Sepeipi sa Tšireletso sa RSiC

Tlhahisoleseding ea Sehlahisoa

Liphaephe tsa Tšireletso ea Carbide ea Siliconke dikarolo tse ikgethang tsa tubula tse entsweng ka thepa ya ceramic ya silicon carbide (SiC), tse sebediswang haholoholo ho sireletsa dikarolo tse bonolo (tse kang di-thermocouple) kapa e le dikarolo tsa mantlha disebedisweng tsa ho tsamaisa mokelikeli o mocheso o phahameng le phapanyetsano ya mocheso.

Lihlahisoa tsa rona li etsoa haholo-holo ka ho sebelisa mekhoa e meraro:Ho sintering ha karabelo (RBSiC), Recrystallization (RSiC), Silicon nitride e tlamiloeng ka silicon carbide (NSiC)

1. Liphaephe tsa tšireletso tsa RSiC

Ka ho sebedisa phofo e nyane ya SiC e hlwekileng haholo e le thepa e tala, e silwa mochesong o phahameng (2000–2200℃). Sebopeho se teteaneng se thehwa ka ho kopanngwa ha di-crystallization le moedi wa dithollo wa dikarolwana tsa SiC ka botsona, ntle le mohato o eketsehileng wa ho kopanya.

Litšobotsi tsa Bohlokoa:

Khanyetso e Ikhethang ea Mocheso o Phahameng:Mocheso oa ts'ebetso oa nako e telele ho fihlela ho 1600℃, khanyetso ea nako e khuts'oane ho 1800℃, e leng se etsang hore e be e ntle ka ho fetisisa mabapi le khanyetso ea mocheso o phahameng har'a mefuta e meraro, e loketseng li-oven tsa mocheso o phahameng haholo (joalo ka li-oven tsa sintering tsa ceramic le li-oven tsa metallurgical blast).

Khanyetso e Hlollang ea Oxidation:Maemong a mocheso o phahameng, filimi e teteaneng e sireletsang SiO₂ e thehoa holim'a metsi, e thibela ho kenella ho eketsehileng ha SiC ea ka hare, e bonts'a botsitso bo phahameng haholo sepakapakeng se eketsang oxidizing.

Katoloso ea Thermal e Tlase Haholo:Koefficient ea katoloso ea mocheso ke 4.5 × 10⁻⁶ /℃ feela, e fanang ka khanyetso e ntle ea ho thothomela ha mocheso, leha e le tlase hanyane ho feta ea carbide ea silicon e kopantsoeng le nitride.

Ho thatafala ho hoholo le ho hanyetsa ho tsofala ho hoholo:Ka boima ba Mohs bo haufi le 9, e bonahatsa khanyetso e ikhethang khahlanong le khoholeho ea thepa le ho hohlana, e leng se etsang hore e lokele maemo a moea o phallang mochesong o phahameng le a phallo ea metsi a nang le likaroloana tse tiileng.

Ho tsitsa ha lik'hemik'hale ho matla:E hanela li-acid tse matla le li-alkali, 'me ha e arabele le boholo ba litšepe tse qhibilihisitsoeng.

Meeli:

Mocheso o phahameng haholo oa ho chesa, o fellang ka masoba a manyane a phahameng (hoo e ka bang 5%–8%) le khanyetso e phahameng e fokolang hanyane; ho tetebela ha mocheso oa kamore ho phahameng haholo, le khanyetso ea tšusumetso ha li ntle joalo ka silicon carbide e kopantsoeng le silicon nitride.

2. Liphaephe tsa tšireletso ea RBSiC

Ka ho sebedisa dikarolwana tsa SiC le graphite e le thepa e tala, thepa e feta tshebetsong ya ho kenella ha silicon. Silicon e metsi e kenella le ho tlatsa masoba, e arabela le graphite ho theha mohato o motjha wa SiC, qetellong e bopa sebopeho se kopaneng sa "SiC framework + free silicon".

Litšobotsi tsa Bohlokoa:

Sekhahla se phahameng le masoba a tlase:Silicone e sa lefelloeng e tlatsa masoba, e fokotsa masoba ho fihlela ka tlase ho 1%, e leng se fellang ka ho se kene hantle ha moea le ho hanyetsa khatello e phahameng, e loketseng khatello e phahameng le mocheso o phahameng.

maemo a ho kwala (jwalo ka dionto tse futhumatsang kgatello).

