Lisebelisoa tsa Alumina Lining

Catalog ea Lihlahisoa

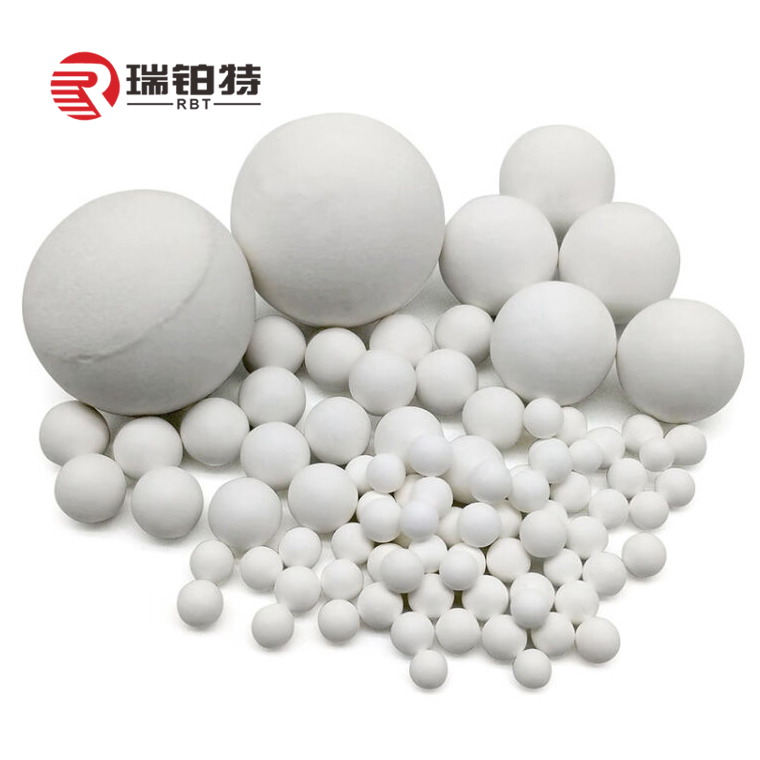

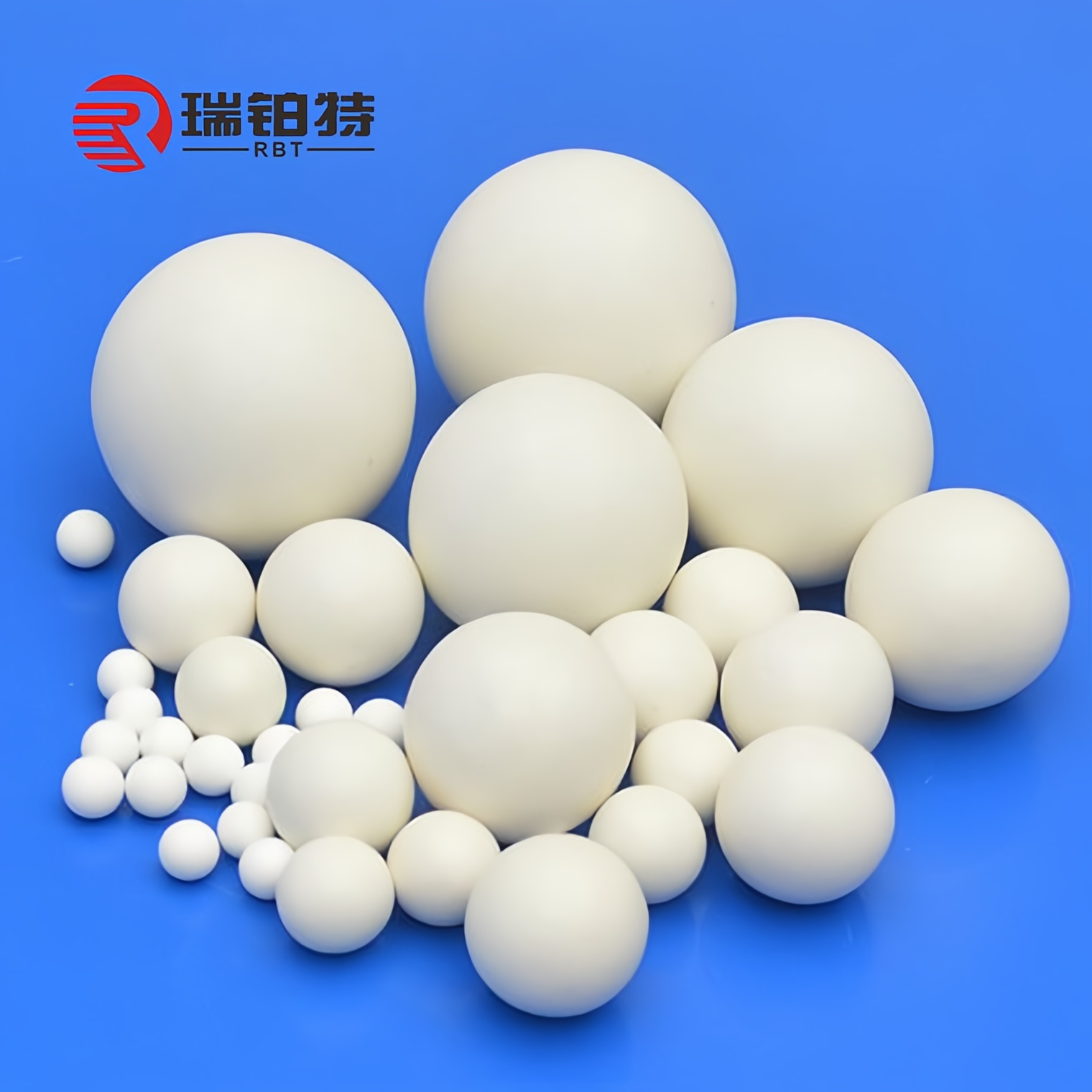

1. Alumina Ball

(1) Alumina libolo tsa ceramicke lisebelisoa tse phahameng tsa ts'ebetso tse se nang tšepe tse nang le aluminium oxide (Al2O3) e le karolo ea mantlha.

