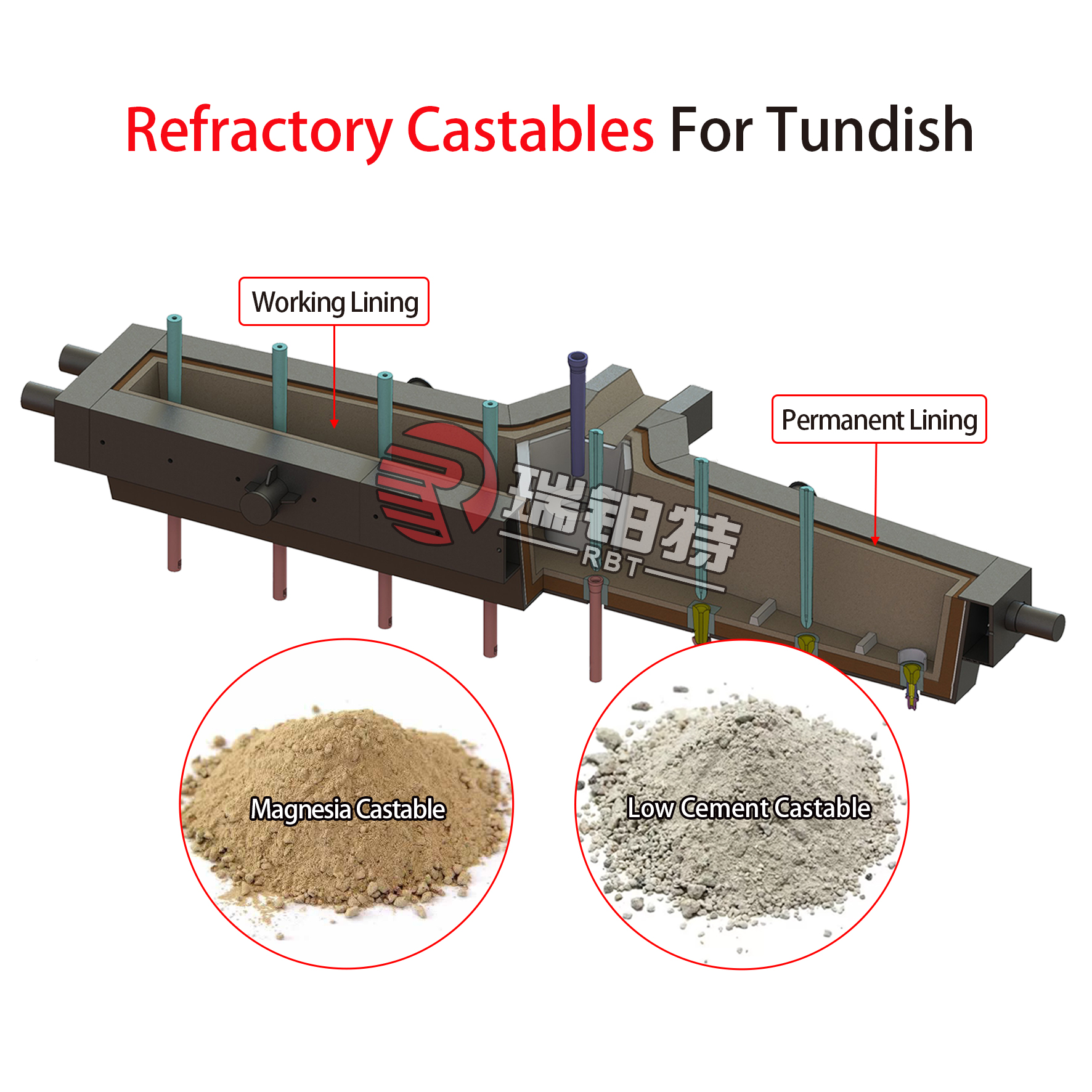

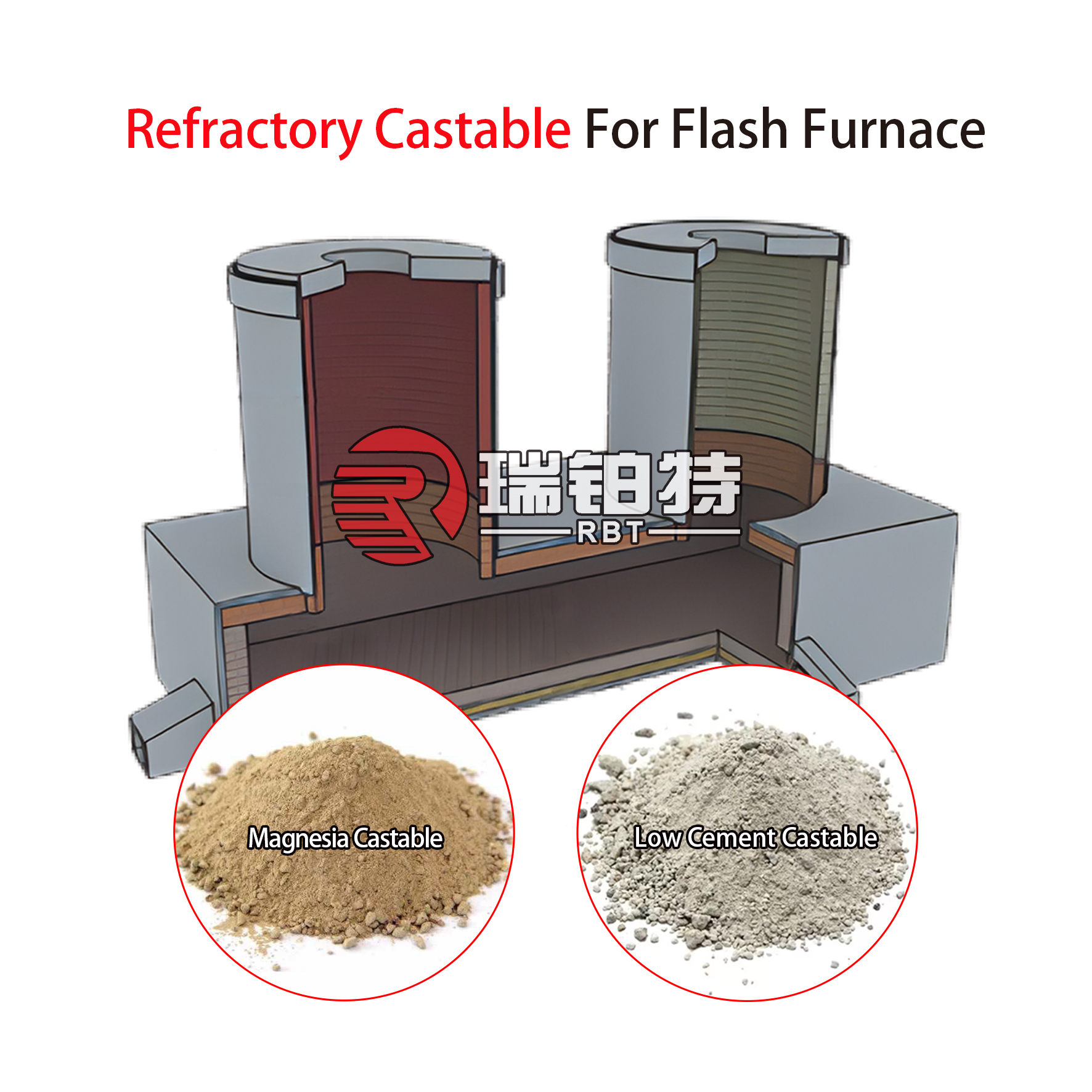

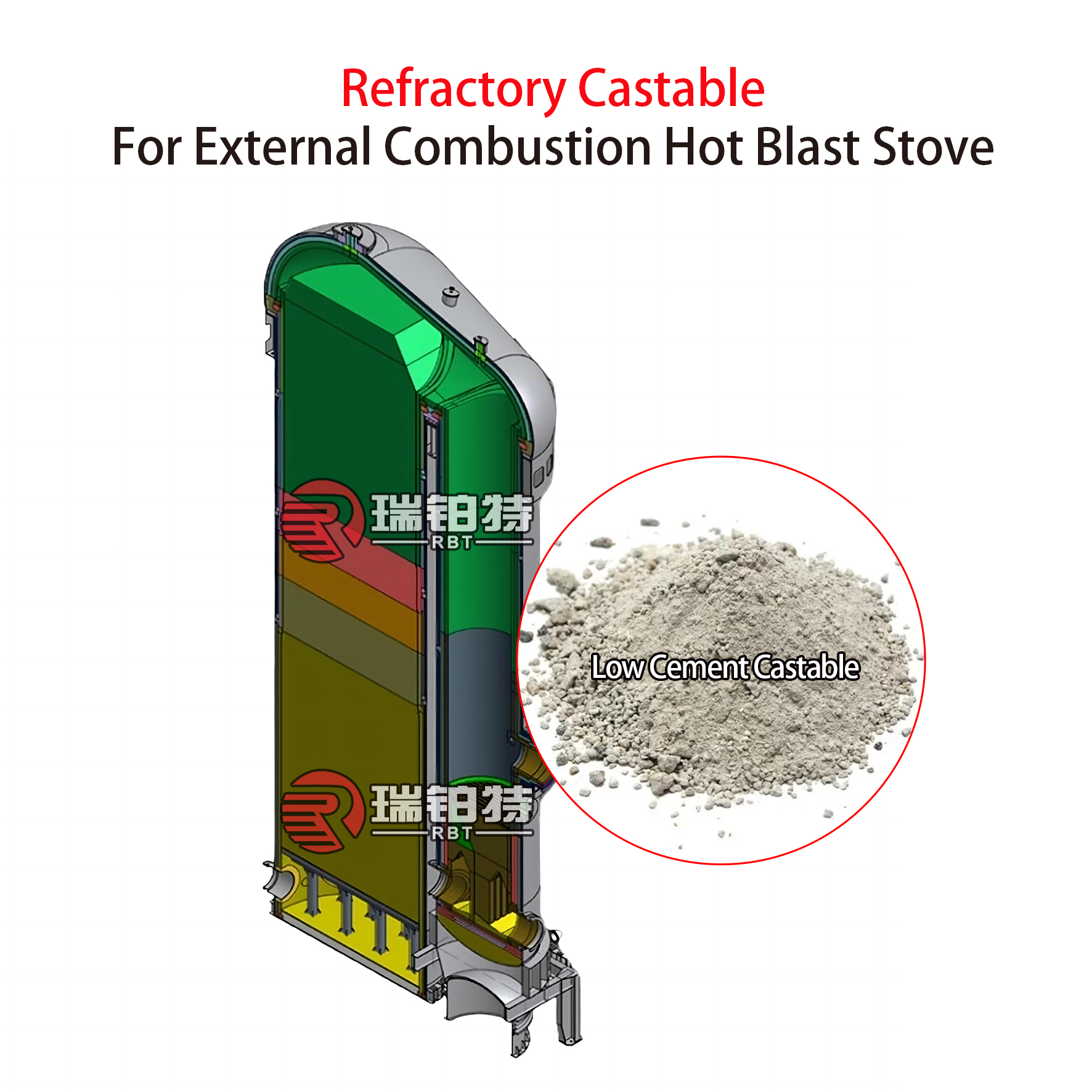

5. Disebediswa tse ka lahlelwang tse se nang samente e ngata:e bua ka di-castable tse nang le samente e tlase, e leng hoo e ka bang 5%, mme tse ding di bile di fokotswa ho 1% ho isa ho 2%. Di-castable tse nang le samente e tlase di sebedisa dikarolwana tse ntle haholo tse sa feteng 1μm, mme kganyetso ya tsona ya mocheso, kganyetso ya slag le kganyetso ya kgoholeho ya mobu di ntlafaditswe haholo. Di-castable tse nang le samente e tlase di loketse di-linings tsa dionto tse fapaneng tsa kalafo ya mocheso, dionto tsa ho futhumatsa, di-kiln tse otlolohileng, di-kiln tse potolohang, dikoahelo tsa onto ya motlakase, masoba a ho tapa a onto ya ho phatloha, jj.; di-castable tse nang le samente e tlase tse ikemelang di loketse di-linings tsa sethunya sa spray bakeng sa metallurgy ya spray, di-linings tse hanelang ho robeha mochesong o phahameng bakeng sa di-reactor tsa petrochemical catalytic cracking, le di-linings tse ka ntle tsa diphaephe tsa ho phodisa metsi a onto ya ho futhumatsa.

