Mosi2 Heating Element

Tlhahisoleseding ya Sehlahiswa

Mosi2 futhumatsang elementke mofuta oa ntho e futhumatsang ea ho hanyetsa ha e le hantle e entsoeng ka Molybdenum Disilicide e hloekileng haholo. Sebakeng se nang le oxidizing, ho thehoa filimi e sireletsang ea quartz holim'a Mosi2 ka lebaka la mocheso o phahameng oa mocheso, o thibelang Mosi2 ho tsoela pele ho oxidizing. Sebakeng sa oxidizing, mocheso oa eona o phahameng o ka fihla ho 1800'C, 'me mocheso oa eona o sebetsang ke 500- 1700'C. E ka sebelisoa haholo lits'ebetsong tse kang sintering le kalafo ea mocheso ea ceramics, makenete, khalase, metallurgy, refractory, joalo-joalo.

Likaroloana:

1. Ts'ebetso e ntle ea mocheso o phahameng

2. Khanyetso e matla ea oxidation

3. Matla a phahameng a mochine

4. Lintho tse ntle tsa motlakase

5. Khanyetso e matla ea kutu

Lintho Tsa 'Mele

| Boima ba Molumo | Koba Matla | Vickers-Hadness |

| 5.5-5.6kg/cm3 | 15-25kg/cm2 | (HV)570kg/mm2 |

| Porosity Rate | Ho monya ha Metsi | Hot Extensiblity |

| 7.4% | 1.2% | 4% |

Lintlha Litšoantšo

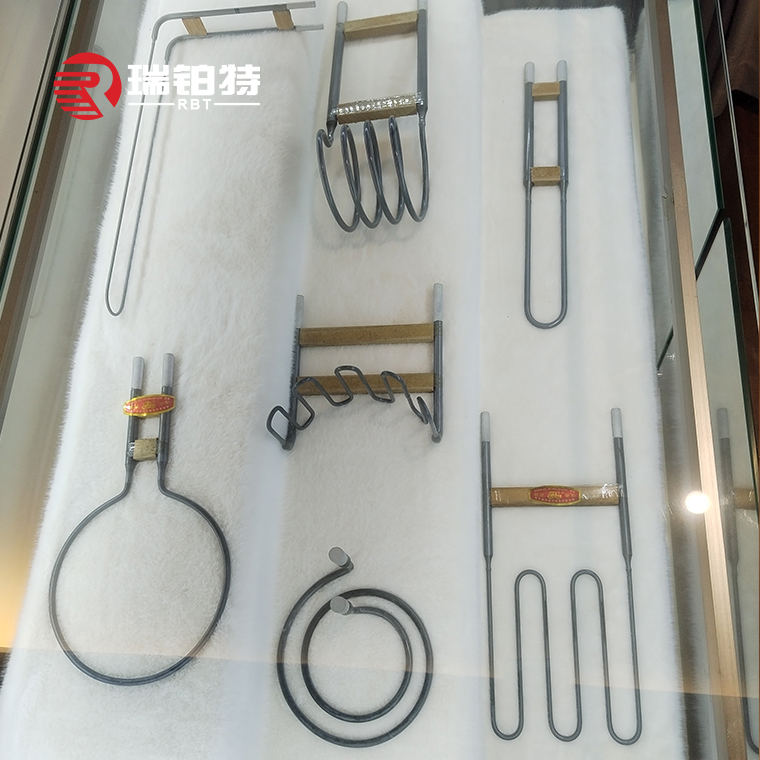

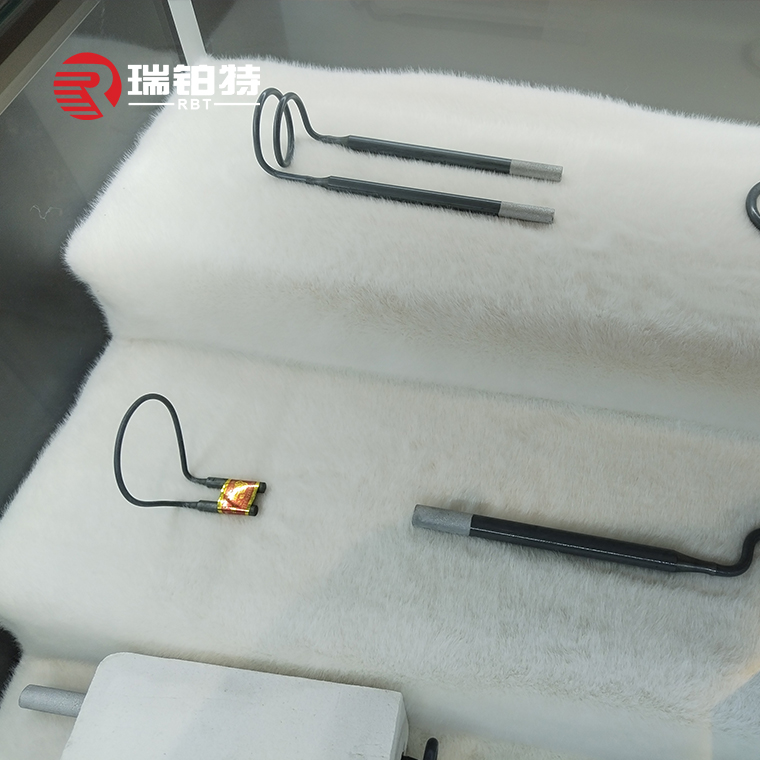

"Molamu oa silicon molybdenum o nang le sebopeho sa U:Ena ke e 'ngoe ea libopeho tse sebelisoang haholo. Moqapi o nang le matsoho a mabeli o etsa hore o sebelisoe haholo ka har'a libopi tsa motlakase tse nang le mocheso o phahameng oa mocheso 'me hangata o sebelisoa ho emisa ho otloloha. "

Thupa ea silicon ea molybdenum e lehlakoreng le letona:E loketse lisebelisoa tsa ho futhumatsa tse hlokang mohaho o nepahetseng. "

Ke mofuta oa silicon molybdenum rod:E loketse litlhoko tsa mocheso oa mohala.

"

W-mofuta oa silicon molybdenum rod:E loketse libaka tse hlokang ho futhumatsa ka maqhubu. "