Litšobotsi tse ntle tsa mechini:Matla a ho kokomoha ha mocheso wa kamore ke 250–400MPa, ho tiea ha ho robeha ho hoholo, le ho hanyetsa ho matla ho feta silicon carbide e ntjhafaditsweng.

Khanyetso e itekanetseng ea mocheso o phahameng:Mocheso oa ts'ebetso oa nako e telele ke 1200℃. Ka holimo ho 1350℃, silicon e lokolohileng ea nolofala, e leng se lebisang ho fokotseheng ha matla le ho fokotsa ts'ebetso ea mocheso o phahameng.

Ho sebetsa hantle:Boteng ba silicon e lokolohileng bo fokotsa ho robeha ha thepa, e leng se etsang hore ho be bonolo ho e kenya ka dibopeho tse rarahaneng, e leng se fellang ka ditjeo tse tlase tsa tlhahiso.

Meeli:

Tshebetso ya mocheso o phahameng e lekanyetswa ke silicon e lokolohileng, e leng se etsang hore e se ke ya lokela ho sebediswa nako e telele ho feta 1350℃; silicon e lokolohileng e arabela habonolo le di-alkali tse matla, aluminium e qhibilihisitsweng, jj., e leng se fellang ka sebaka se sesesaane sa ho hanyetsa mafome.

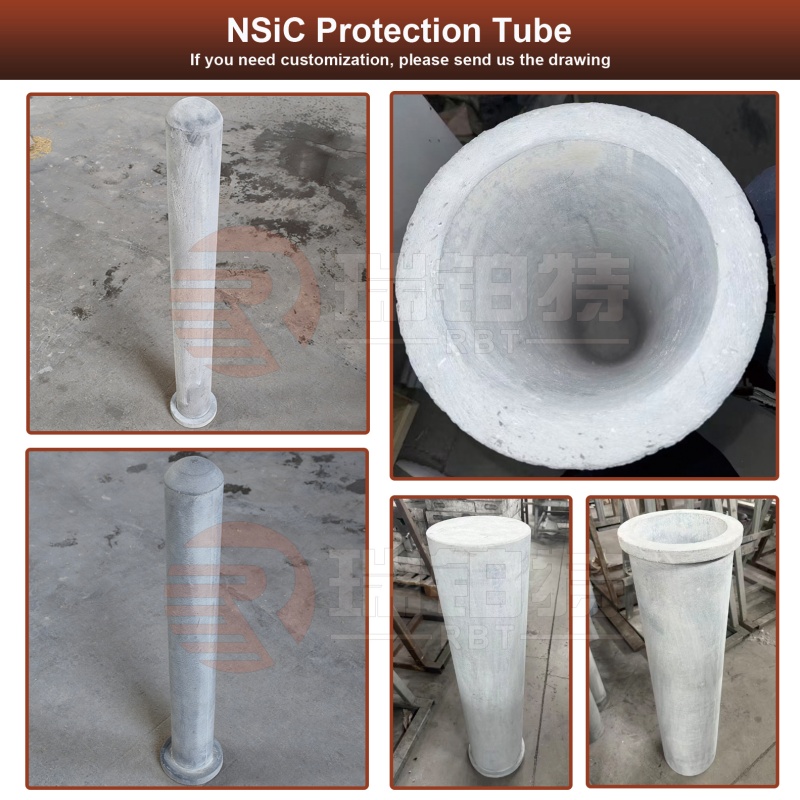

3. Phaephe ea tšireletso ea NSiSC

Ke thepa e kopaneng e entsoeng ka ho hokahanya likaroloana tsa SiC ka thata ka har'a matrix ea silicon carbide ka ho hlahisa Si₃N₄ e le mohato o tlamang ka karabelo ea nitriding.

Likarolo tsa Bohlokoa:

1. Khanyetso ea ho Tšoha ha Thermal e Phahameng ka ho Fetisisa:Koefficient e tlase ea katoloso ea mocheso le ho tiea ho hoholo ha karolo e kopantsoeng ea Si₃N₄ ho lumella tube e sireletsang ho mamella ho futhumala le ho pholisa ka potlako ho feta 1000℃ ntle le ho petsoha ka lebaka la liphetoho tsa tšohanyetso tsa mocheso, e leng se etsang hore e lokele maemo a ts'ebetso a nang le ho feto-fetoha ha mocheso khafetsa.

