Liphaephe tse Pholisang tsa Silicon Carbide

Lihlopha tsa lihlahisoa

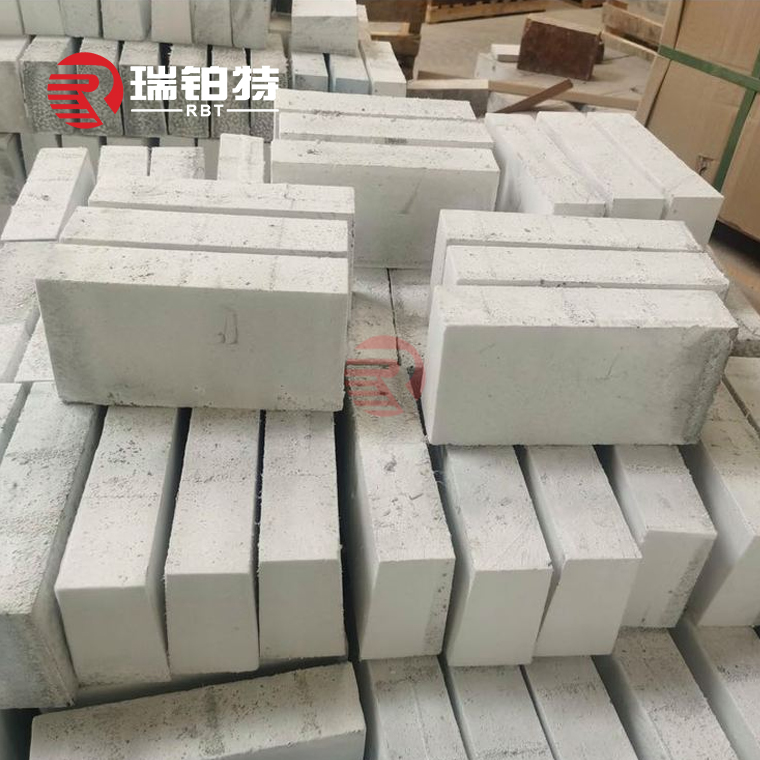

1. Lihlahisoa tsa sintered silicon carbide(RBSiC Products)

Reaction bonded silicon carbide (RBSiC) ke lisebelisoa tse tsoetseng pele tsa boenjiniere tsa ceramic tse hlahisang karolo ea bonding ea silicon carbide ka ho sebetsana le khabone e sa lefelloeng ka silicon ea mokelikeli tlas'a maemo a phahameng a mocheso. Likarolo tsa eona tsa mantlha li kenyelletsa matrix ea silicon carbide (SiC) le silicon ea mahala (Si). Ea pele e fana ka thepa e ntle ea mochini, ho hanyetsa ho roala le botsitso ba mocheso o phahameng,

ha ea morao-rao e tlatsa li-pores pakeng tsa likaroloana tsa silicon carbide ho matlafatsa sepakapaka le botšepehi ba sebopeho sa thepa.

(1) Litšobotsi:

Ho tsitsisa mocheso o phahameng:Boholo ba mocheso oa ho sebetsa 1350 ℃.

Wear resistance le corrosion resistance :E loketse maemo a thata a ho sebetsa a mocheso o phahameng, acid, alkali le tšepe e qhibilihisitsoeng. "

Ts'ebetso e phahameng ea mocheso le coefficient e tlase ea katoloso ea mocheso:Thermal conductivity e ka holimo ho 120-200 W/(m·K), 'me coefficient ea ho atolosa mocheso ke 4.5×10⁻⁶ K⁻¹ ka katleho, e thibelang ho phunyeha ha mocheso le mokhathala oa mocheso. "

Anti-oxidation:Setsi sa tšireletso sa silika se teteaneng se hlahisoa ka holim'a mocheso o phahameng ho lelefatsa bophelo ba ts'ebeletso.

(2) Lihlahisoa tse ka Sehloohong:

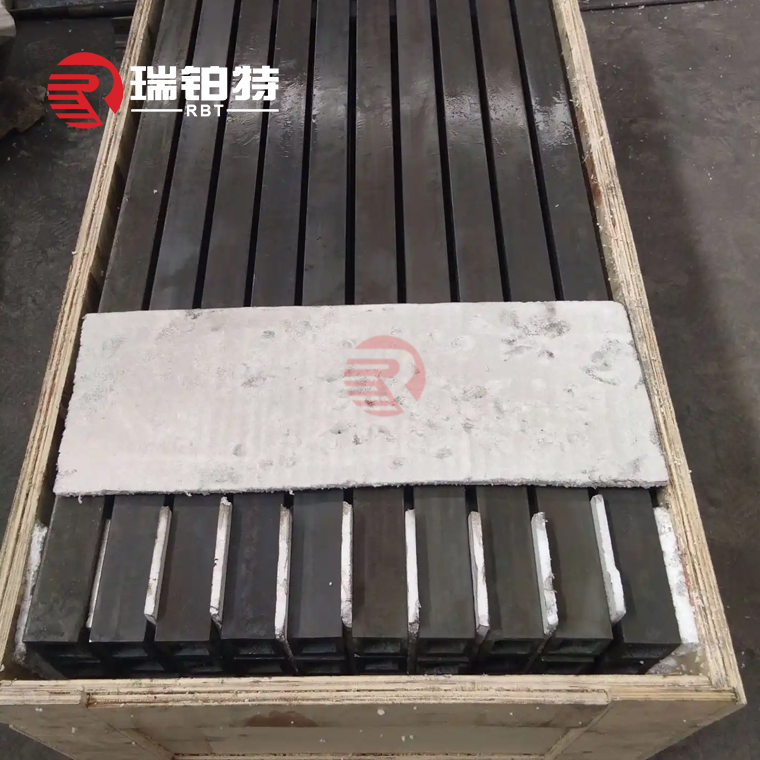

"Sekhahla sa silicon carbide:e sebelisetsoang sebopeho se jereng thepa ea litopo tsa lithanele, libotlolo tsa shuttle le lisebelisoa tse ling tsa indasteri, tse nang le khanyetso e phahameng ea mocheso.

"