6. Li-castable tse hanyetsanang le ho tsofala tse sa tsofaleng:Likarolo tse ka sehloohong tsa li-castable tse hanyetsang ho tsofala li kenyelletsa li-aggregates tse hanyetsang, phofo, li-additives le li-binder. Li-castable tse thibelang ho tsofala ke mofuta oa thepa e sa fetoheng e sebelisoang haholo indastering ea tšepe, lik'hemik'hale tsa peterole, thepa ea kaho, motlakase le liindasteri tse ling. Thepa ena e na le melemo ea ho hanyetsa mocheso o phahameng, ho hanyetsa ho tsofala le ho hanyetsa khoholeho ea mobu. E sebelisoa ho lokisa le ho sireletsa lesela la lisebelisoa tse futhumatsang mocheso o phahameng tse kang lionto le li-boiler ho eketsa bophelo ba ts'ebeletso ea lisebelisoa.

7. Lebese le ka lahleloa:Ladle castable ke castable e sa fetoheng e entsoeng ka clinker ea boleng bo holimo ea alumina bauxite le silicon carbide e le thepa ea mantlha, e nang le sehokelo sa samente sa aluminate se hloekileng, se qhalanyang, sesebelisoa se thibelang ho honyela, coagulant, faeba e sa phatloheng le lintho tse ling tse tlatsetsang. Hobane e na le phello e ntle lera le sebetsang la ladle, e boetse e bitsoa aluminium silicon carbide castable.

8. E bobebe e thibelang ho ruruha e ka lahleloa e sa thibeleng ho ruruha:Sesebelisoa se bobebe sa ho thibela ho ruruha se thibelang ho ruruha ke sesebelisoa se thibelang ho ruruha se nang le boima bo bobebe, matla a phahameng le ts'ebetso e ntle ea ho thibela ho futhumatsa. Haholo-holo se entsoe ka lihlopha tse bobebe (tse kang perlite, vermiculite, jj.), thepa e tsitsitseng mochesong o phahameng, li-binder le li-additives. E sebelisoa haholo lisebelisoa tse fapaneng tsa indasteri tse futhumatsang hodimo, tse kang liontong tsa indasteri, liontong tsa kalafo ea mocheso, liontong tsa tšepe, liontong tse qhibilihang tsa khalase, jj., ho ntlafatsa ts'ebeliso e ntle ea matla ea lisebelisoa le ho fokotsa tšebeliso ea matla.