Likaroloana:

Khanyetso e phahameng ea ho apara; Ho hanyetsa mocheso o phahameng; Ho hanyetsa kutu; boima bo phahameng; Matla a phahameng a hatellang; Thermal stability e ntle

Kopo:

Tšehetso ea Catalyst le tower filler:Ka setsing sa motlakase, libolo tsa alumina ceramic li sebelisoa e le lisebelisoa tse koahelang ts'ehetso le li-filler tsa tora ho eketsa libaka tsa kabo ea khase kapa metsi ho ntlafatsa ts'ebetso ea karabelo le ho sireletsa sesebelisoa se sebetsang ka matla a tlase. "

Media ea ho sila:E sebelisoa haholo lisebelisoa tsa ho sila tse ntle joalo ka litšilo tsa bolo le li-vibrate ho sila lirafshoa, li-slurries, lisebelisoa tse sa senyeheng, le phofo e kang lipente le lipente. Ho hanyetsa ha eona ho khabane le ho pota-pota ho ka qoba likhopo nakong ea ho bentša le ho kopana ka botlalo le ntho ea ho bentša. "

Lisebelisoa tse ling:E boetse e sebelisoa haholo liindastering tse ngata tse kang li-petrochemicals, li-ceramics tsa bohloeki, liminerale tse seng tsa tšepe, tšepe le lisebelisoa tsa elektroniki.

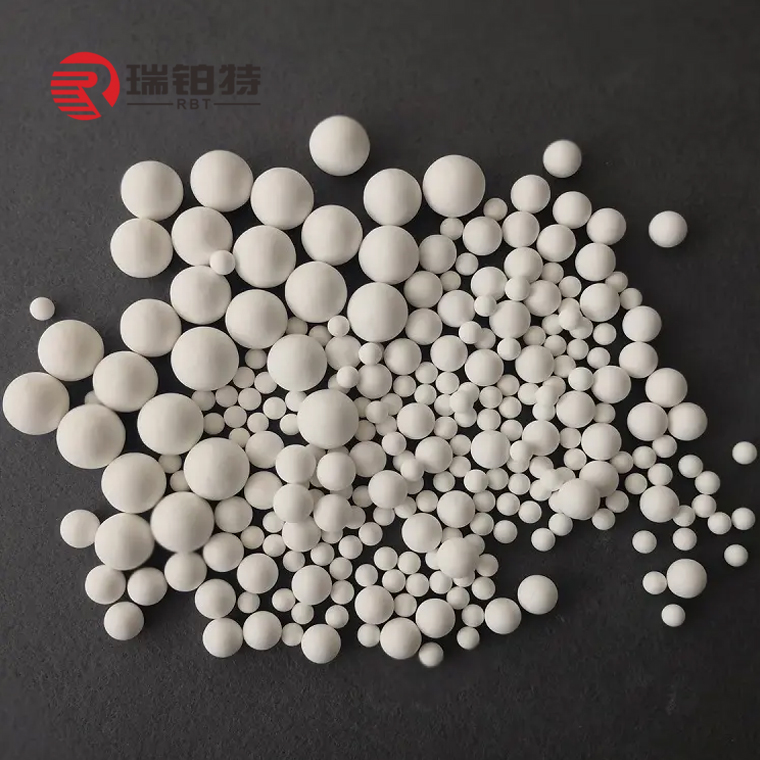

"(2) Alumina e silang boloke mofuta oa mokhoa oa ho sila o entsoeng ka bauxite, phofo ea rolara, phofo ea alumina ea indasteri, joalo-joalo, ka ho kopanya, ho sila, ho etsa phofo, ho bōpa, ho omisa, ho sila le mekhoa e meng. Karolo ea eona e ka sehloohong ke α-Al2O3, e nang le litšobotsi tsa boima bo phahameng, khanyetso e phahameng ea ho apara le botsitso ba lik'hemik'hale, 'me e sebelisoa haholo mekhoeng e sa tšoaneng ea ho sila le ho bentša.

Kopo:

Indasteri ea Ceramic le khalase:e sebelisetsoang ho sila glaze le phofo ea ceramic ho ntlafatsa ho tšoana le ho fela ha sehlahisoa. "

Indasteri ea ho roala:e sebelisetsoang ho sila le ho qhala litlolo tse entsoeng ka metsi le tse entsoeng ka oli ho ntlafatsa mokelikeli le ho khomarela liphahlo. "

Indasteri ea elektronike:e sebelisetsoang ho sila likarolo tsa mochine o nepahetseng le likarolo tsa optical ho netefatsa ho nepahala ho phahameng le boleng bo botle ba holim'a metsi. "

Lisebelisoa tse ncha tsa matla:e sebelisetsoang ho sila lisebelisoa tsa betri ea lithium ho khothaletsa kabo e tšoanang le ntlafatso ea ts'ebetso ea lisebelisoa. Tšireletso ea Tikoloho: e sebelisetsoa ho hloekisa metsi a litšila le ho felloa ke metsi 'meleng ho tlosa litšila le litšila metsing.

