SiC Heating Element

Tlhahisoleseding ya Sehlahiswa

Lithupa tsa silicon carbideli na le sebopeho sa molamu le li-tubular tse se nang tšepe tse phahameng tsa mocheso tse futhumatsang tse entsoeng ka botala bo botala bo botala ba hexagonal silicon carbide e le thepa e ka sehloohong e tala, e entsoeng ka likheo ho latela tekanyo e itseng ea thepa, 'me e sirelelitsoe ho 2200 ° C bakeng sa siliconization e phahameng ea mocheso, recrystallization le sintering.Mocheso o tloaelehileng oa tšebeliso sebakeng sa oxidizing o ka fihla ho 1450 ° C, 'me tšebeliso e tsoelang pele e ka fihla lihora tse 2000.

Likaroloana

Lintlha Litšoantšo

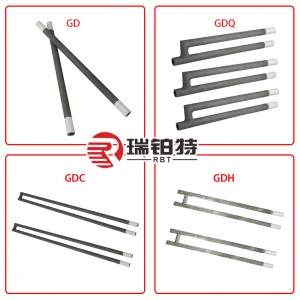

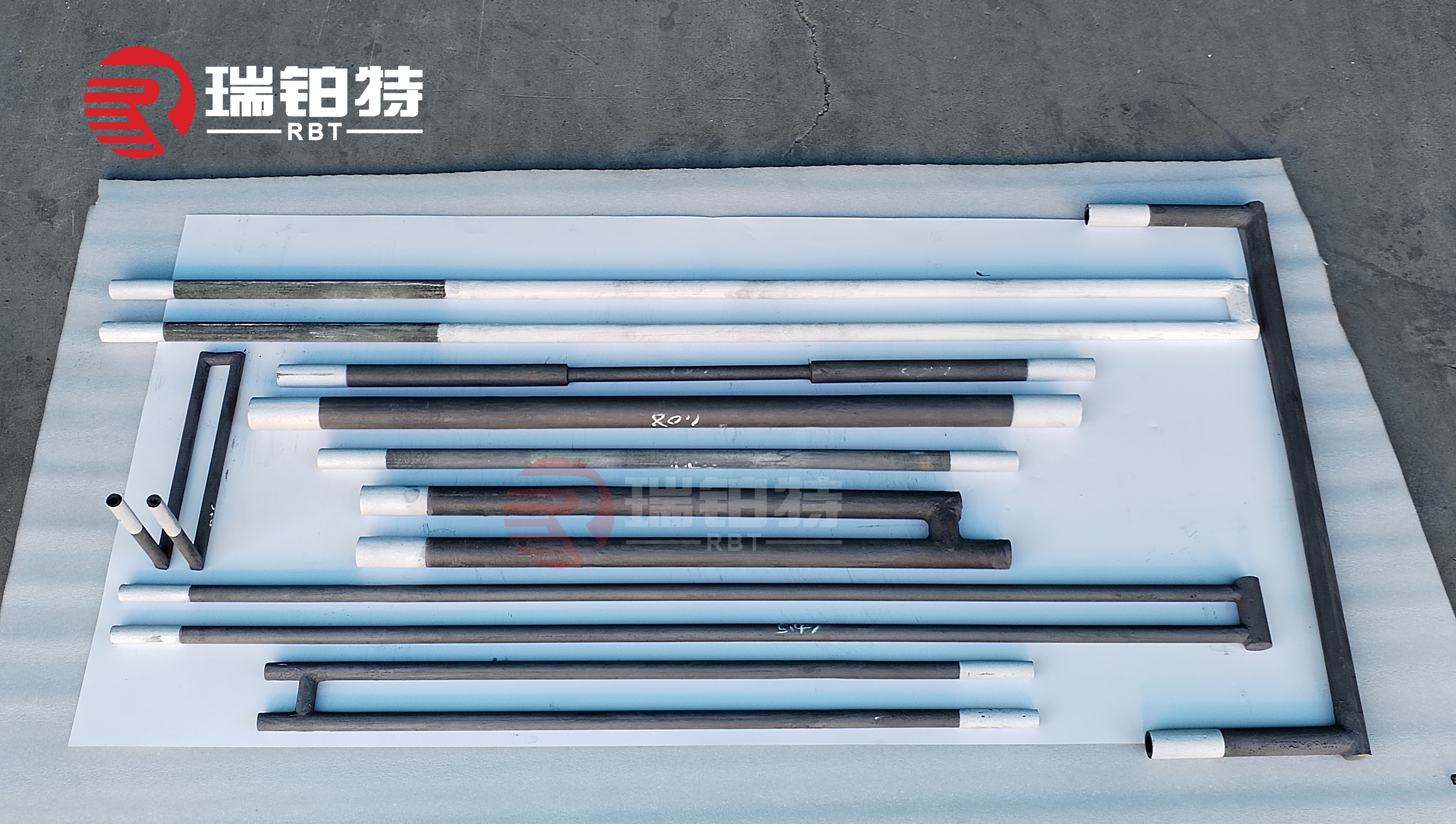

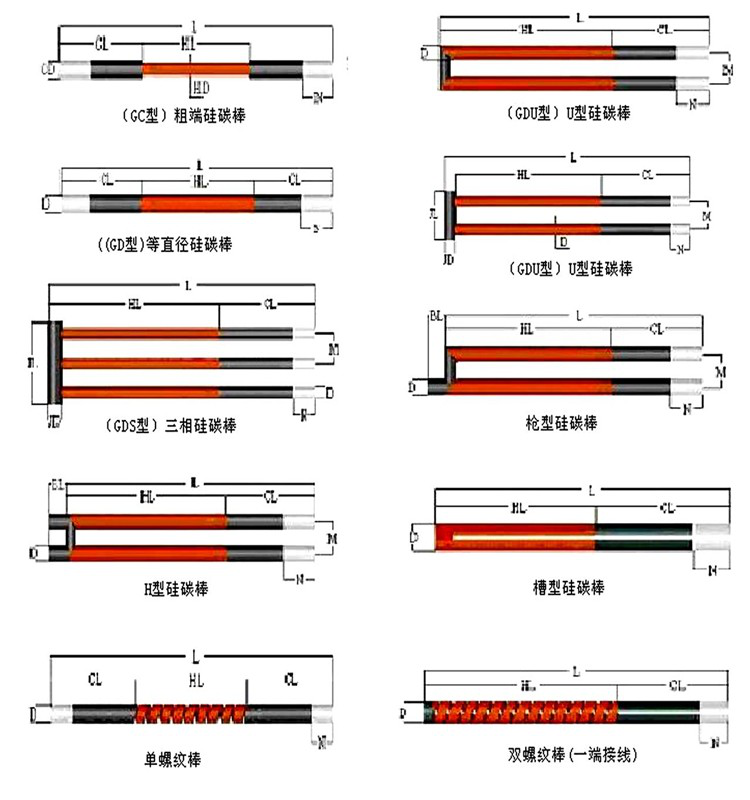

| Mohlala | GD(Molamu o lekanang oa bophara); GC (Molamu oa ho qetela oa Butt); GDC (thupa e bōpehileng joaloka U); GDQ (thupa ea mofuta oa sethunya);GDH (molamu oa mofuta oa H); Spiral; Lekhutlo le Le letona; Mofuta oa Heke |