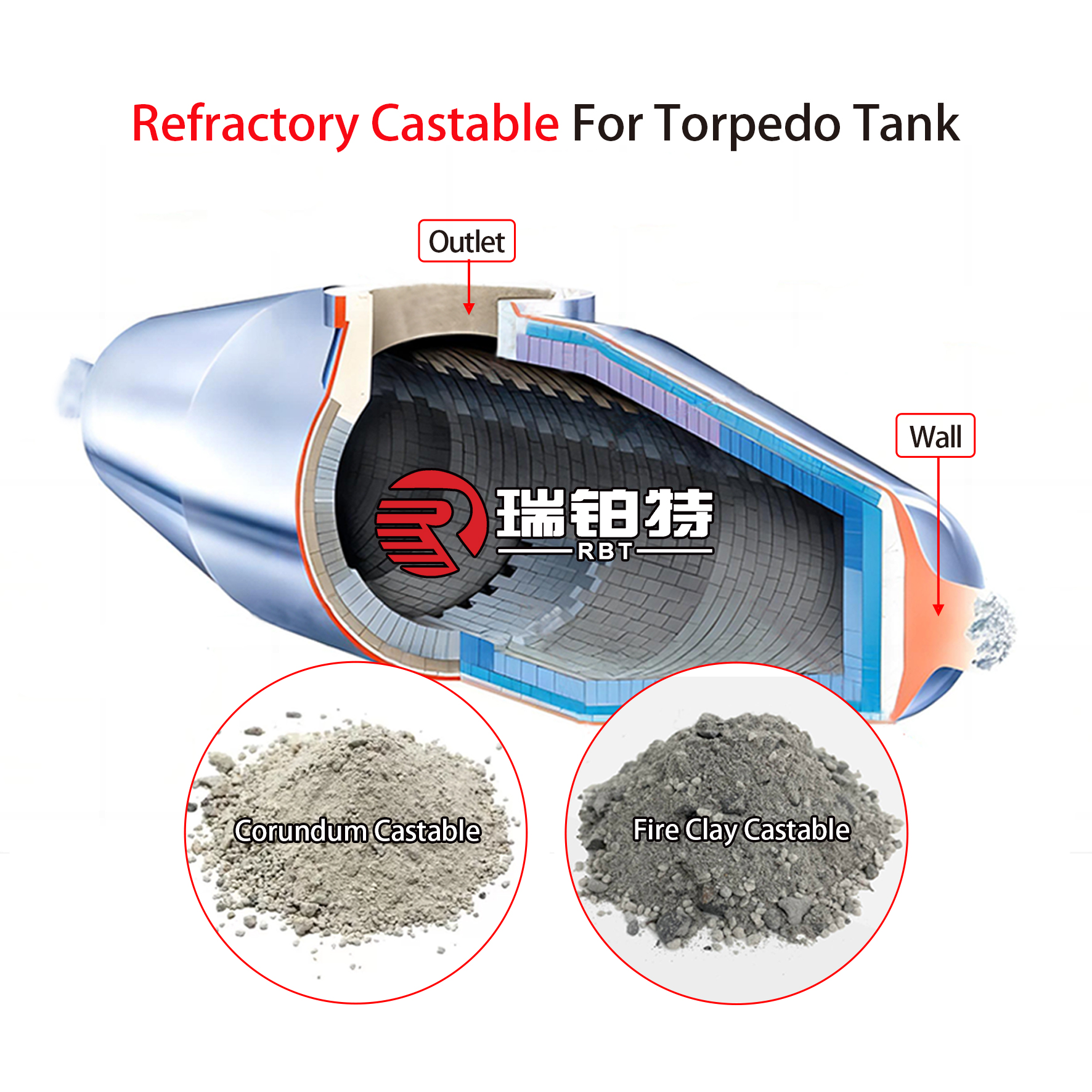

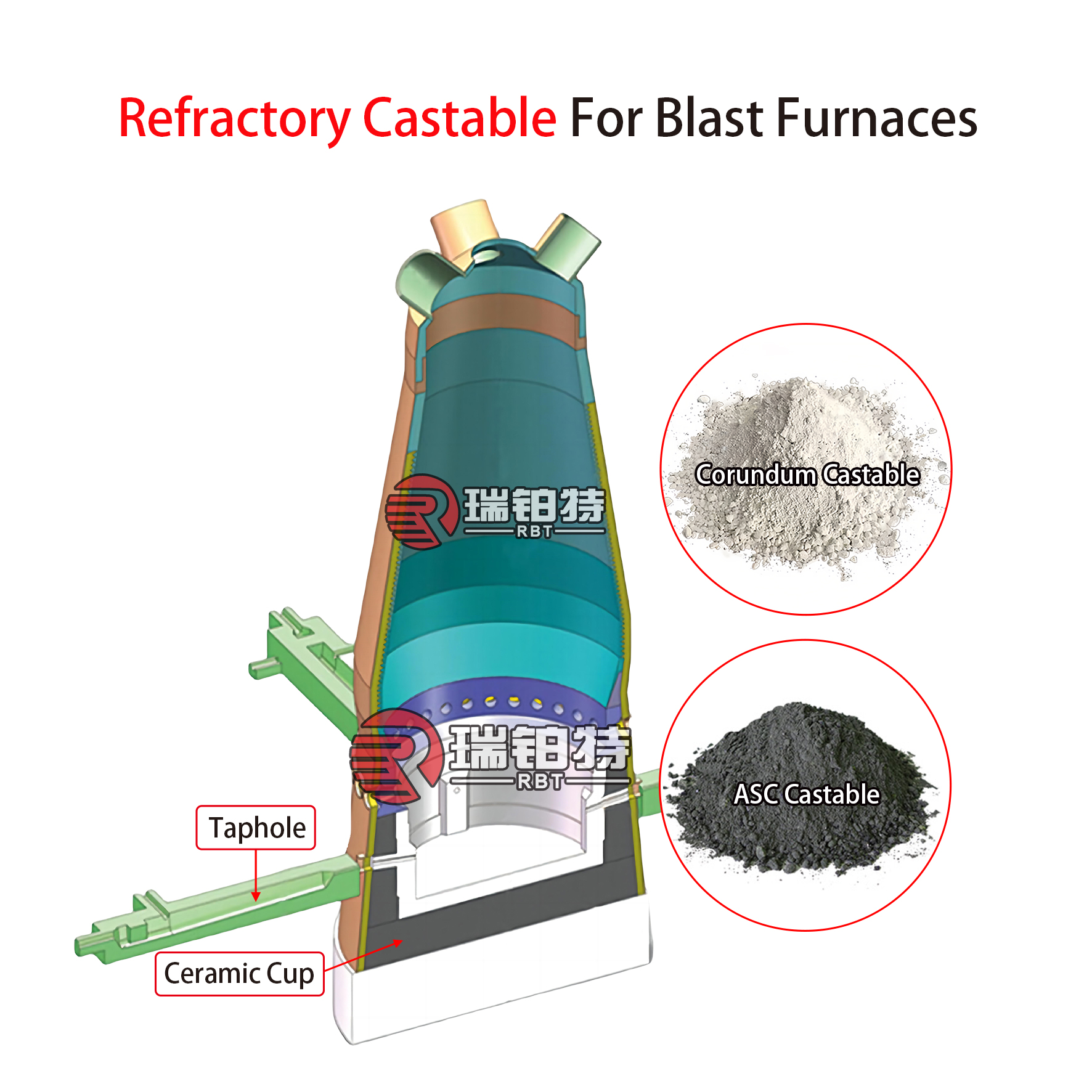

9. Corundum e ka lahleloa:Ka ts'ebetso ea eona e ntle haholo, corundum castable e fetohile khetho e ntle bakeng sa likarolo tsa bohlokoa tsa lionto tsa mocheso. Litšobotsi tsa corundum castable ke matla a phahameng, mocheso o nolofatsang mojaro o phahameng le ho hanyetsa slag hantle, jj. Mocheso o sebelisoang ka kakaretso ke 1500-1800℃.

10. Magnesium e ka lahleloa:Haholo-holo e sebelisoa lisebelisoa tsa mocheso o phahameng, e na le khanyetso e ntle khahlanong le ho bola ha alkaline slag, index e tlase ea oksijene 'me ha e na tšilafalo khahlanong le tšepe e qhibilihisitsoeng. Ka hona, e na le menyetla e mengata ea ts'ebeliso indastering ea tšepe, haholo-holo tlhahisong ea tšepe e hloekileng le indastering ea thepa ea kaho.

11. Letsopa le ka lahleloa:Likarolo tse ka sehloohong ke letsopa le clinker le letsopa le kopantsoeng, le nang le botsitso bo botle ba mocheso le ho se fetohe ha mocheso ka tsela e itseng, 'me theko e tlase haholo. Hangata e sebelisoa ka har'a lesela la lionto tse akaretsang tsa indasteri, joalo ka lionto tse futhumatsang, lionto tse futhumatsang, liboiler, jj. E ka mamella mocheso o itseng oa mojaro oa mocheso 'me ea bapala karolo ho thibeleng mocheso le ho sireletsa' mele oa sebopi.

12. Li-castable tse ommeng:Disebediswa tse ommeng tse ka lahlelwang di entswe haholo-holo ka di-aggregate tse hanyetsang, phofo, di-binder le metsi. Metswako e tlwaelehileng e kenyeletsa letsopa la clinker, tertiary alumina clinker, phofo e ntle haholo, samente ya CA-50, dispersants le di-agent tse kenelletseng tsa siliceous kapa feldspar.