Boholo ba likaroloana:0.3-0.4, 0.4-0.6, 0.6-0.8, 0.8-1.0, 1.0-1.2, 1.2-1.4, 1.4-1.6, 1.8-2.0, 2.0-2.2, 2.2-2.4, 2.8-2-3.3. 4.5-5.0, 5.0-5.5, 6.0-6.5, 6.5-7.0, 8, 10, 12, 15, 20

Alumina Grinding Balls

Alumina Ceramic Balls

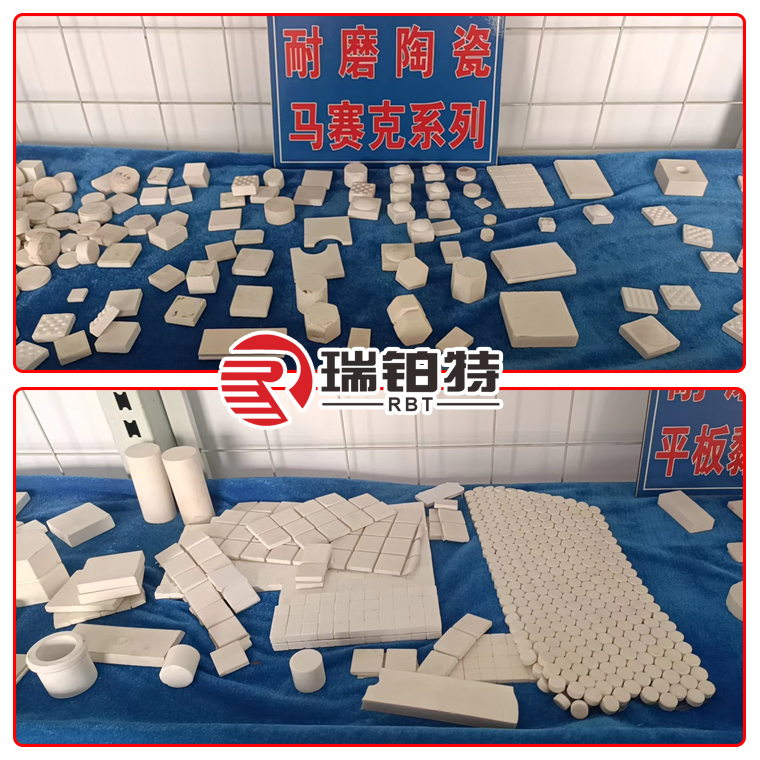

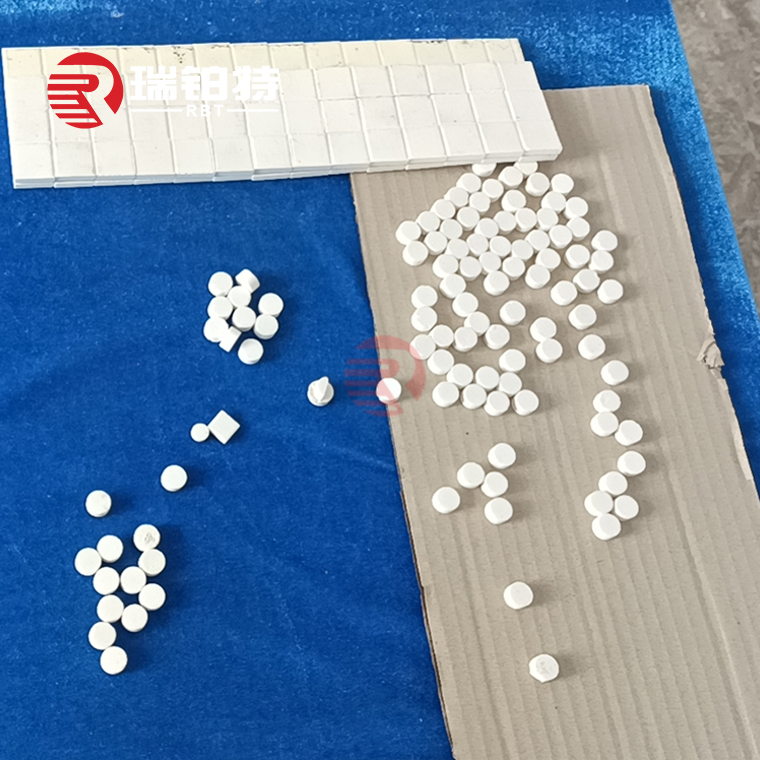

2. 92%, 95% Alumina Wear-resistant Ceramics(lihlahisoa tse tloaelehileng, tse nang le sebōpeho se khethehileng, tse ikhethileng)