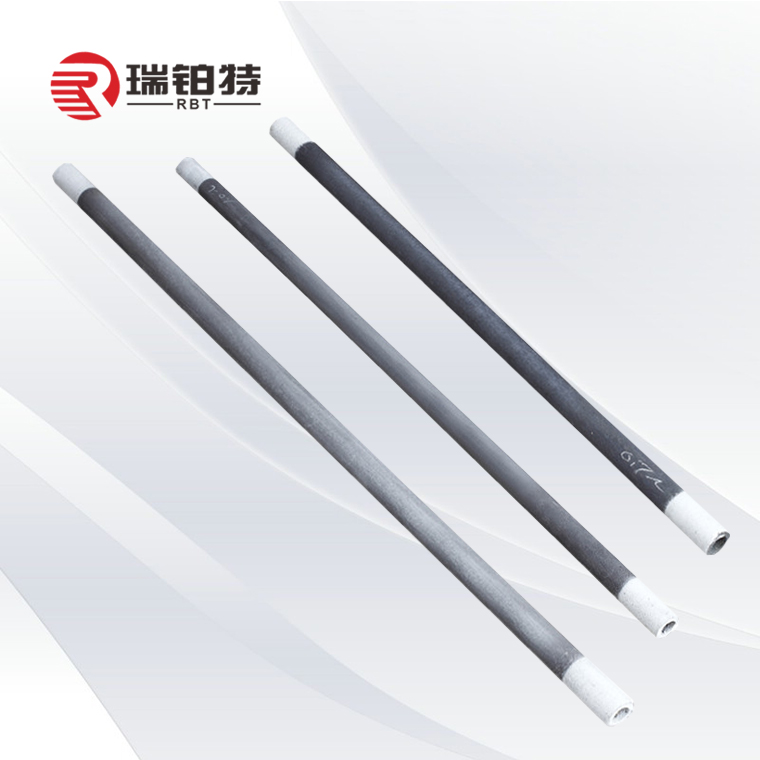

GD (Equal Diameter Silicon Carbide Rod)

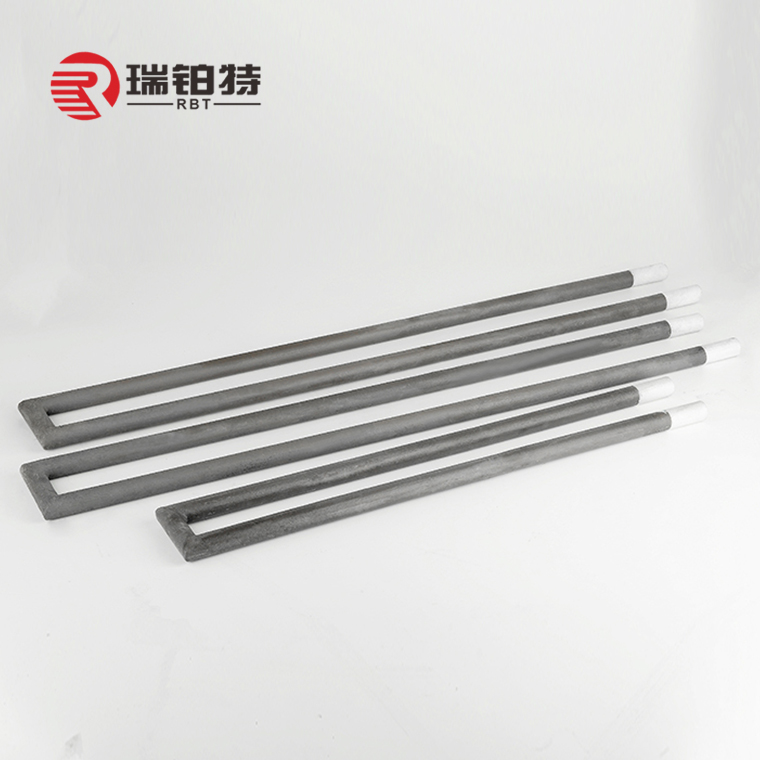

GDC (U-shaped Silicon Carbide Rod)