2. Khanyetso e Hlollang ea Ts'enyeho:E tsitsitse haholo khahlanong le li-acid tse matla, li-alkali tse matla, litšepe tse qhibilihisitsoeng (tse kang aluminium le koporo), le matsoai a qhibilihisitsoeng, e leng se etsang hore e tšoanelehe haholo bakeng sa libaka tse senyang liindastering tsa lik'hemik'hale le tsa tšepe.

3. Matla a Phahameng a Mechini:Matla a ho kokobela mochesong wa kamore a fihla ho 300–500 MPa, ka ho boloka matla a betere mochesong o phahameng ho feta dihlahiswa tse hlwekileng tsa SiC, le ho hanyetsa ho matla ha tshusumetso.

4. Mocheso o sebetsang:Mocheso oa ts'ebetso oa nako e telele ke 1350℃, bokhoni ba ho mamella nako e khuts'oane ho fihlela ho 1500℃.

5. Ho Sireletsa ho Molemo:E boloka mocheso o motle oa motlakase esita le mochesong o phahameng, e thibela tšitiso ea lets'oao la thermocouple.

Meeli:

Khanyetso ea oxidation e batla e le tlase ho feta silicon carbide e nchafalitsoeng; tšebeliso ea nako e telele sepakapakeng se matla sa oxidation e ka lebisa ho peeling ha lera la oxide ea holim'a metsi.

Tafole ea Papiso ea Likarolo tsa Bohlokoa

| Tšobotsi | Si₃N₄-SiC | R-SiC | RB-SiC |

| Mocheso o Tshebetso wa Nako e Telele | 1350℃ | 1600℃ | 1200℃ |

| Khanyetso ea Thermal Shock | E ntle ka ho fetisisa | Ho lokile | Mahareng |

| Thepa ea Antioxidant | Ho lokile | E ntle ka ho fetisisa | Mahareng |

| Khanyetso ea ts'enyeho | E matla (e hanela li-acid le li-alkali /tšepe e qhibilihisitsoeng) | E matla (e hanela oxidation le mafome) | E mahareng (Qoba alkalis e matla/aluminium e qhibilihisitsoeng) |

| Ho ba le masoba | 3%–5% | 5%–8% | 1% |

| Khanyetso ea Tšusumetso | E matla | Bofokoli | Mahareng |

Liindasteri le Maemo a Tloaelehileng

1. NSiC thermocouple protection tube

Indasteri ea Lik'hemik'hale:Tekanyo ea mocheso ka har'a lijana tsa karabelo ea motheo oa asiti, lisele tsa electrolytic tsa letsoai le qhibilihisitsoeng, le litanka tsa polokelo ea mahareng tse senyang; e mamella ts'enyeho ea nako e telele e tsoang ho li-acid tse matla, li-alkali le letsoai le qhibilihisitsoeng; e loketse maemo a karabelo a sa khaotseng a nang le ho feto-fetoha ha mocheso khafetsa.

Indasteri ea Tšepe:Tekanyo ea mocheso oa tšepe e qhibilihisitsoeng ka har'a liforomo tsa aluminium tse qhibilihisitsoeng ka ho qhibilihisa, liforo tsa koporo tse qhibilihisang, le liforo tsa tšepe tse qhibilihisang tse se nang tšepe; e hanelang khoholeho ea tšepe e qhibilihisitsoeng, 'me e thibela ho thijoa ha eona mochesong o phahameng ho qoba tšitiso ea lets'oao la thermocouple.

Indasteri ea Thepa ea Kaho:Tekanyo ea mocheso ka har'a li-oven tsa lime tse sa khaotseng le li-oven tsa gypsum calcining; e khona ho sebetsana le ho futhumala le ho pholisa ka potlako ho bakoang ke ho qalisoa le ho koaloa ha oven; e hanela mafome a tsoang khase ea alkaline flue ka har'a oven.

2. Liphaephe tsa Tšireletso ea Thermocouple ea RSiC

Indasteri ea Thepa ea Kaho:Tekanyo ea mocheso libakeng tsa ho besa tsa ontong e potolohang ea samente, liontong tsa roller tsa ceramic, le liontong tsa tunnel tsa thepa e hanyetsang; e mamella mocheso o phahameng haholo oa 1600℃ le khoholeho e matla e tsoang phofong ea mocheso o phahameng, e loketse maemo a tsoelang pele a tlhahiso ea mocheso o phahameng.