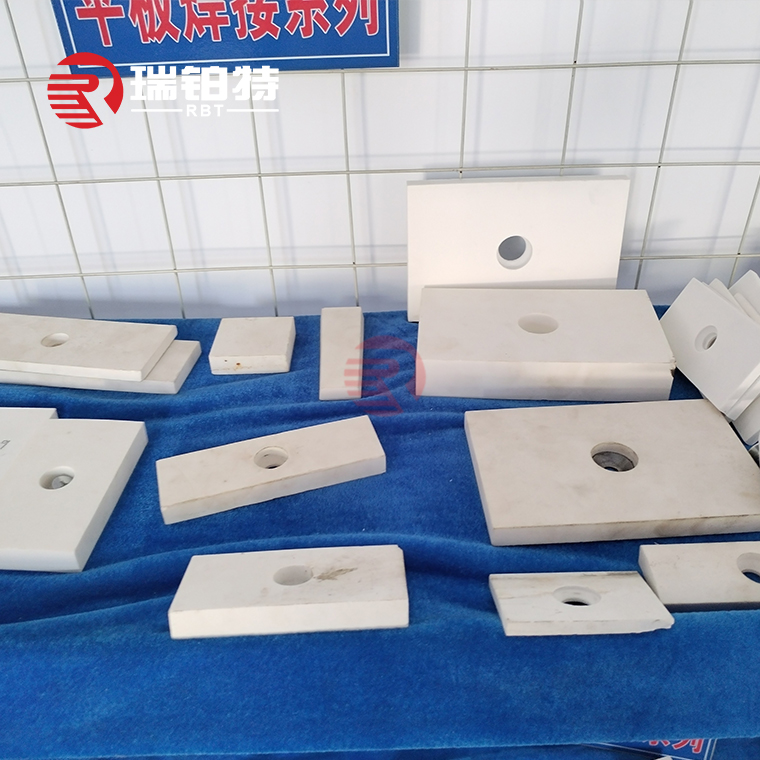

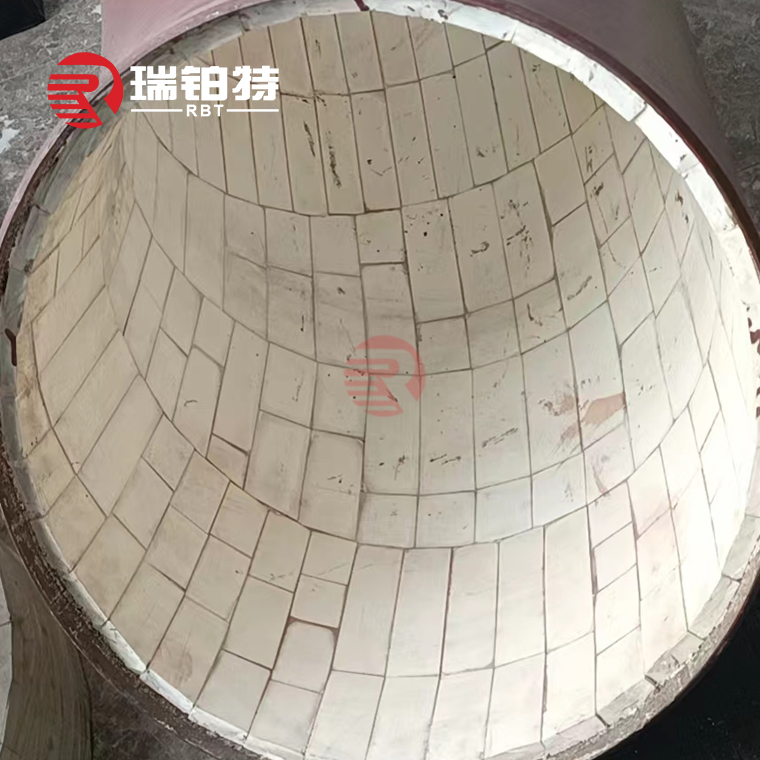

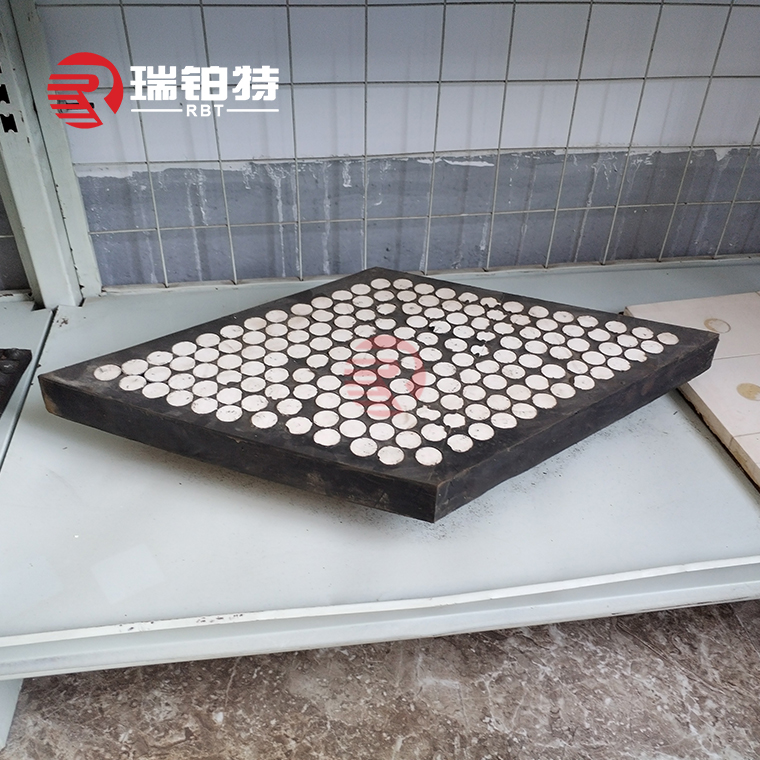

(1) Mosaic oa ceramic o manganga lithaeleke lisebelisoa tsa ceramic tse sebetsang hantle, haholo-holo tse entsoeng ka lisebelisoa tsa ceramic tse matla tse kang alumina le silicon nitride. Sebaka se ka holimo se tšoaroa ka mekhoa e khethehileng 'me se na le boima bo phahameng ka ho fetisisa le ho hanyetsa ho apara. Ts'ebetso ea eona ea tlhahiso e kenyelletsa mahlale a tsoetseng pele joalo ka khatello e omileng le grouting, mme litlhaloso li fapane

ho fihlela litlhoko tsa lits'ebetso tse fapaneng tsa indasteri.

Likaroloana:

1. Ho thatafala ho phahameng:The Rockwell hardness of wear-resistant ceramic mosaic e fihla ho HRA80-90, ea bobeli ho daemane, 'me e na le boima bo phahameng haholo le ho hanyetsa ho apara.

2. Rear resistance:Ho hanyetsa ha eona ho lekana le makhetlo a 266 a tšepe ea manganese le makhetlo a 171.5 ho feta a tšepe e phahameng ea chromium, e bontšang ho hanyetsa.

3. Boima bo bobebe:The density ke 3.6g/cm³, e leng halofo feela ea tšepe, e ka fokotsang boima ba lisebelisoa haholo le ho ntlafatsa ts'ebetso ea sesebelisoa.

4. Kaho e bonolo:Mosaic ea ceramic e sa keneleng ho roala e bonolo ho e kenya le ho e hlokomela, ho fokotsa bothata le litšenyehelo tsa kaho.