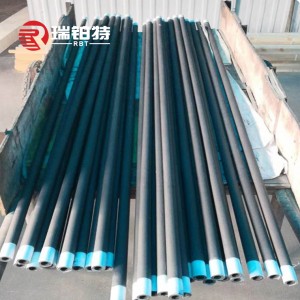

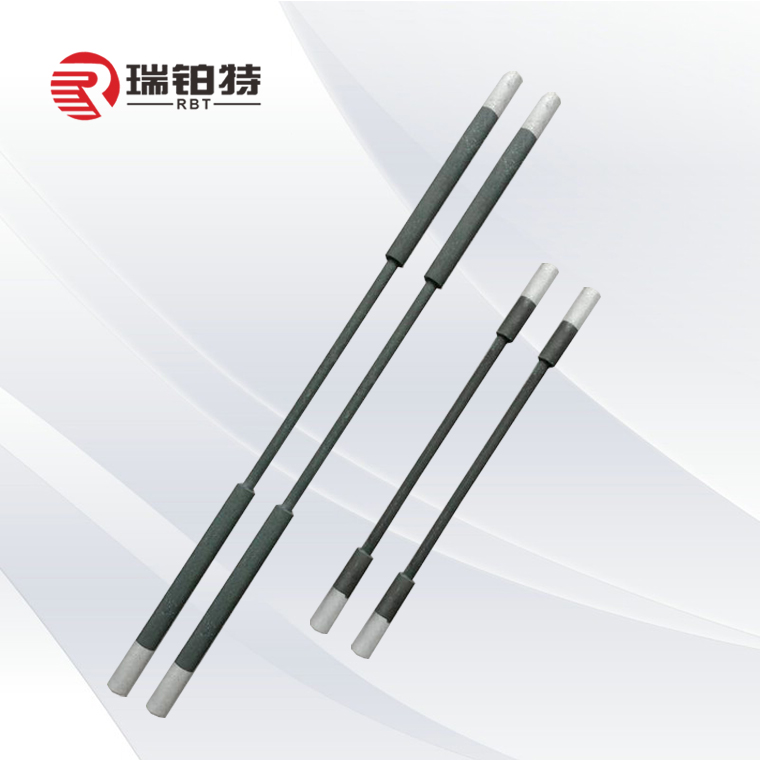

GC (Dumbbell Silicon Carbide Rod)

Right Angle Silicon Carbide Rod

GDQ (Sethunya sa Mofuta oa Silicon Carbide Rod)

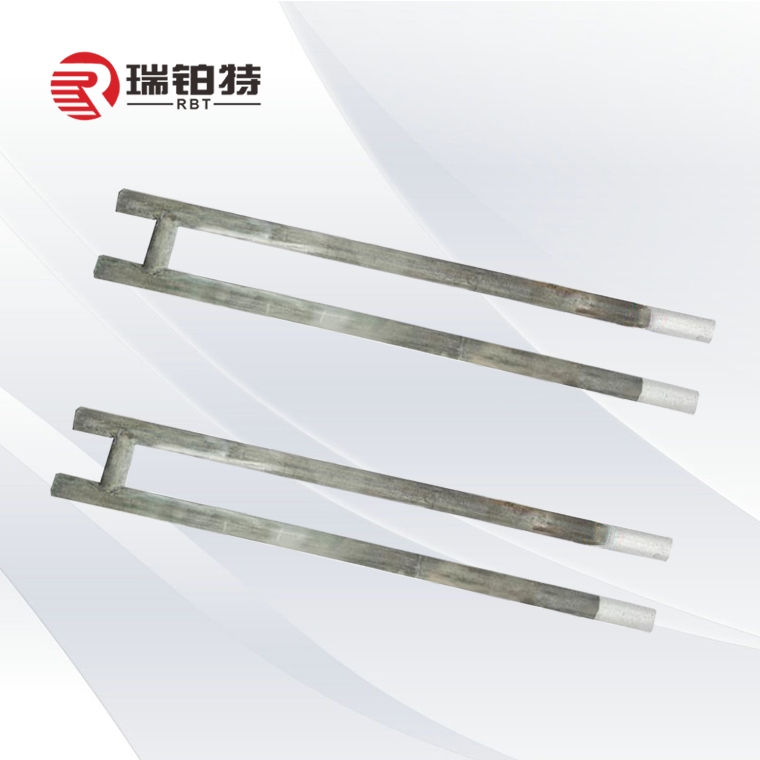

GDH (H-mofuta oa Silicon Carbide Rod)