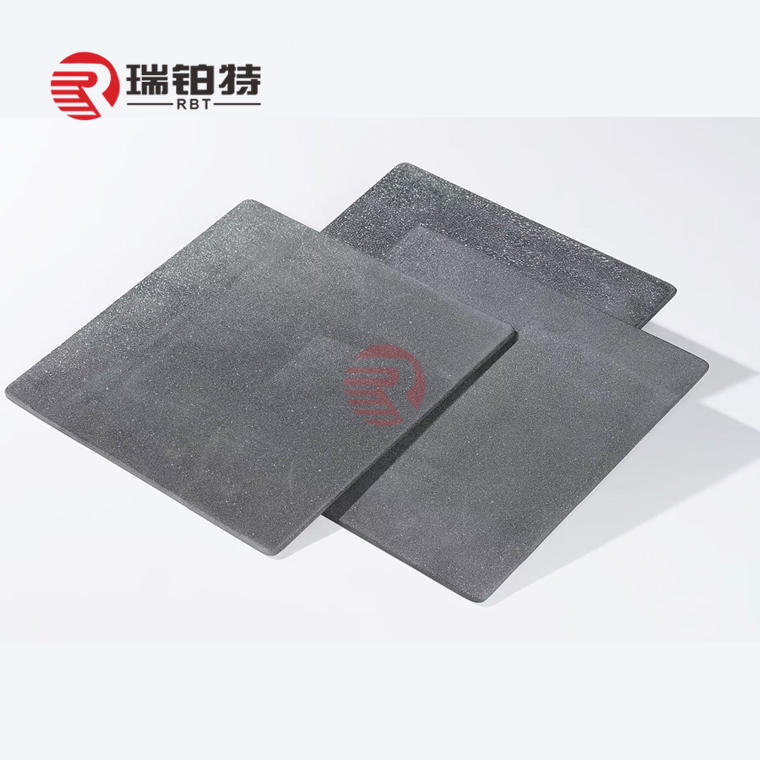

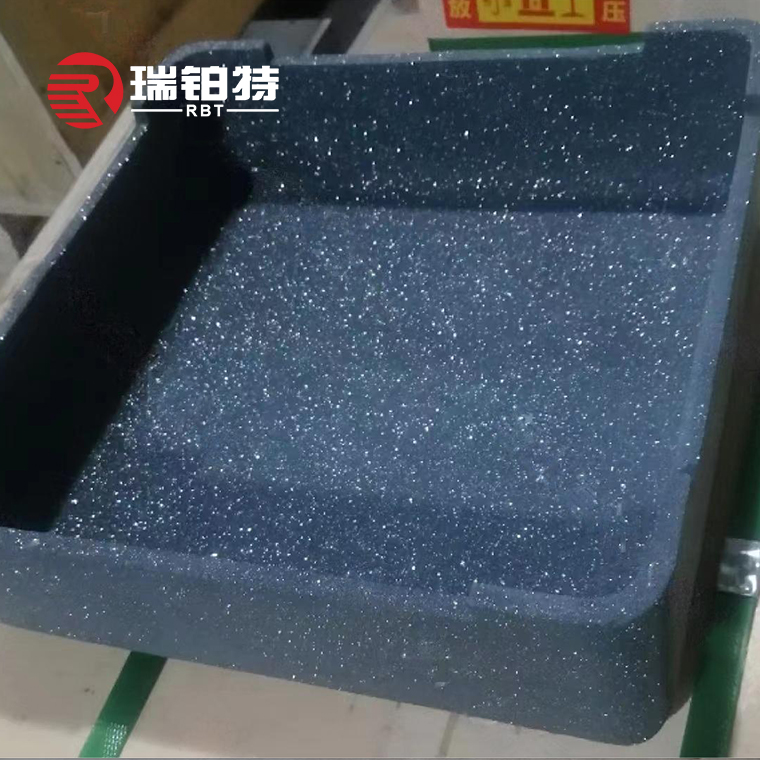

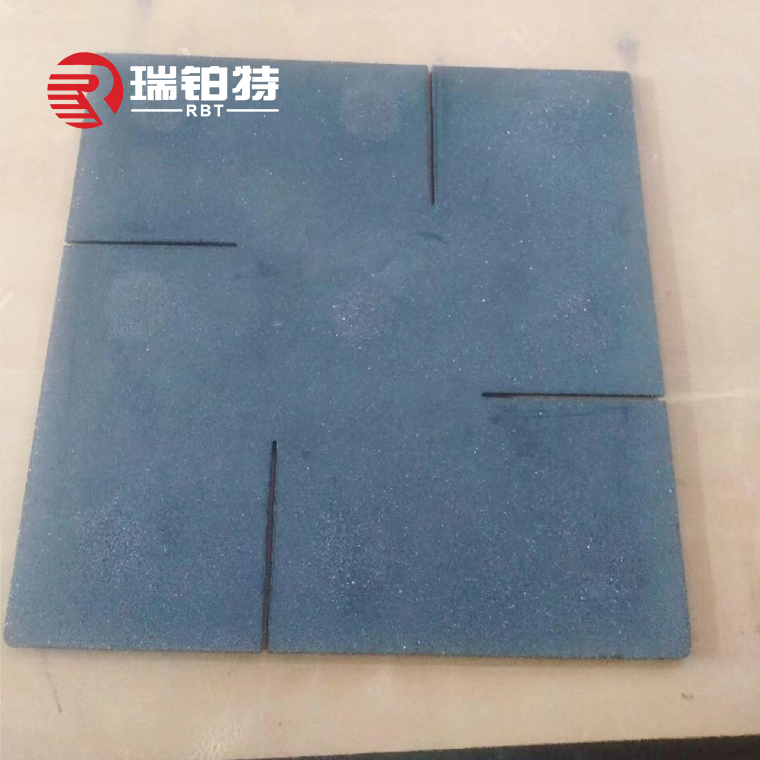

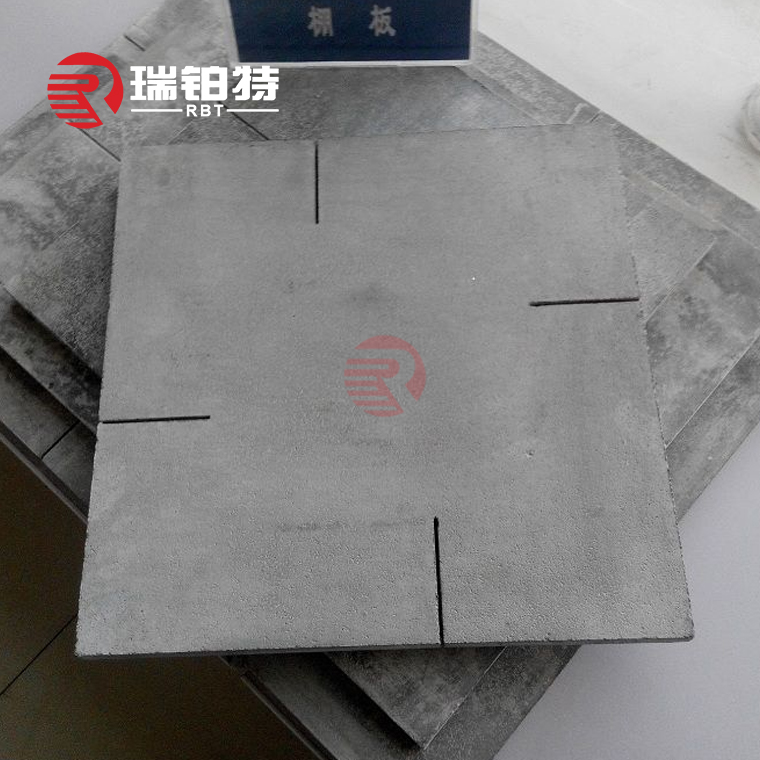

Letlapa la silicon carbide:e sebelisetsoang lisebelisoa tsa refractory li-kilns, tse nang le litšobotsi tsa oxide bonding. "