Kopo:

Indasteri ea peterole:e sebelisoa e le likarolo tse sa sebetsaneng le li-reactors, liphaephe, 'mele oa pompo le lisebelisoa tse ling, e lelefatsa bophelo ba lisebelisoa haholo le ho ntlafatsa polokeho.

Merafo le metallurgy:ho ntlafatsa haholo ho hanyetsa ho apara le katleho ea tlhahiso likarolong tsa ho apara tsalisebelisoa tse joalo ka litšilo tsa bolo, litsi tsa mashala, le mechini ea ho hula. "

Indasteri ea matla a motlakase:e sebelisoang likarolong tse sa sebetsaneng tsa ho fehla matla a mashala, ho fehla matla a khase le lisebelisoa tse ling, tse kang li-burners, lifensetere tsa mashala le ba bokellang lerōle, ka katleho ho ntlafatsa bophelo ba tšebeletso le ho sebetsa hantle ha lisebelisoa. "

Ho etsa mechine:e sebelisetsoang ho etsa likarolo tsa boleng bo phahameng, tse sa apareng haholo, joalo ka li-bearing, likere, le liporo tsa tataiso, ho ntlafatsa haholo ts'ebetso le ts'epahalo ea lihlahisoa tsa mochini.

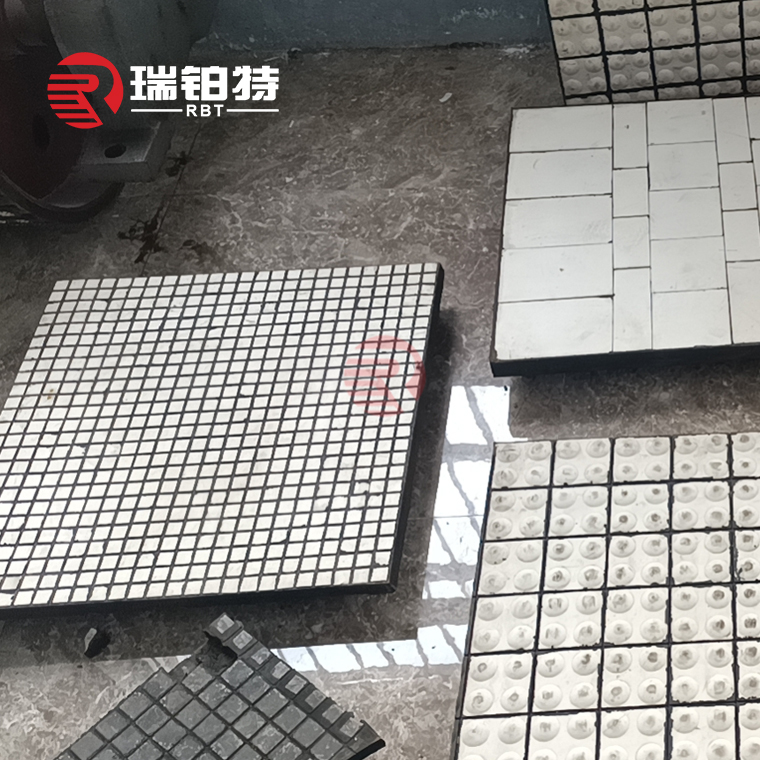

(2) Litene tsa lesela la ceramic tse sa senyehenghangata li entsoe ka motsoako oa lisebelisoa tsa ceramic le lisebelisoa tsa matrix. Lisebelisoa tsa ceramic hangata li sebelisa lirafshoa tse phahameng tsa alumina kapa li-ceramics tsa zirconia, tse nang le khanyetso e ntle ea ho roala le matla a khatello. Hangata thepa ea matrix ke tšepe kapa lisebelisoa tse ling tsa tšepe, tse fanang ka tšehetso e hlokahalang le ho tiea. Ka ho kopanya lera la ceramic le matrix a tšepe, ho thehoa thepa e kopantsoeng e sa senyeheng le e thata ka ho lekaneng.

Kopo:

Mechini ea merafo:Sireletsa lisebelisoa tsa ho sila le ho hlahlobisisa ho tsoa ho ore. "

Indasteri ea metallurgic:E sebelisoa liboping tsa mocheso o phahameng le lisebelisoa tsa ho lahlela ka lebaka la ho hanyetsa mocheso o phahameng haholo le ho hanyetsa kutu. "

Indasteri ea matla:E sebelisoa ho sireletsa lisebelisoa tsa ho tsamaisa phofo ea mashala le libono tsa boiler. "

Tlhahiso ea samente:Fokotsa kamano e tobileng pakeng tsa mabanta a conveyor le thepa le ho lelefatsa bophelo ba lisebelisoa. "

Indasteri ea lik'hemik'hale:E sebelisoa lisebelisoa tse kang li-ball Mills ho eketsa tlhahiso ea ho sila le ho fokotsa litšenyehelo tsa tšebeliso ea matla le tlhokomelo.