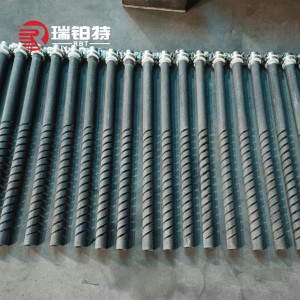

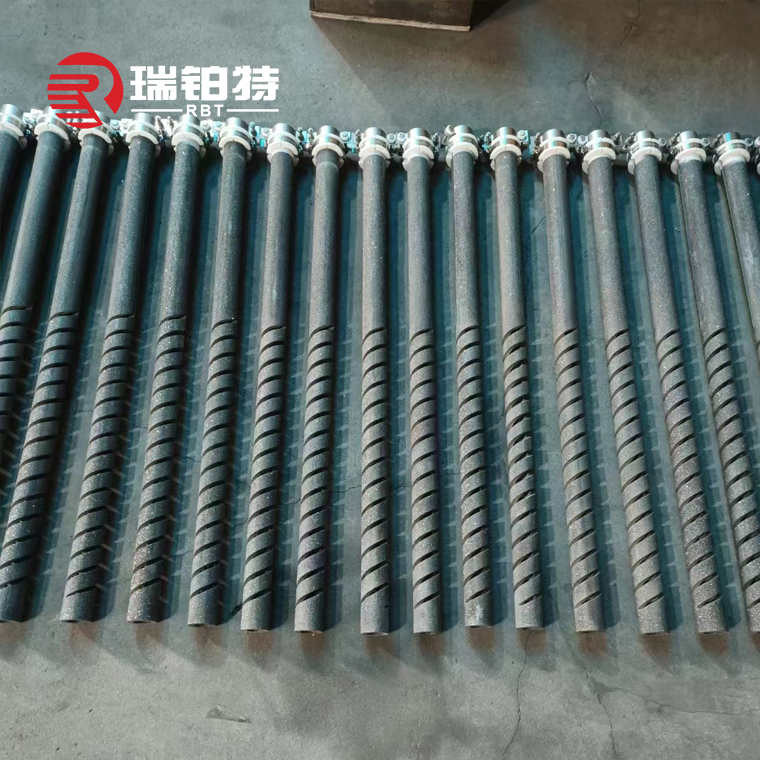

Spiral Silicon Carbide Rod

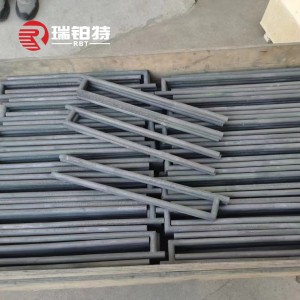

Mofuta oa Heke oa Silicon Carbide Rod

E ka Customized Ho ea ka Customer's Size Litlhokahalo

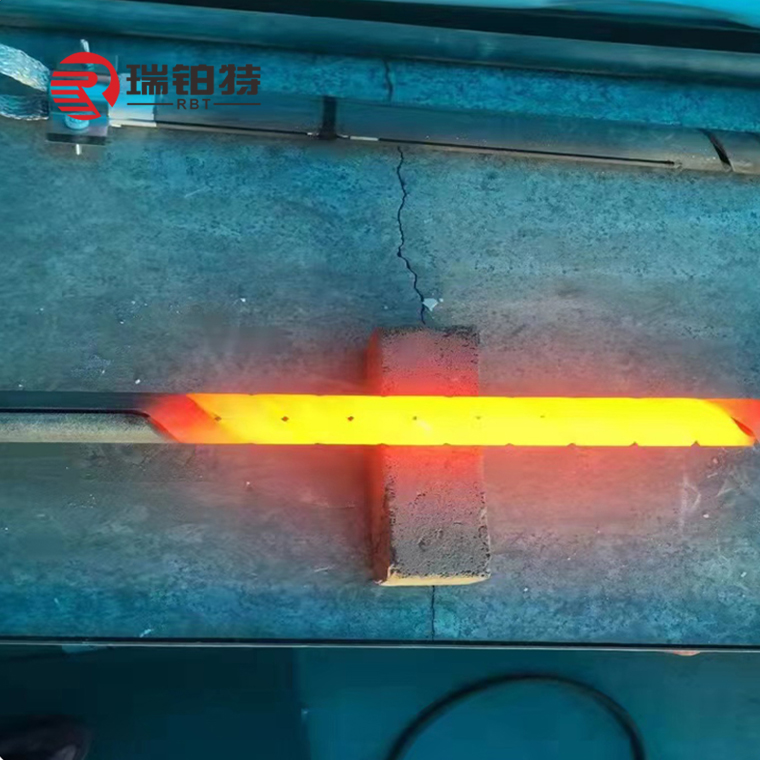

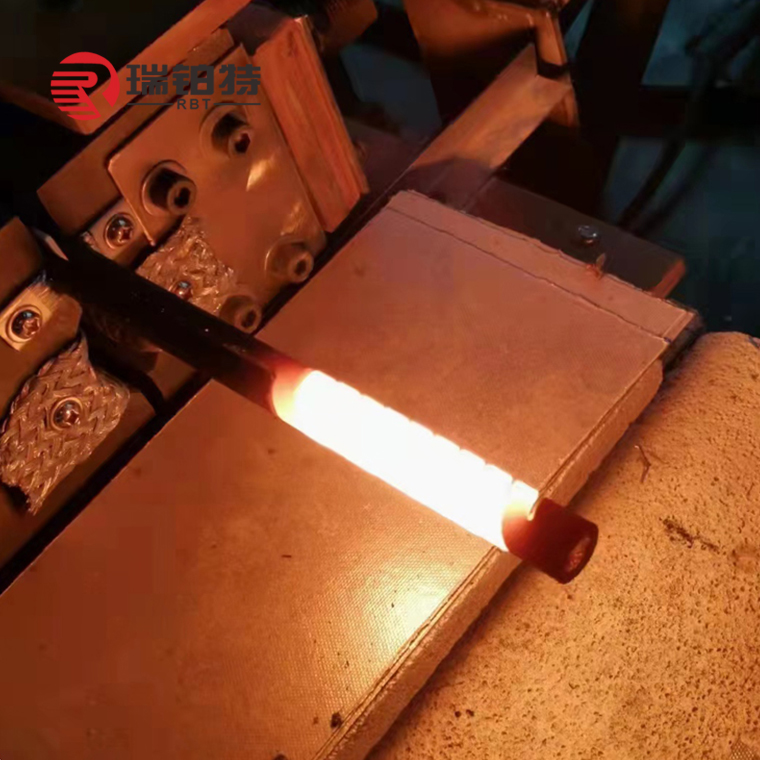

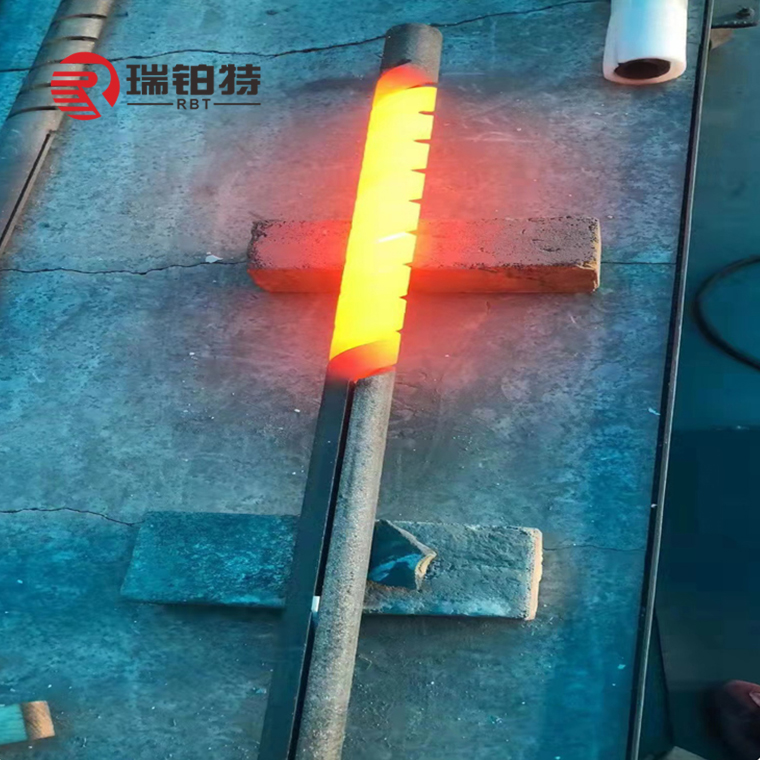

Pontšo ea Phello

Index ea Lihlahisoa

| Ntho | Yuniti | Letsatsi |

| Litaba tsa SiC | % | 99 |

| Litaba tsa SiO2 | % | 0.5 |

| Litaba tsa Fe2O3 | % | 0.15 |

| Litaba tsa C | % | 0.2 |

| Botenya | g/cm3 | 2.6 |

| Porosity e bonahalang | % | <18 |

| Matla a Hanyetsang Khatello | Mpa | ≥120 |

| Matla a Kobehang | Mpa | ≥80 |