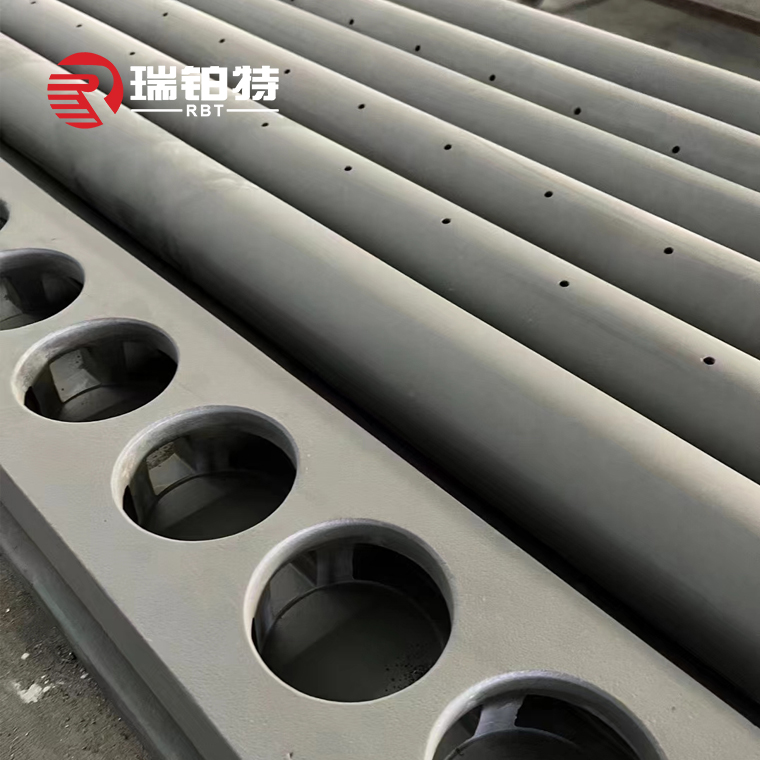

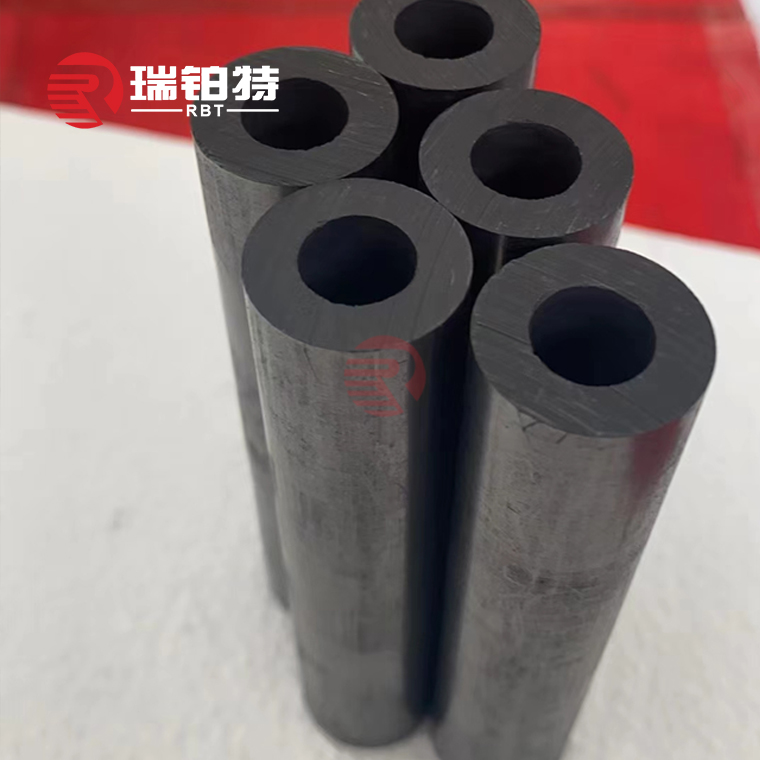

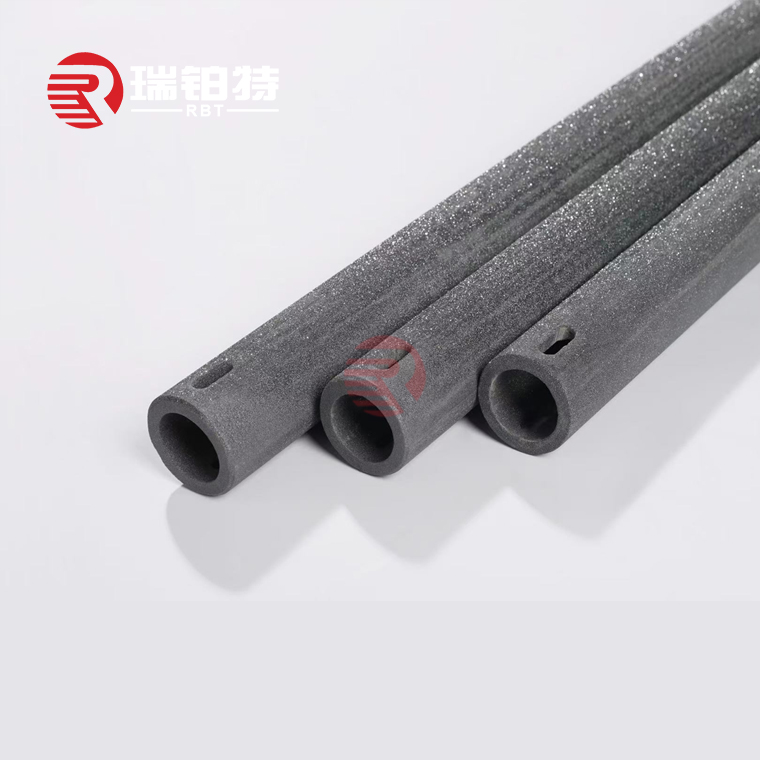

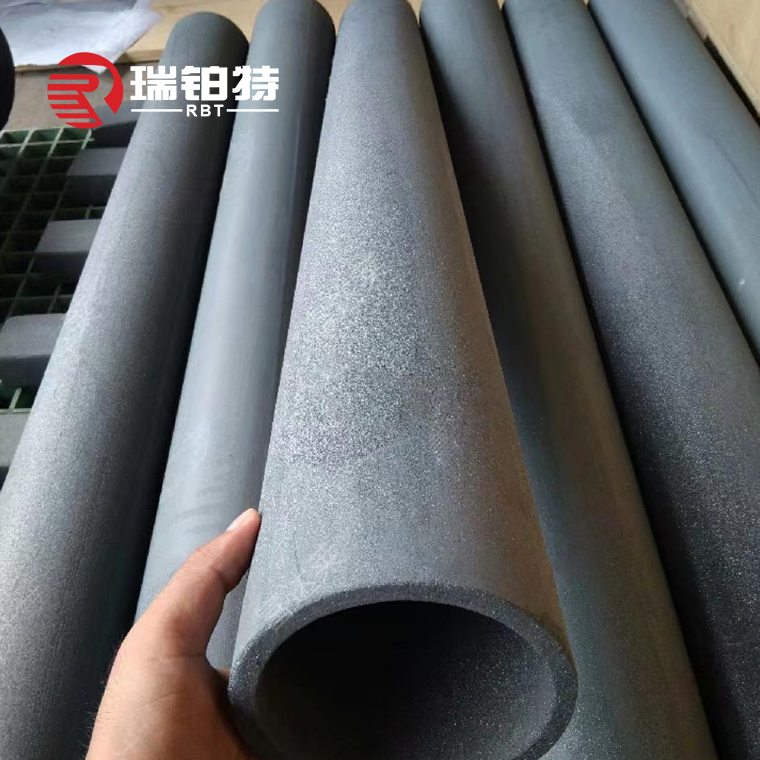

Pipe ea silicon carbide:e sebelisetsoang liphaephe le lijana libakeng tse fapaneng tsa mocheso o phahameng. "

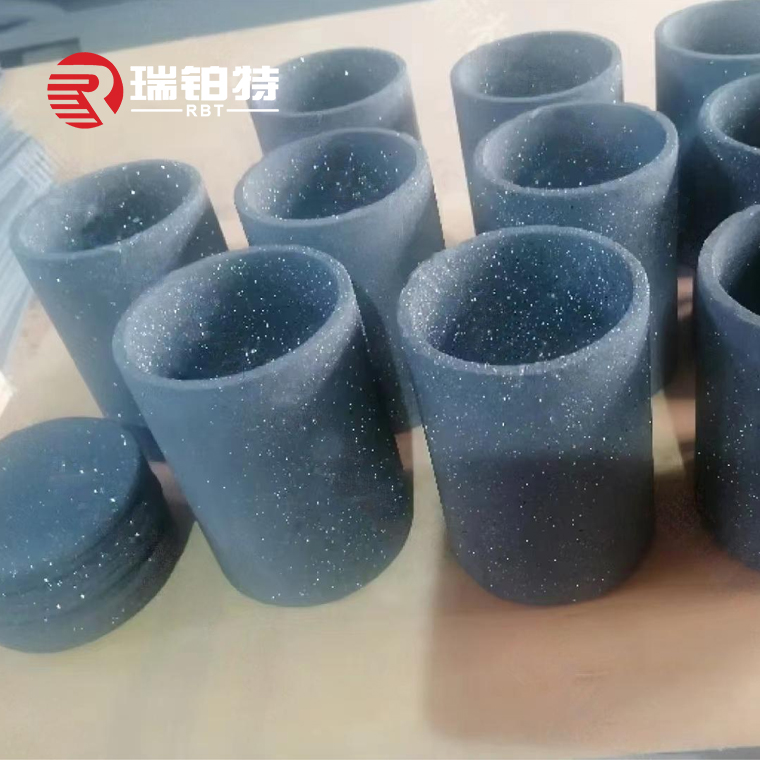

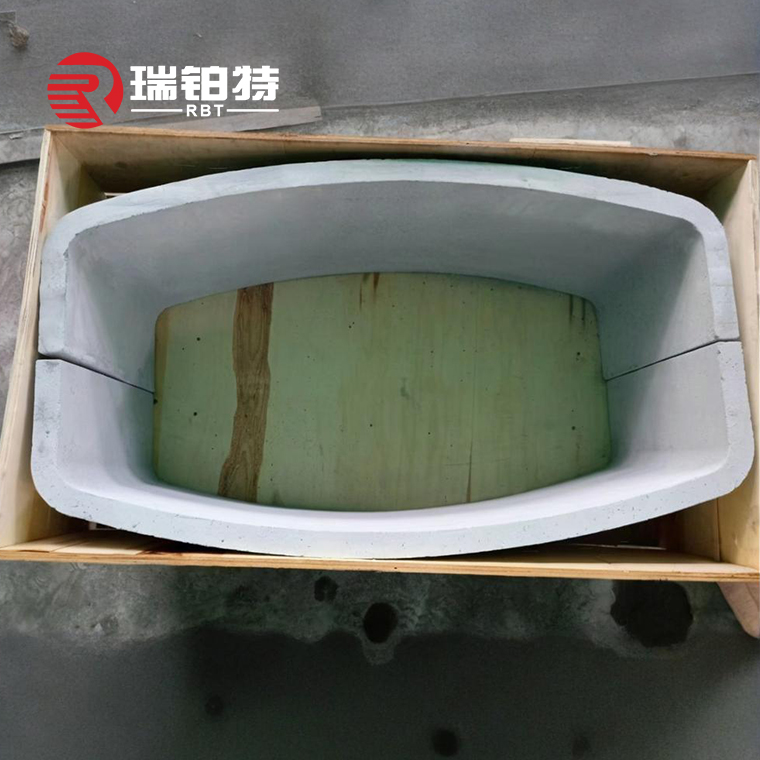

Silicon carbide crucible le sagger:e sebelisetsoang ho qhibilihisa mocheso o phahameng le ho boloka thepa. "

Lesale la tiiso la silicon carbide:e sebelisoa haholo masimong a likoloi, sefofane le indasteri ea lik'hemik'hale, 'me e ka boloka ts'ebetso e tšepahalang ea ho tiisa mocheso o phahameng le maemo a khatello e phahameng. "