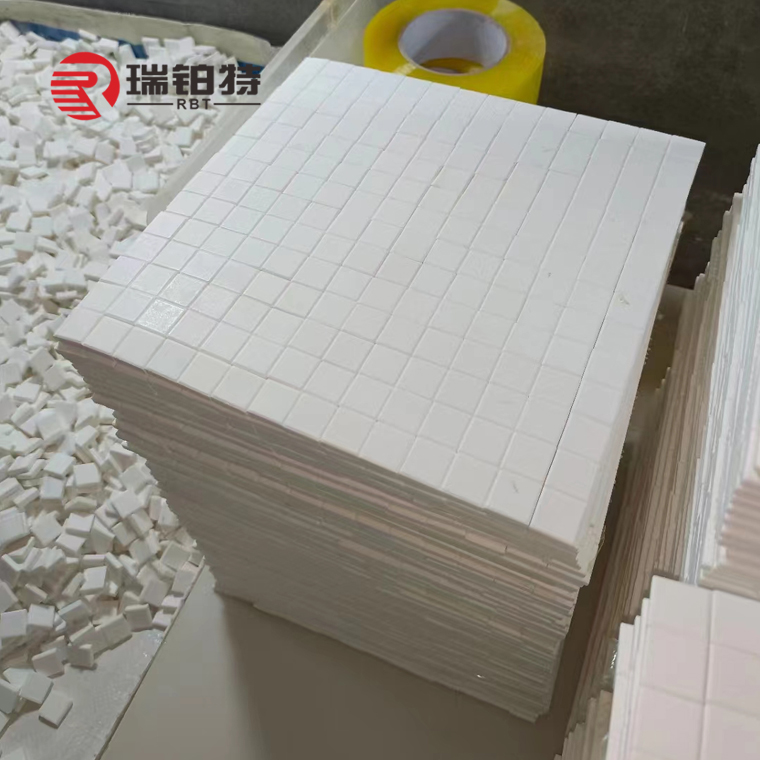

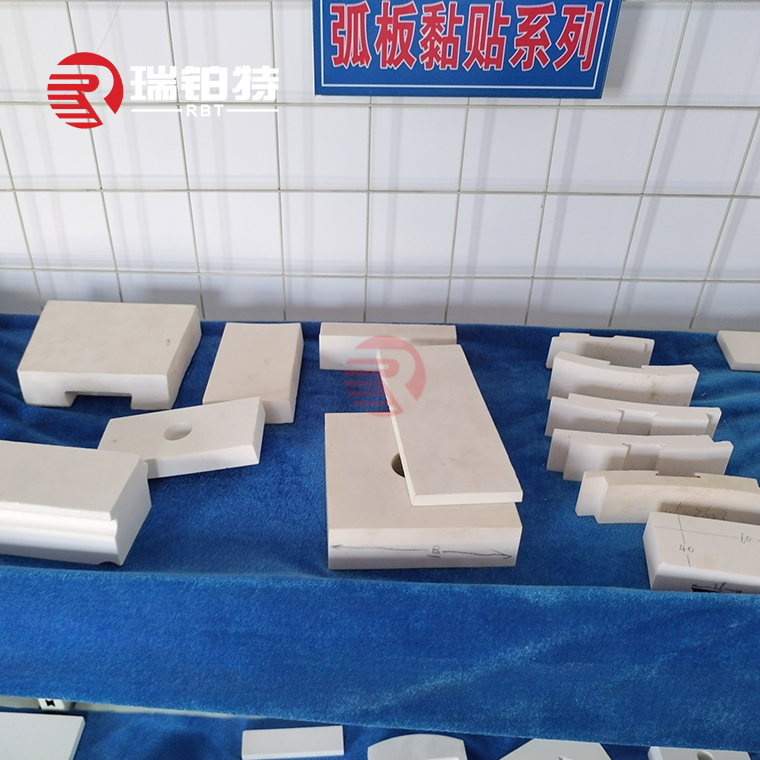

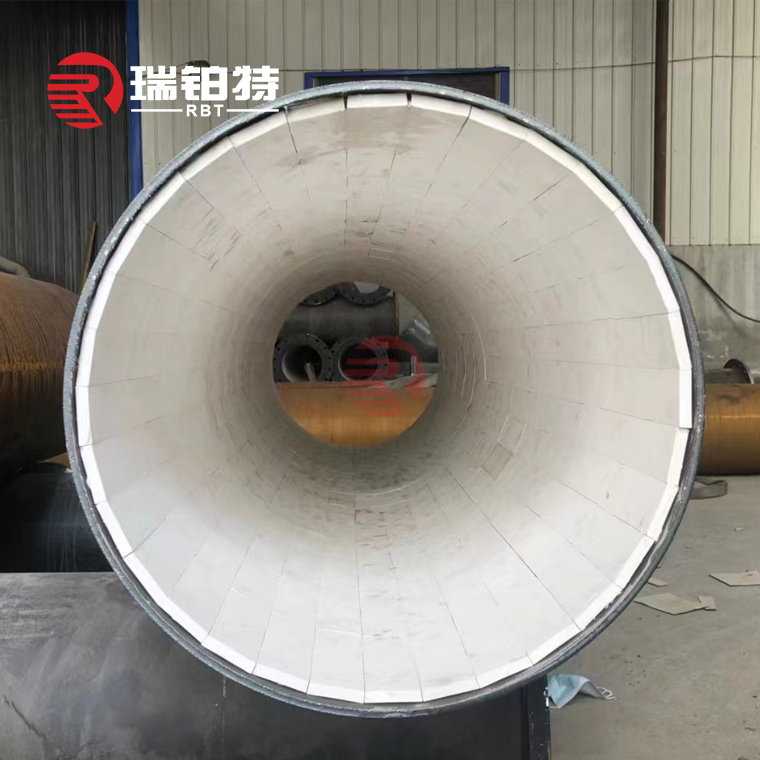

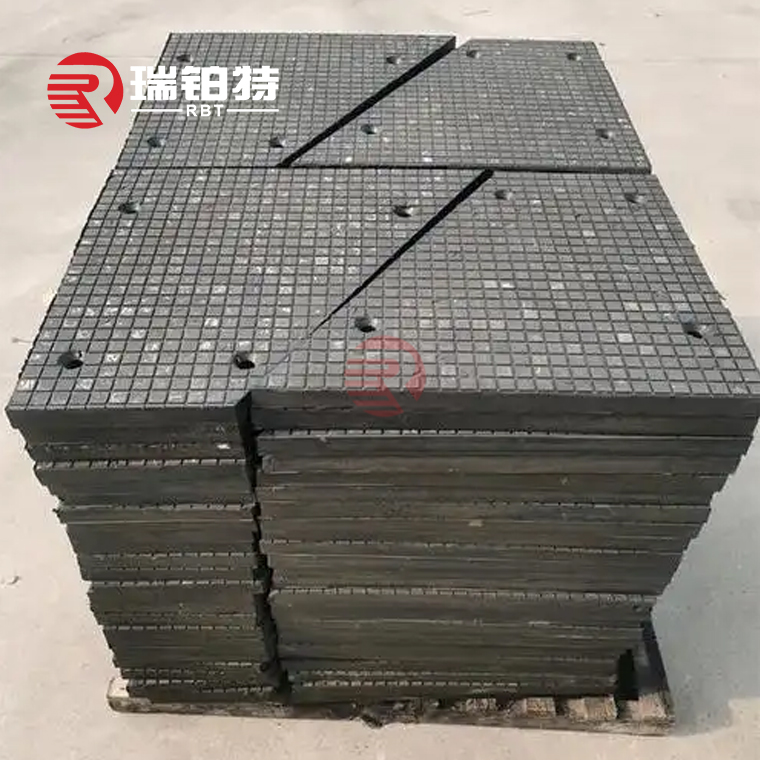

(3) Lesela la ceramic le sa keneng lipoleitike thepa e nang le alumina (AL2O3) e le 'mele o ka sehloohong, e tlatsitsoeng ka lisebelisoa tse ling,' me e sintered mocheso o phahameng oa 1700 ° C. E na le khanyetso e ntle ea ho roala, ho hanyetsa kutu le botsitso ba mocheso o phahameng, 'me e sebelisoa haholo ho tsamaisa mashala, lisebelisoa tsa ho tsamaisa thepa, lisebelisoa tsa ho etsa phofo, ho ntša molora, lisebelisoa tsa ho tlosa lerōle le lisebelisoa tse ling tsa mochine tse nang le matla a phahameng a mocheso, tšepe, metallurgy, mechine, mashala, meepo, lik'hemik'hale, samente, liteishene tsa koung le likhoebo tse ling.

Lisebelisoa:

Indasteri ea merafo:Nakong ea merafo, lisebelisoa li atisa ho angoa ke li-abrasives le liphello. Tšebeliso ea lesela la ceramic le sa sebetseng le ka lelefatsa bophelo ba lisebelisoa le ho fokotsa litšenyehelo tsa tlhokomelo.

Indasteri ea metallurgic:Lisebelisoa tsa metallurgical, lesela la ceramic le sa sebetseng le ka thibela khoholeho ea tšepe e qhibilihisitsoeng le ore ho netefatsa ts'ebetso e tsitsitseng ea lisebelisoa.

Indasteri ea lik'hemik'hale:Tlhahisong ea lik'hemik'hale, hangata lisebelisoa li pepesehetse mecha ea litaba e senyang. Tšebeliso ea lesela la ceramic le sa sebetseng le ka ntlafatsa ho tšoarella ha lisebelisoa le ho fokotsa ho hloleha ho bakoang ke kutu. "

Indasteri ea matla:Ka thepa ea matla, lirala tsa ceramic tse sa sebetseng li ka fokotsa ka nepo ho roala ha lerōle le likaroloana tse ling tse tiileng holim'a lisebelisoa, ho netefatsa ts'ebetso e tsitsitseng ea nako e telele ea lisebelisoa.