| Mocheso oa ho sebetsa | ℃ | ≤1600 |

| Coefficient ea Katoloso ea Thermal | 10 -6/℃ | <4.8 |

| Thermal Conductivity | J/Kg℃ | 1.36*10 |

Kopo

Sebopi sa motlakase sa indasteri le sebopi sa liteko sa motlakase:Lithupa tsa carbon tsa silicon hangata li sebelisoa liindastering tsa mocheso tse mahareng le tse phahameng le libopi tsa liteko tsa motlakase. Li na le litšenyehelo tse tlase ebile li loketse masimo a indasteri a mocheso o phahameng joalo ka lirafshoa, likhalase le lisebelisoa tsa refractory. "

Indasteri ea khalase:Lithupa tsa khabone tsa silicon li sebelisoa haholo litankang tsa khalase tse phaphametseng, libopi tsa khalase ea optical, le ts'ebetso e tebileng ea likhalase. "

Metallurgy le lisebelisoa tsa refractory:Ka metallurgy ea phofo, li-phosphors tsa lefats'e tse sa tloaelehang, lisebelisoa tsa elektroniki, lisebelisoa tsa makenete, ho lahlela ka nepo le liindasteri tse ling, lithupa tsa silicon tsa khabone hangata li sebelisoa ka har'a libopi tsa li-push plate, libono tsa mabanta a marang-rang, libono tsa trolley, libopi tsa mabokose le lisebelisoa tse ling tsa ho futhumatsa. "

Libaka tse ling tsa mocheso o phahameng:Lithupa tsa khabone tsa silicon li boetse li sebelisoa liipone tsa kotopo, liipone tsa roller, libopi tsa vacuum, libopi tsa muffle, libopi tsa ho qhibilihisa le lisebelisoa tse fapaneng tsa ho futhumatsa, tse loketseng linako tseo ho tsona ho hlokahalang taolo e nepahetseng ea mocheso.