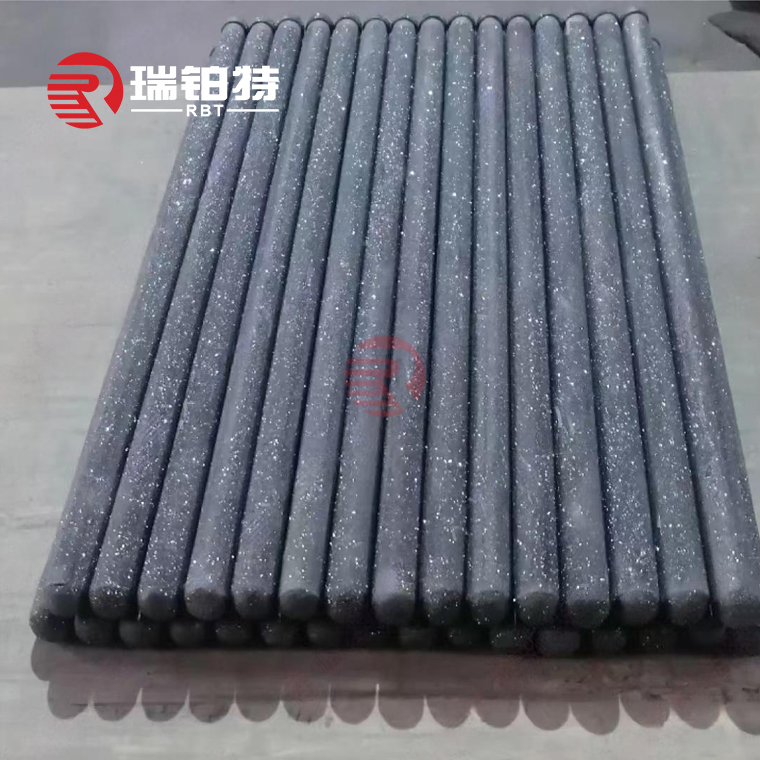

Silicon carbide roller:e sebelisetsoang li-roller kilns, tse nang le litšobotsi tsa anti-oxidation, matla a ho feto-fetoha ha mocheso o phahameng le bophelo bo bolelele ba ts'ebeletso. "

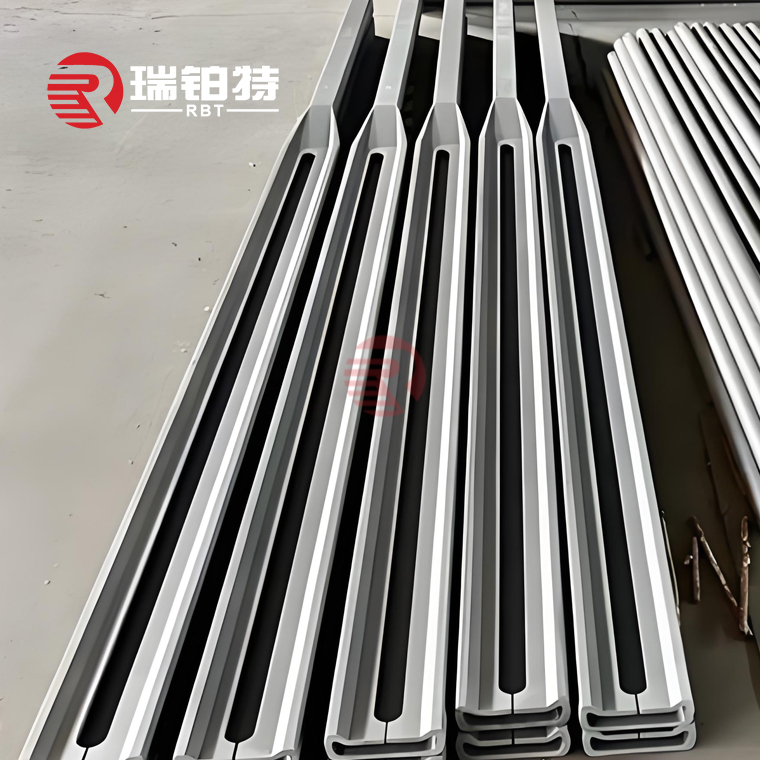

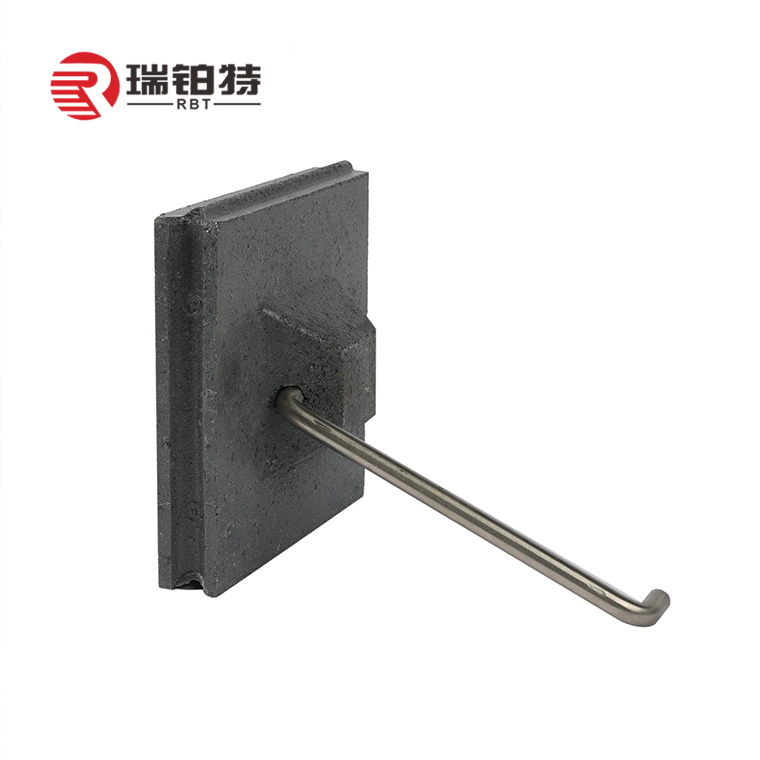

Liphaephe tse pholileng tsa silicon carbide:se sebedisoang bakeng sa sebaka sa ho pholisa sa li-roller kilns, tse nang le khanyetso e ntle ho feteletseng

mohatsela le mocheso. "

Silicon carbide bunner nozzle:e sebelisoa bakeng sa libotlolo tse fapaneng tsa oli, khase le liindasteri tse ling, tse nang le litšobotsi tsa serame se feteletseng le ho hanyetsa mocheso, ho hanyetsa ho roala, ho hanyetsa mocheso o phahameng, joalo-joalo. "