Molamu oa silicon molybdenum o nang le sebōpeho se khethehileng:Ho kenyelletsa libopeho tse pota-potileng, tse chitja le tse ngata-ngata, joalo-joalo, tse loketseng litlhoko tsa ho futhumatsa tsa libopeho tse khethehileng.

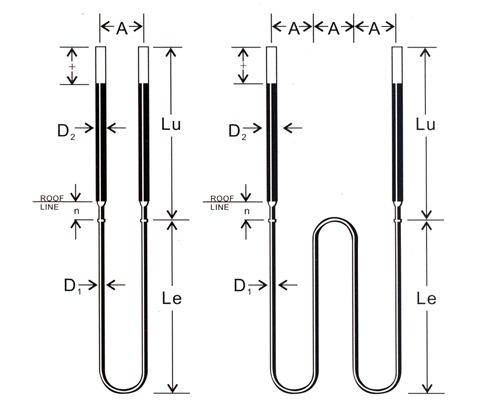

Standard Diameter Size Bakeng sa MoSi2 Muffle Furnace Heating Element

Mofuta oa M1700 (d/c):dia3/6, dia4/9, dia6/12, dia9/18, dia12/24 Mofuta oa M1800 (d/c):dia3/6, dia4/9, dia6/12, dia9/18, dia12/24(1) Le: Length of Hot Zone(2) Lu: Bolelele ba Cold Zone(3) D1: Diameter of Hot Zone(4) D2: Diameter of Cold Zone(5) A: Shank SpacingKa kopo, re tsebise lintlha tsena ha u reka odara ea sesebelisoa sa ho futhumatsa sebopi sa MoSi2 muffle.

| Diameter of Hot Zone | Diameter of Cold Zone | Bolelele ba Hot Zone | Bolelele ba Cold Zone | Sebaka sa Shank |

| 3mm | 6mm | 80-300 limilimithara | 80-500 limilimithara | 25 limilimithara |

| 4mm | 9mm | 80-350 limilimithara | 80-500 limilimithara | 25 limilimithara |

| 6mm | 12 limilimithara | 80-800 limilimithara | 80-1000 limilimithara | 25-60 limilimithara |

| 7mm | 12 limilimithara | 80-800 limilimithara | 80-1000 limilimithara | 25-60 limilimithara |

| 9mm | 18mm | 100-1200 limilimithara | 100-2500 limilimithara | 40-80 limilimithara |

| 12 limilimithara | 24 limilimithara | 100-1500 limilimithara | 100-1500 limilimithara | 40-100 limilimithara |

Phapang Pakeng tsa 1800 le 1700

(1) Lenonyeletso la tjheseletsa la 1800 silicon molybdenum rod le tletse, le hlahella le ho kokomoha, mme ha ho lepetso sebakeng sa welding, se fapaneng le mofuta wa 1700.

(2) Bokaholimo ba 1800 silicon molybdenum rod bo boreleli ebile bo na le khanya ea tšepe.

(3) Matla a khoheli a khethehileng a phahame. Ha ho bapisoa le mofuta oa 1700, 1800 silicon molybdenum rod ea litlhaloso tse tšoanang e tla ba boima le ho feta.