Di-castable tse ommeng di ka arolwa ka mefuta e mengata ho latela tshebediso le metswako ya tsona. Mohlala, di-castable tse ommeng tse kenelletseng di sebediswa haholoholo diseleng tsa aluminium electrolytic, tse ka thibelang ho kenella ha di-electrolyte ka katleho le ho atolosa bophelo ba tshebeletso ya disele. Ho feta moo, di-castable tse ommeng tse hanelang di loketse di-hardware, ho qhibilihisa, indasteri ya dikhemikhale, ditshipi tse seng tsa ferrous le diindasteri tse ding, haholoholo indastering ya tshepe, tse kang molomo wa ontong o ka pele wa ontong, ontong e qhalanang, sekoahelo sa hlooho ya ontong le dikarolo tse ding.

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd. e fumaneha Motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa e hanyetsang. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea ontong, theknoloji le thepa e hanyetsang kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a tekheniki a matla, boleng bo botle ba sehlahisoa le botumo bo botle.Feme ea rona e akaretsa lihekthere tse fetang 200 'me tlhahiso ea selemo le selemo ea thepa e bōpehileng joaloka refractory e ka ba lithane tse 30000 'me thepa e sa bōpehang joaloka refractory ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa e hanyetsang li kenyelletsa:thepa e hanyetsang alkaline; thepa e hanyetsang silicon ea aluminium; thepa e sa bōpehang e hanyetsang; thepa e thibelang mocheso e thibelang mocheso; thepa e khethehileng e thibelang; thepa e sebetsang e thibelang bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lihlahisoa tsa Robert li sebelisoa haholo liontong tse nang le mocheso o phahameng joalo ka litšepe tse se nang ferrous, tšepe, thepa ea kaho le kaho, lik'hemik'hale, motlakase, ho chesa litšila le kalafo ea litšila tse kotsi. Li boetse li sebelisoa lits'ebetsong tsa tšepe le tšepe tse kang li-ladle, EAF, liontong tsa blast, li-converter, liontong tsa coke, liontong tsa blast tse chesang; liontong tsa tšepe tse se nang ferrous tse kang li-reverberator, liontong tsa ho fokotsa, liontong tsa blast, le liontong tse potolohang; liontong tsa indasteri tsa thepa ea kaho tse kang liontong tsa khalase, liontong tsa samente le liontong tsa ceramic; liontong tse ling tse kang liboiler, li-incinerator tsa litšila, ontong ea ho besa, tse fihletseng litholoana tse ntle ts'ebelisong. Lihlahisoa tsa rona li romeloa Asia Boroa-bochabela, Asia Bohareng, Bochabela bo Hare, Afrika, Europe, Amerika le linaheng tse ling, 'me li thehile motheo o motle oa tšebelisano-'moho le likhoebo tse ngata tse tsebahalang tsa tšepe. Basebetsi bohle ba Robert ba labalabela ka tieo ho sebetsa le uena bakeng sa boemo ba ho hapa bohle.

Lipotso Tse Botsoang Khafetsa

Na u hloka thuso? Etsa bonnete ba hore u etela liforamo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, fektheri ea rona e ikhethile ka ho hlahisa thepa e hanyetsang ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ea kamora thekiso.

Bakeng sa ts'ebetso e 'ngoe le e 'ngoe ea tlhahiso, RBT e na le sistimi e felletseng ea QC bakeng sa sebopeho sa lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa, 'me setifikeiti sa boleng se tla romelloa le thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho latela bongata, nako ea rona ea ho tlisa thepa e fapane. Empa re tšepisa ho e romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ehlile, re fana ka disampole tsa mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e ntle ka ho fetisisa ho latela boemo ba hau.

Re ntse re etsa thepa e hanyetsang mocheso ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le boiphihlelo bo bongata, re ka thusa bareki ho rala li-kiln tse fapaneng le ho fana ka tšebeletso ea ho emisa hang feela.