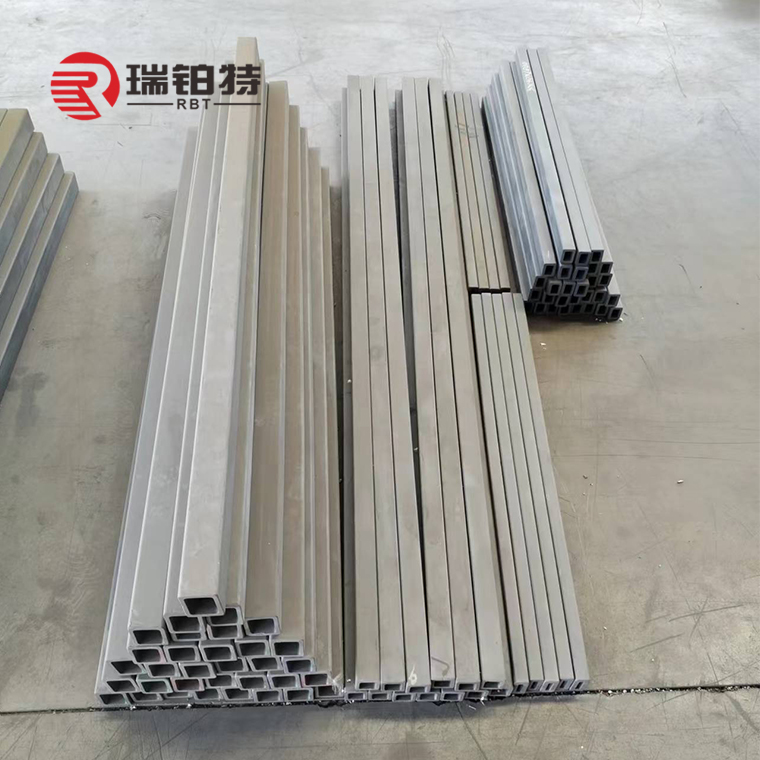

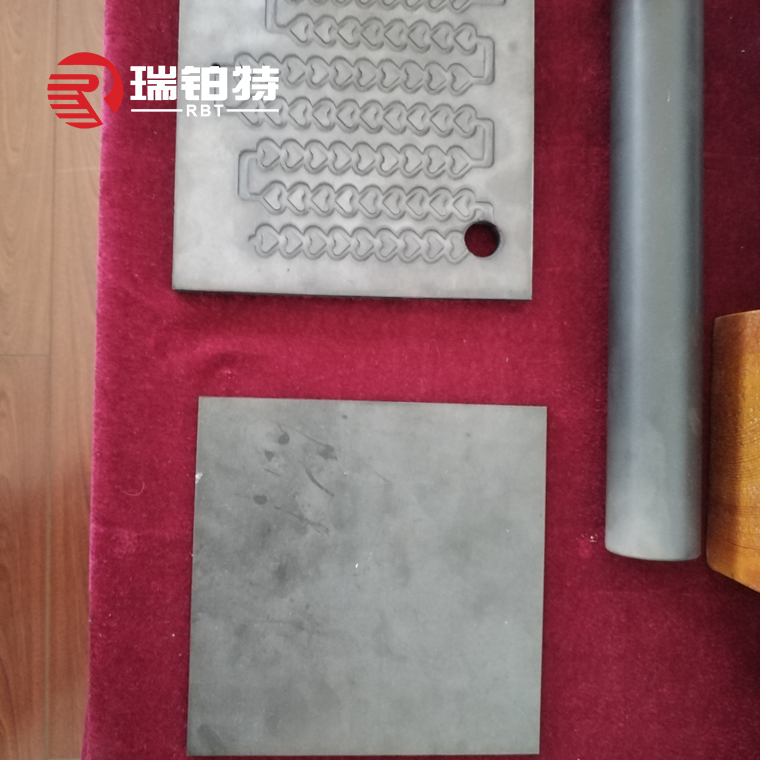

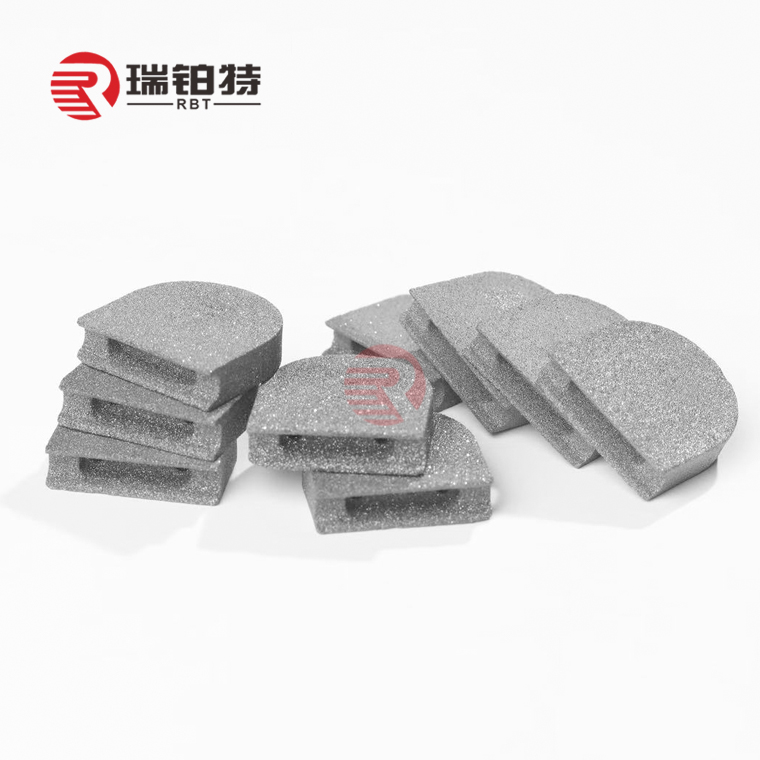

Likarolo tse ikhethileng tse nang le sebopeho se ikhethileng:Tlhahiso e ikhethileng ea likarolo tse fapaneng tse nang le sebopeho se ikhethileng ho latela litlhoko tsa bareki, joalo ka lipoleiti tse bōpehileng joaloka litlhapi, lithupa tse leketlileng, likarolo tsa tšehetso, joalo-joalo.

Lintlha Litšoantšo

Beam ea Silicon Carbide

Silicon Carbide Cantilever Paddle

Silicon Carbide Nozzle

Silicon Carbide Burner Tube

Liphaephe tse Pholisang tsa Silicon Carbide

Silicon Carbide Nozzle

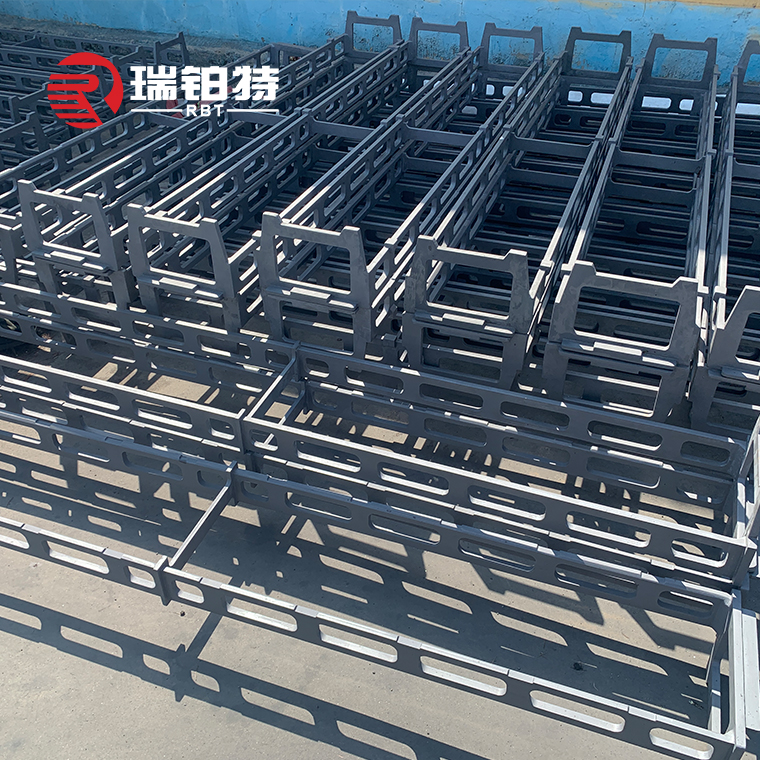

Silicon Carbide Boat Bracket

Lesela le hananang le ho rwala

Sekepe sa Silicon Carbide Wafer

Index ea Lihlahisoa

| Lihlahisoa tsa RBSiC (SiSiC). | ||

| Ntho | Yuniti | Lintlha |

| Mocheso o Moholo oa Kopo | ℃ | ≤1350 |

| Botenya | g/cm3 | ≥3.02 |

| Open Porosity | % | ≤0.1 |

| Matla a Kobehang | Mpa | 250(20℃); 280(1200℃) |

| Modulus ea Elastictiy | GPA | 330(20℃); 300(1200℃) |

| Thermal Conductivity | W/mk | 45(1200℃) |

| Mocheso oa Katoloso ea Mocheso | K-1*10-6 | 4.5 |

| Bothata ba Moh | | 9.15 |

| Acid Alkaline-Bopaki | | E kgabane |

2. Lihlahisoa tsa sintered silicon carbide (Lihlahisoa tsaSSiC)

Lihlahisoa tsa silicon carbide tse se nang khatello ke mofuta oa lisebelisoa tsa ceramic tsa theknoloji e phahameng tse lokiselitsoeng ke ts'ebetso e sa hatelleheng ea sintering. Karolo ea eona e ka sehloohong ke silicon carbide (SiC), 'me karolo e itseng ea li-additives e kenngoa. Ka theknoloji e tsoetseng pele ea ceramic, e entsoe ka lirafshoa tse se nang porous, seamless, le tse se nang khatello ea maikutlo tse phahameng haholo.

(1) Litšobotsi:

Ho hanyetsa mocheso o phahameng:tšebeliso e tloaelehileng ho 1800 ℃;

High thermal conductivity:e lekanang le ho tsamaisa mocheso oa graphitelisebelisoa;

Boima bo phahameng:boima ke ea bobeli feela ho daemane le cubic boron nitride;

Corrosion resistance:acid e matla le alkali e matla ha e na kutu ho eona, 'me ho hanyetsa ha eona ho molemo ho feta tungsten carbide le aluminium oxide;

Boima bo bobebe:boima ba 3.10g / cm3, haufi le aluminium;

Ha ho deformation:coefficient e nyane haholo ea katoloso ea mocheso,

E hanyetsa mocheso oa mocheso:thepa e ka mamella liphetoho tse potlakileng tsa mocheso, ho tšoha ha mocheso, ho pholisa ka potlako le ho futhumatsa, 'me ho na le ts'ebetso e tsitsitseng.

(2) Lihlahisoa tse ka Sehloohong:

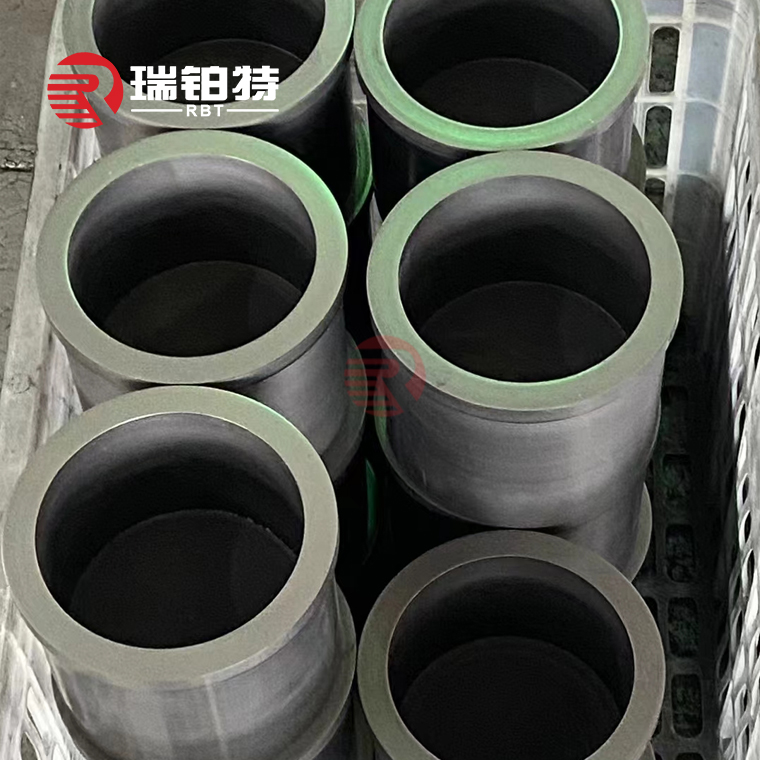

Li-rings tsa tiiso:Lihlahisoa tsa sintered silicon carbide hangata li sebelisoa ho etsa mehele e tiisang e sa senyeheng le e thibelang ho bola le libere tse thellang. "

Likarolo tsa mechini:Ho kenyelletsa li-bearings tsa mocheso o phahameng, litiiso tsa mochini, li-nozzles, li-valve tsa moea, 'mele oa pompo, lisebelisoa, joalo-joalo.