(4) Mmala o fapane. E le ho shebahala hantle, bokaholimo ba silicon molybdenum rod ea 1700 bo a phekoloa 'me bo shebahala bo batsho.

(5) Ts'ebetso ea hajoale le voltage ea 1800 silicon molybdenum rod li nyane ho feta tsa mofuta oa 1700. Bakeng sa karolo e ts'oanang e chesang ea 9, mochini o sebetsang oa mofuta oa 1800 ke 220A, 'me oa 1700 degree element e ka ba 270A.

(6) Mocheso o sebetsang o phahame, o fetang likhato tse 100 ho feta tsa 1700 degree.

(7) Likopo tse akaretsang:

Mofuta oa 1700: haholo-holo e sebelisoang liindastering tsa mocheso oa mocheso oa indasteri, libopi tsa sintering, libōpi tsa ho lahla, libōpi tse qhibilihisang likhalase, libōpi tse qhibilihisang, joalo-joalo.

Mofuta oa 1800: E sebelisoa haholo liboping tsa liteko, lisebelisoa tsa tlhahlobo le libopi tsa mocheso o phahameng oa mocheso, joalo-joalo.

| Thempereichara e Phahameng ea Element Libakeng tse Fapaneng | ||

| Sepakapaka | Max Element Mocheso | |

| Mofuta oa 1700 | Mofuta oa 1800 | |

| Moea | 1700 ℃ | 1800 ℃ |

| Naetrojene | 1600 ℃ | 1700 ℃ |

| Argon, Helium | 1600 ℃ | 1700 ℃ |

| Haedrojene | 1100-1450 ℃ | 1100-1450 ℃ |

| N2/H2 95/5% | 1250-1600 ℃ | 1250-1600 ℃ |

Kopo

Metallurgy:E sebelisoa ho qhibilihisa tšepe le ho hloekisoa ho thusa ho fumana ho qhibiliha ha mocheso o phahameng.

Ho Etsa Likhalase:E le sesebelisoa sa ho futhumatsa bakeng sa libopi tsa crucible tsa motlakase le libono tsa tanka ea letsatsi, e sebelisoa ho hlahisa lihlahisoa tsa khalase tsa boleng bo holimo.

Indasteri ea Ceramic:Netefatsa ho thunya ho tšoanang le tlhahiso ea boleng bo holimo ea lihlahisoa tsa ceramic ka libotlolong tsa ceramic.

Indasteri ea Elektronike:E sebelisetsoa ho etsa lisebelisoa tsa elektroniki tse nang le mocheso o phahameng oa mocheso le likarolo tse ling, joalo ka li-tubes tse sireletsang thermocouple.

Sepakapaka:E le karolo ea bohlokoa ea mekhoa ea ho futhumatsa le ho laola mocheso libakeng tse phahameng tsa mocheso.

Metallurgy

Khalase Manufacturing

Indasteri ea Ceramic

Indasteri ea Elektronike

Sephutheloana le Bobolokelo

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e sebakeng sa Zibo City, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea lintho tse refractory. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea sebōpi, thekenoloji, le thepa ea ho rekisa kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a matla a tekheniki, boleng bo botle ba sehlahisoa le botumo bo botle. Feme ea rona e na le lihekthere tse fetang 200 mme tlhahiso ea selemo le selemo ea thepa e bōpehileng joaloka lithane tse ka bang 30000 'me thepa ea refractory e sa bopehang ke lithane tse 12000.

Lihlahisoa tsa rona tsa mantlha tsa thepa ea refractory li kenyelletsa:lisebelisoa tsa alkaline refractory; lisebelisoa tsa aluminium silicon refractory; thepa e sa bōpehang refractory; lisebelisoa tse thibelang mocheso oa mocheso; thepa e khethehileng refractory; lisebelisoa tse sebetsang tsa refractory bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Hangata

U hloka thuso? Etsa bonnete ba hore u etela liforomo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, feme ea rona e khethehile ho hlahisa thepa ea refractory ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ka mor'a ho rekisa.

Bakeng sa ts'ebetso e 'ngoe le e' ngoe ea tlhahiso, RBT e na le tsamaiso e feletseng ea QC bakeng sa metsoako ea lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa,' me setifikeiti sa boleng se tla romelloa ka thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho itšetlehile ka bongata, nako ea rona ea ho fana e fapane. Empa re tšepisa ho romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ha e le hantle, re fana ka mehlala ea mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e molemohali ho latela boemo ba hau.

Re 'nile ra etsa thepa ea refractory ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le phihlelo e ruileng, re ka thusa bareki ho rala li-kilns tse fapaneng le ho fana ka ts'ebeletso e le 'ngoe.