Sebopi sa motlakase sa indasteri le sebopi sa liteko sa motlakase

Indasteri ea khalase

Metallurgy le lisebelisoa tsa refractory

Libaka tse ling tsa mocheso o phahameng

Feme ea Rona

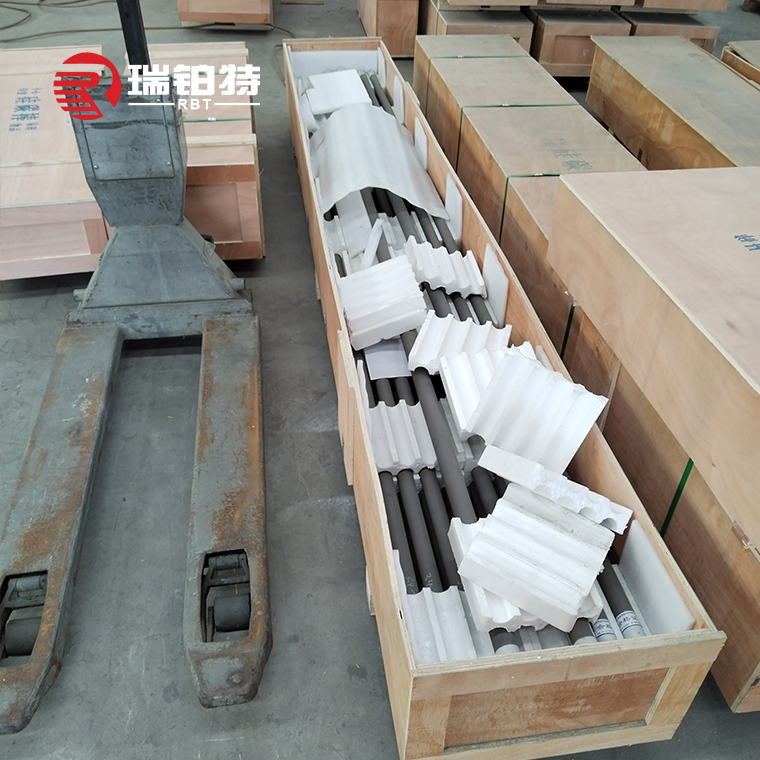

Sephutheloana le Bobolokelo

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e fumaneha motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa ea refractory. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea sebōpi, thekenoloji, le thepa ea ho rekisa kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a matla a tekheniki, boleng bo botle ba sehlahisoa le botumo bo botle. Feme ea rona e na le lihekthere tse fetang 200 mme tlhahiso ea selemo le selemo ea thepa e bōpehileng joaloka lithane tse ka bang 30000 'me thepa ea refractory e sa bopehang ke lithane tse 12000.

Lihlahisoa tsa rona tsa mantlha tsa thepa ea refractory li kenyelletsa:lisebelisoa tsa alkaline refractory; lisebelisoa tsa aluminium silicon refractory; thepa e sa bōpehang refractory; lisebelisoa tse thibelang mocheso oa mocheso; thepa e khethehileng refractory; lisebelisoa tse sebetsang tsa refractory bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Hangata

U hloka thuso? Etsa bonnete ba hore u etela liforomo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, feme ea rona e khethehile ho hlahisa thepa ea refractory ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ka mor'a ho rekisa.

Bakeng sa ts'ebetso e 'ngoe le e' ngoe ea tlhahiso, RBT e na le tsamaiso e feletseng ea QC bakeng sa metsoako ea lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa,' me setifikeiti sa boleng se tla romelloa ka thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho itšetlehile ka bongata, nako ea rona ea ho fana e fapane. Empa re tšepisa ho romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ha e le hantle, re fana ka mehlala ea mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e molemohali ho latela boemo ba hau.

Re 'nile ra etsa thepa ea refractory ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le phihlelo e ruileng, re ka thusa bareki ho rala li-kilns tse fapaneng le ho fana ka ts'ebeletso e le 'ngoe.