Thepa ea lik'hemik'hale:E sebelisetsoa ho etsa liphaephe tse thibelang ho bola, litanka tsa polokelo, li-reactors le li-seal. "

Lisebelisoa tsa elektroniki:Indastering ea matla, silicon carbide e se nang khatello e sebelisoa ho etsa li-resistors tse nang le mocheso o phahameng, lisebelisoa tsa ho futhumatsa motlakase le li-switches tse nang le matla a phahameng. "

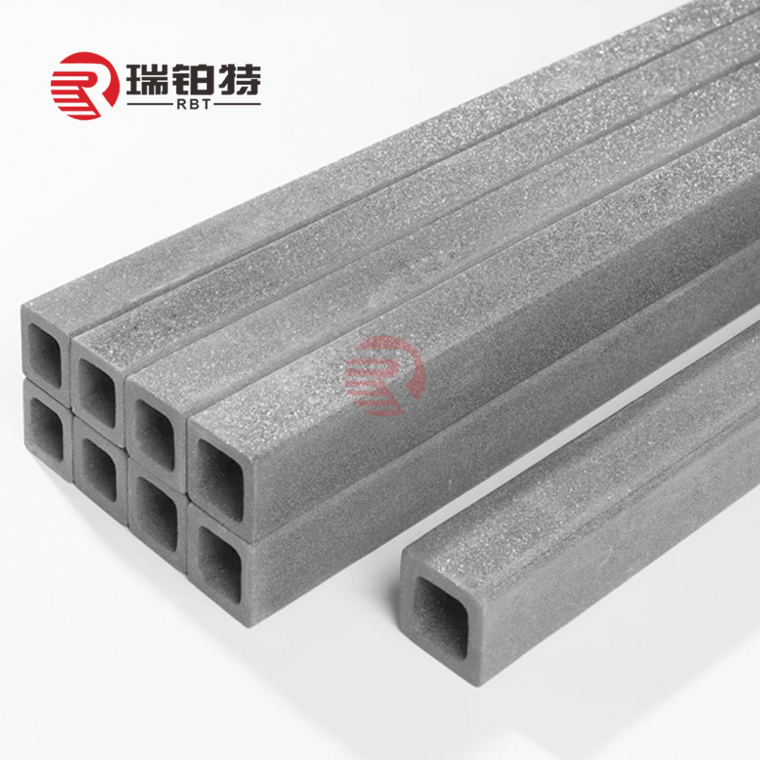

Kilne furniture:Joalo ka liforeimi tse jereng meroalo, lirolara, li-nozzles tsa malakabe, lipeipi tse pholisang, joalo-joalo ka har'a libotlolo tsa lithanele, liotlolong tsa shuttle le libotlolo tse ling tsa indasteri. "

Lintlha Litšoantšo

Silicon Carbide Seal Ring

Pipe ea Silicon Carbide

Silicon Carbide Liners

Beam ea Silicon Carbide

Letlapa la Silicon Carbide

Moqomo o silang oa Silicon Carbide

Index ea Lihlahisoa

| Lihlahisoa tsa SSiC | ||

| Ntho | Yuniti | Sephetho |

| Ho thatafala | HS | ≥115 |

| Porosity Rate | % | <0.2 |

| Botenya | g/cm3 | ≥3.10 |

| Matla a Khatellang | Mpa | ≥2500 |

| Matla a Kobehang | Mpa | ≥380 |

| Coefficient of Katoloso | 10-6/℃ | 4.2 |

| Litaba tsa SiC | % | ≥98 |

| Free Si | % | <1 |

| Elastic modulus | GPA | ≥410 |

| Mocheso o Moholo oa Kopo | ℃ | 1400 |

3. Sehlahisoa sa silicon carbide e nchafalitsoeng(RSiC Products)

Recrystallized Silicon Carbide Products ke sehlahisoa sa refractory se entsoeng ka silicon carbide e hloekileng e le thepa e tala. Ntho ea eona e ka sehloohong ke hore ha ho na karolo ea bobeli 'me e entsoe ka 100% α-SiC.

(1) Litšobotsi:

Ho thatafala haholo:Ho thatafala ha eona ho latela daemane feela, 'me e na le matla a holimo haholo a mochini le ho tiea. "

Ho hanyetsa mocheso o phahameng:E ka boloka ts'ebetso e tsitsitseng tikolohong ea mocheso o phahameng 'me e loketse mefuta e fapaneng ea mocheso oa 1350 ~ 1600 ℃. "

Khanyetso e matla ea corrosion:E na le khanyetso e phahameng ea kutu ho mefuta e fapaneng ea mecha ea litaba mme e ka bolokathepa ea mochini nako e telele libakeng tse fapaneng tse senyang. "

Ho hanyetsa oxidation e ntle:E na le khanyetso e ntle ea oxidation mme e khona ho sebetsa ka mokhoa o tsitsitseng mochesong o phahameng. "

Ho hanyetsa mocheso o motle oa mocheso:E sebetsa hantle tikolohong e nang le liphetoho tse potlakileng tsa mocheso 'me e loketse tikoloho ea mocheso oa mocheso. "

Ha ho na shrinkage nakong ea sintering:Ha e fokotsehe nakong ea ts'ebetso ea sintering, 'me ha ho na khatello e setseng e tla hlahisoa ho baka deformation kapa ho phunyeha ha sehlahisoa. E loketse ho lokisoa ha likarolo tse nang le libopeho tse rarahaneng le ho nepahala ho phahameng.

(2) Lihlahisoa tse ka Sehloohong:

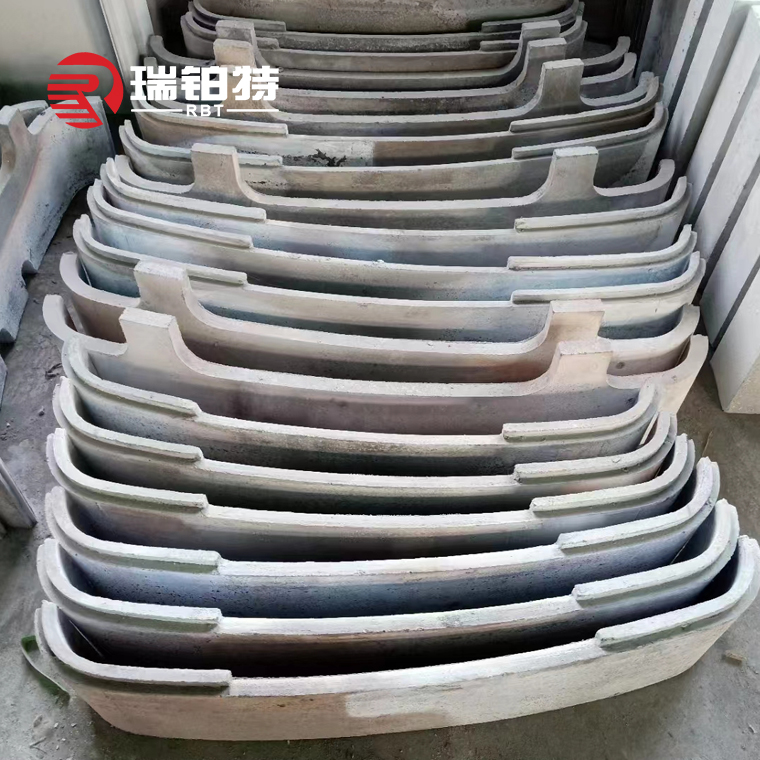

Lisebelisoa tsa Kiln furniture:Haholo-holo e sebelisoa bakeng sa thepa ea ka tlung, e na le melemo ea ho boloka matla, ho eketsa molumo o sebetsang oa sebōpi, ho khutsufatsa potoloho ea ho chesa, ho ntlafatsa katleho ea tlhahiso ea sebōpi le melemo e phahameng ea moruo. "

Li-nozzles tsa bunner:E ka sebelisoa e le lihlooho tsa li-nozzle tse tukang 'me e loketse libaka tse phahameng tsa mocheso. "