Indasteri ea Tšepe:Tekanyo ea mocheso liphaepheng tsa ho phatloha ho chesang ha sebōpi sa mollo, lijana tsa tšepe tse qhibilihisitsoeng, le lisebelisoa tsa pele tsa phekolo ea tšepe e qhibilihisitsoeng; e ka sebelisoa nako e telele sepakapakeng se matla se etsang hore oxidize, e hanela ho bola ho bakoang ke khase ea flue ea mocheso o phahameng le slag ea tšepe.

Indasteri ea Khalase:Tekanyo ea mocheso ho li-regenerator tsa khalase tse qhibilihisang sebōpi le liforomo tse etsang khalase; e mamella ho bola le khoholeho ea mocheso o phahameng ho tsoa khalaseng e qhibilihisitsoeng, e fihlela litlhoko tse tsoelang pele tsa mocheso o phahameng oa tlhahiso ea khalase.

3. Liphaephe tsa Tšireletso ea Thermocouple ea RBSiC

Indasteri ea Tlhahiso ea Mechini:Tekanyo ea mocheso lifonong tsa kalafo ea mocheso, lifonong tsa ho tima ka khase, le lifonong tsa carburizing; li loketse maemo a tsitsitseng a mocheso o mahareng le o tlase, 'me li ka mamella khoholeho e bobebe ea likaroloana ka har'a sebōpi.

Indasteri ea Matla:Tekanyo ea mocheso bakeng sa liboiler tsa khatello ea sepakapaka, litofo tse chesang tse phatlohang, le lisebelisoa tsa ho khutlisa mocheso o litšila; e loketse sepakapaka se sa nke lehlakore kapa se fokolang, se fihlelang litlhoko tsa tekanyo ea mocheso o koetsoeng ho tloha khatellong e tlase ho isa ho e mahareng-e phahameng.

Lisebelisoa tsa Teko:Tekanyo ea mocheso bakeng sa lifono tse nyane tse ntšang metsi tse nang le khatello e phahameng le lifono tsa laboratori tse nang le li-tube; ho ba le masoba a tlase le ho se kene ha moea ho etsa hore e lokele libaka tse nyenyane tsa liteko tse koetsoeng ka khatello e phahameng.

Metallurgical

Khemikhale

Matla

Lifofane

Elektroniki

Li-Roller Kilns

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e fumaneha Motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa e hanyetsang. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea ontong, theknoloji le thepa e hanyetsang kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a tekheniki a matla, boleng bo botle ba sehlahisoa, le botumo bo botle. Feme ea rona e akaretsa lihekthere tse fetang 200 'me tlhahiso ea selemo le selemo ea thepa e hanyetsang e bōpehileng joaloka e ka ba lithane tse 30000 'me thepa e hanyetsang e sa bōpehang joaloka e hanyetsang ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa e hanyetsang li kenyelletsa:thepa e hanyetsang alkaline; thepa e hanyetsang silicon ea aluminium; thepa e sa bōpehang e hanyetsang; thepa e thibelang mocheso e thibelang mocheso; thepa e khethehileng e thibelang; thepa e sebetsang e thibelang bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Khafetsa

Na u hloka thuso? Etsa bonnete ba hore u etela liforamo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, fektheri ea rona e ikhethile ka ho hlahisa thepa e hanyetsang ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ea kamora thekiso.

Bakeng sa ts'ebetso e 'ngoe le e 'ngoe ea tlhahiso, RBT e na le sistimi e felletseng ea QC bakeng sa sebopeho sa lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa, 'me setifikeiti sa boleng se tla romelloa le thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho latela bongata, nako ea rona ea ho tlisa thepa e fapane. Empa re tšepisa ho e romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ehlile, re fana ka disampole tsa mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e ntle ka ho fetisisa ho latela boemo ba hau.

Re ntse re etsa thepa e hanyetsang mocheso ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le boiphihlelo bo bongata, re ka thusa bareki ho rala li-kiln tse fapaneng le ho fana ka tšebeletso ea ho emisa hang feela.