Li-tubes tse futhumatsang mahlaseli a ceramic:Li-tubes tsena tse futhumatsang li nka monyetla oa botsitso ba mocheso o phahameng le ho hanyetsa kutu ea silicon carbide e nchafalitsoeng 'me li loketse lits'ebetso tse fapaneng tsa indasteri ea mocheso o phahameng. "

Li-tubes tsa tšireletso ea likaroloana:Haholo-holo libopi tsa sepakapaka, lihlahisoa tsa silicon carbide li sebelisoa e le li-tubes tsa ts'ireletso tse nang le mocheso o phahameng o phahameng le ho hanyetsa kutu. "

'Mele oa pompo ea mocheso o phahameng, li-impellers tsa pompo, li-bearings, matlo a enjene:Lefapheng la likoloi, liindasteri tsa sefofane le tsa sesole, lisebelisoa tsa silicon carbide tse nchafalitsoeng li entsoe ka 'mele oa mocheso o phahameng oa mocheso, li-impellers, li-bearings le li-engine housings, joalo-joalo, ho nka monyetla oa ho hanyetsa mocheso oa bona o phahameng, ho hanyetsa ha acid le alkali corrosion le ho hanyetsa ho roala. "

Lintlha Litšoantšo

Likarolo tse entsoeng ka Silicon Carbide

Letlapa la Silicon Carbide

Silicon Carbide Roller

Beam ea Silicon Carbide

Li-tubes tsa Silicon Carbide Protection

Kiln Furniture

Silicon Carbide Sagger

Silicon Carbide Crucible

Letlapa la Silicon Carbide

Silicon Carbide Lgniter

Pipe ea Silicon Carbide

Silicon Carbide Burner

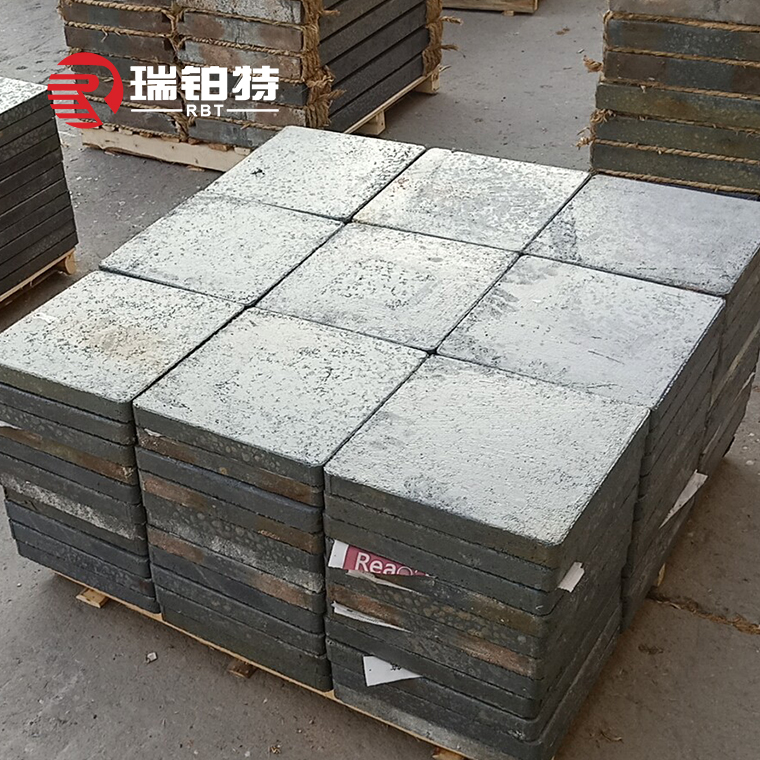

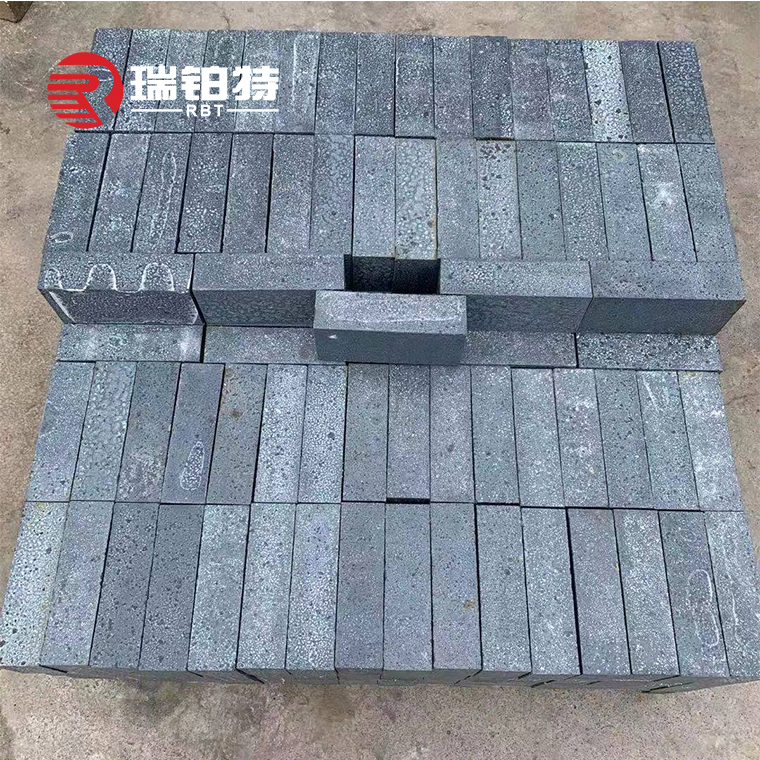

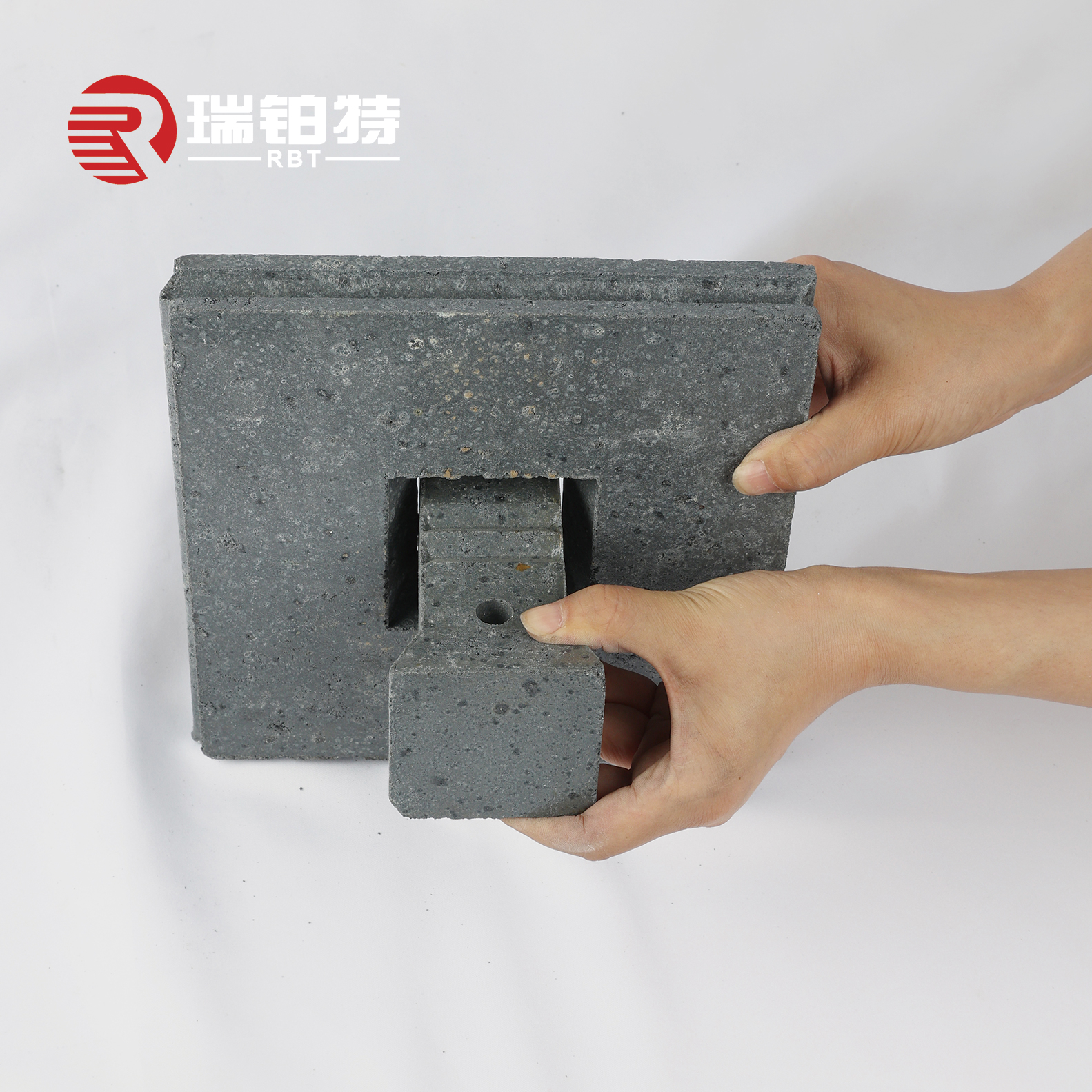

4. Silicon nitride bonded silicon carbide products(NSiC Products)

Silicon nitride bonded silicon carbide lihlahisoa ke lintho tse entsoeng ka ho kenyelletsa SiC aggregate ho phofo ea silicon ea indasteri, e sebetsanang le naetrojene ka mocheso o phahameng ho hlahisa Si3N4 le ho kopanya ka thata le likaroloana tsa SiC.

(1) Litšobotsi:

Ho thatafala haholo:The Mohs hardness ea silicon nitride bonded silicon carbide lihlahisoa ke hoo e ka bang 9, ea bobeli ho ea daemane, 'me ke thepa e nang le boima bo phahameng har'a thepa e seng ea tšepe. "

Matla a mocheso o phahameng:Lithempereichara tse phahameng tsa 1200-1400 ℃, matla le boima ba thepa e lula e batla e sa fetohe, 'me mocheso o sireletsehileng oa tšebeliso o ka fihla ho 1650-1750 ℃.

"

Thermal stability:E na le coefficient e nyane ea katoloso ea mocheso le conductivity e phahameng ea mocheso, ha e bonolo ho hlahisa khatello ea mocheso, e na le botsitso bo botle ba mocheso oa mocheso le khanyetso ea creep, 'me e loketse libaka tse batang haholo le tse chesang haholo. "

Ho tsitsa ha lik'hemik'hale:Ha e khone ho bola ebile ha e na oxidation, 'me e ka lula e tsitsitse libakeng tse fapaneng tsa lik'hemik'hale. "

Wear resistance:E na le khanyetso e ntle ea ho roala 'me e loketse lits'ebetso tse fapaneng tsa indasteri tse nang le moaparo o matla.

(2) Lihlahisoa tse ka Sehloohong:

Litene tsa Refractory:e sebelisoa haholo ho aluminium ea electrolytic, libono tsa ho phatloha ha tšepe, libono tsa arc tse ka tlas'a metsi le liindasteri tse ling, tse nang le litšobotsi tsa ho hanyetsa mocheso o phahameng, ho hanyetsa kutu, le ho hanyetsa khoholeho.

Fenishara ea Kiln:e sebelisetsoang mabili a sila a ceramic, porcelain ea motlakase e matla, li-kilns tsa indasteri, joalo-joalo, tse nang le bokhoni bo botle ba ho jara le ho hanyetsa mocheso o phahameng.

Lihlahisoa tse nang le sebopeho se ikhethileng:e sebelisetsoang ho lahla metallurgical e se nang ferrous, matla a mocheso, libono tsa arc tse ka tlas'a metsi le liindasteri tse ling, tse nang le litšobotsi tsa ho hanyetsa ho apara le ho hanyetsa mocheso o phahameng.

Likarolo tsa refractory:ho kenyelletsa le li-tubes tsa ts'ireletso ea thermocouple, li-tubes tsa riser, matsoho a futhumatsang, joalo-joalo, tse sebelisoang liipone tse nang le mocheso o phahameng oa mocheso le libaka tse fapaneng tsa sepakapaka, tse nang le conductivity e phahameng ea mocheso le ho hanyetsa kutu.

Lintlha Litšoantšo

Letlapa le entsoeng ka Silicon Carbide

Letlapa le entsoeng ka Silicon Carbide

Letlapa le entsoeng ka Silicon Carbide

Letlapa le entsoeng ka Silicon Carbide

Letlapa le entsoeng ka Silicon Carbide

Silicon Carbide Radiation Tubes

Pipe ea Silicon Carbide

Letlapa le entsoeng ka Silicon Carbide

Likarolo tse entsoeng ka Silicon Carbide

Li-tubes tsa Silicon Carbide Protection

Letlapa la Silicon Carbide

Litene tsa Silicon Carbide

5. Lihlahisoa tsa silicon carbide tse nang le oksijene

Lihlahisoa tsa silicon carbide tse nang le oksijene li entsoe ka ho kopanya likaroloana tsa silicon carbide le phofo ea oxide (joalo ka silicon dioxide kapa mullite), ho hatella le ho sila ka mocheso o phahameng. Tšobotsi ea eona ke hore nakong ea ts'ebetso ea sintering le tšebeliso, filimi ea oxide e phuthetsoe holim'a likaroloana tsa silicon carbide, tse ntlafatsang haholo ho hanyetsa ha oxidation le matla a phahameng a mocheso.

E na le litšoaneleho tsa matla a phahameng a mocheso o phahameng oa mocheso, botsitso bo botle ba mocheso oa mocheso, mocheso o phahameng oa mocheso, ho hanyetsa ho roala le ho hanyetsa ka matla ho fapaneng le khoholeho ea sepakapaka, 'me ke thepa e ntle ea ho boloka matla bakeng sa libōpi tsa indasteri.

(2) Lihlahisoa tse ka Sehloohong:

Silicon dioxide e kopantsoeng le lihlahisoa tsa silicon carbide:Sehlahisoa sena se sebelisa silicon dioxide (SiO2) e le mohato o tlamang. Hangata 5% ~ 10% ea silicon dioxide phofo kapa phofo ea quartz e kopantsoe le likaroloana tsa silicon carbide (SiC). Ka linako tse ling ho eketsoa flux. Ka mor'a ho e hatella le ho theha, e chesoa ka sebōping se akaretsang. Tšobotsi ea eona ke hore nakong ea ts'ebetso ea ho thunya le ho sebelisoa, filimi ea silicon dioxide e phuthetsoe holim'a likaroloana tsa silicon carbide, e leng ho ntlafatsang haholo ho hanyetsa ha oxidation le matla a phahameng a mocheso. Sehlahisoa sena se sebelisoa haholo lishelefong tsa sebōpi bakeng sa ho chesa porcelain (> 1300 ℃), 'me bophelo ba eona ba ts'ebeletso bo feta.

e imenne habeli ea lihlahisoa tse entsoeng ka letsopa tsa silicon carbide. "

Lihlahisoa tsa silicon carbide tse kopantsoeng ke Mullite:Sehlahisoa sena se eketsa phofo ea α-Al2O3 le phofo ea silicon dioxide ho metsoako ea silicon carbide. Kamora ho hatella le ho theha, Al2O3 le SiO2 li kopantsoe ho etsa mullite nakong ea ts'ebetso ea sintering. Nakong ea ts'ebeliso, silicon dioxide e entsoeng ke oxidation ea silicon carbide e etsa karolo e itseng ea mullite le Al2O3. Boitsebiso bona bo na le botsitso bo botle ba mocheso oa mocheso 'me bo sebelisoa haholo ha ho etsoa li-sagger tsa porcelain le lishelefo.

Lintlha Litšoantšo

Letlapa la Silicon Carbide

Litene tsa Silicon Carbide

Letlapa la Silicon Carbide

SiC Microcrystalline Pipe

SiC Microcrystalline Board

SiC Microcrystalline Board

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e sebakeng sa Zibo City, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea lintho tse refractory. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea sebōpi, thekenoloji, le thepa ea ho rekisa kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a matla a tekheniki, boleng bo botle ba sehlahisoa le botumo bo botle. Feme ea rona e na le lihekthere tse fetang 200 mme tlhahiso ea selemo le selemo ea thepa e bōpehileng joaloka lithane tse ka bang 30000 'me thepa ea refractory e sa bopehang ke lithane tse 12000.

Lihlahisoa tsa rona tsa mantlha tsa thepa ea refractory li kenyelletsa:lisebelisoa tsa alkaline refractory; lisebelisoa tsa aluminium silicon refractory; thepa e sa bōpehang refractory; lisebelisoa tse thibelang mocheso oa mocheso; lisebelisoa tse khethehileng tsa refractory; lisebelisoa tse sebetsang tsa refractory bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Khafetsa

U hloka thuso? Etsa bonnete ba hore u etela liforomo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, feme ea rona e khethehile ho hlahisa thepa ea refractory ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ka mor'a ho rekisa.

Bakeng sa ts'ebetso e 'ngoe le e' ngoe ea tlhahiso, RBT e na le tsamaiso e feletseng ea QC bakeng sa metsoako ea lik'hemik'hale le thepa ea 'mele. 'Me re tla hlahloba thepa,' me setifikeiti sa boleng se tla romelloa ka thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho itšetlehile ka bongata, nako ea rona ea ho fana e fapane. Empa re ts'episa ho romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ha e le hantle, re fana ka mehlala ea mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e molemohali ho latela boemo ba hau.

Re 'nile ra etsa thepa ea refractory ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le phihlelo e ruileng, re ka thusa bareki ho rala li-kilns tse fapaneng le ho fana ka ts'ebeletso e le 'ngoe.