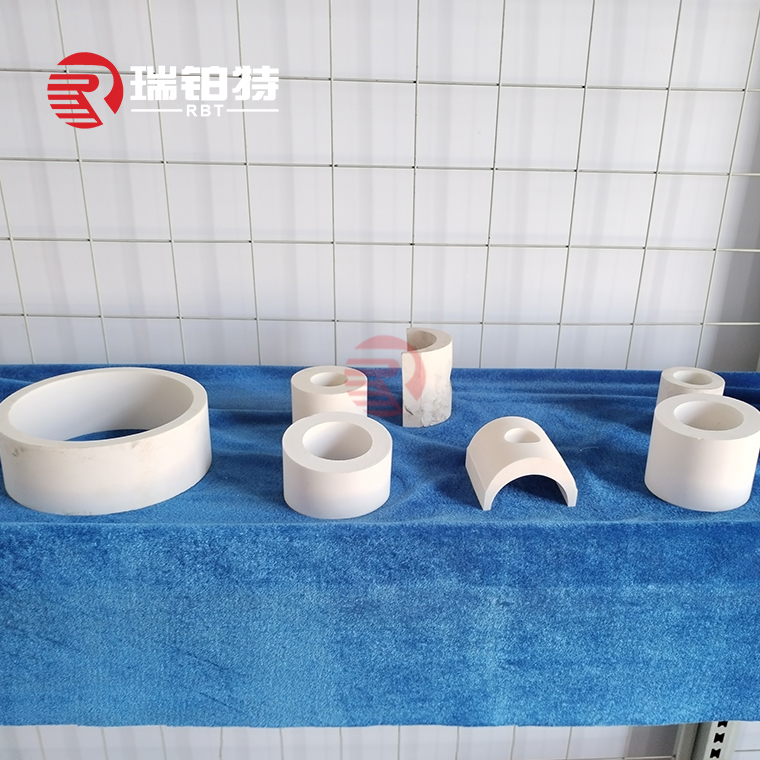

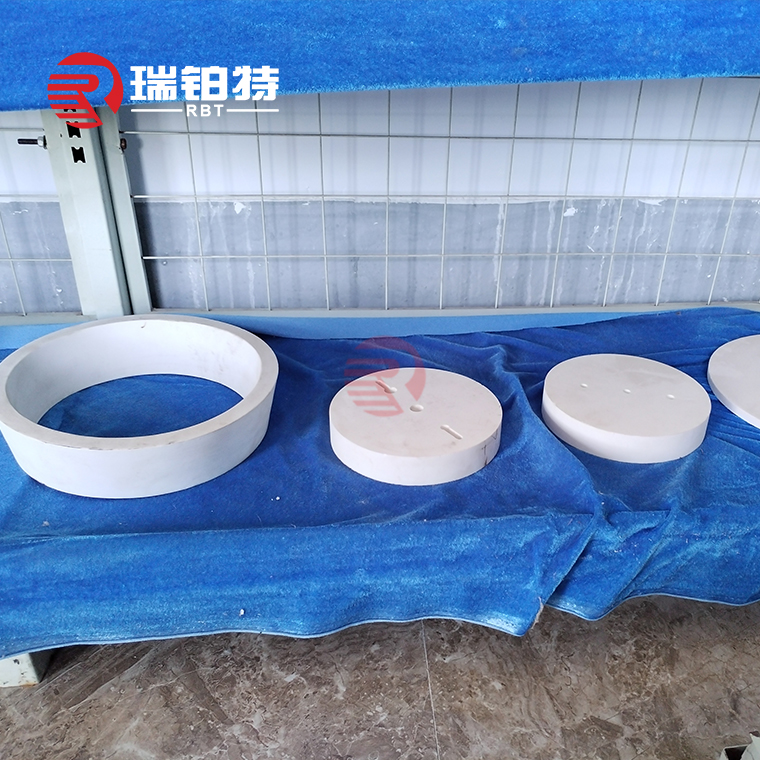

(4) Likarolo tse Khethehileng tsa Ceramic tse sa Apareng

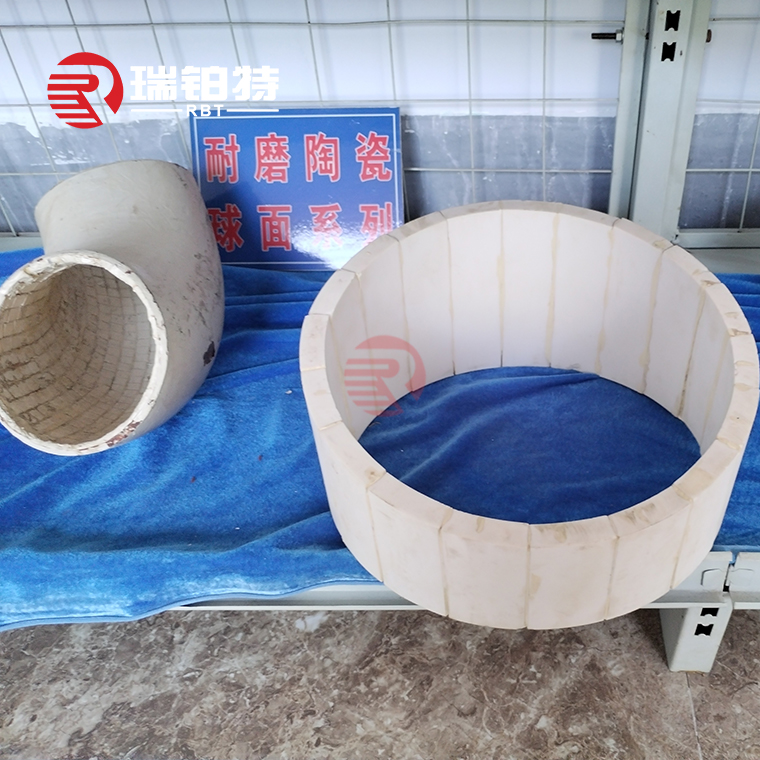

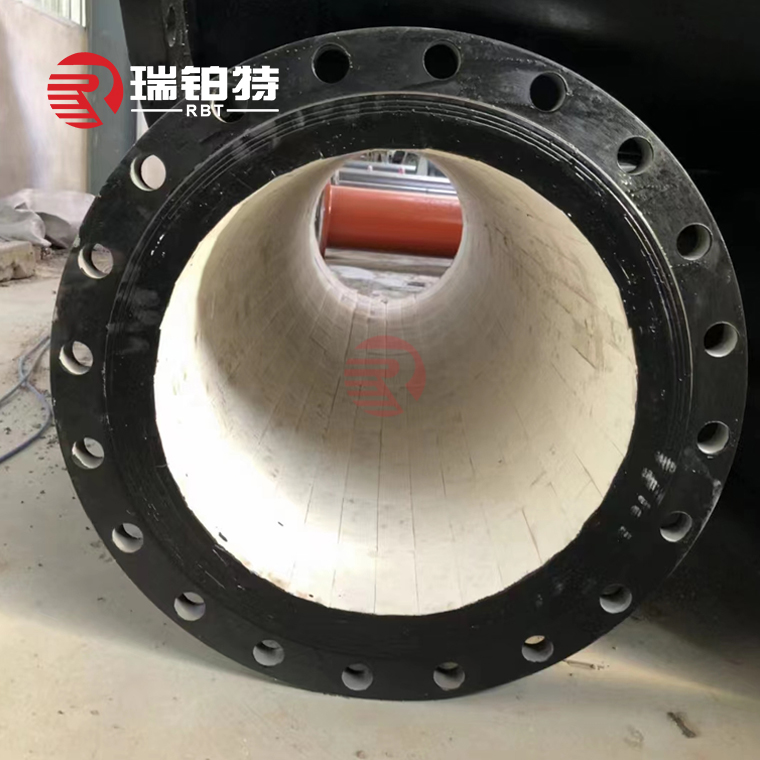

3. Peipi e kopantsoeng ea ceramic e sa sebetseng, Lebitso le feletseng la ceramic lined composite tšepe pipe, ke phala e entsoeng ka mokhoa oa ho hlahisa theknoloji e phahameng - mokhoa oa ho iketsetsa mocheso o phahameng oa clutch synthesis.

Likaroloana:

High wear resistance:Boima ba Mohs ba lesela la corundum ceramic bo ka fihla ho 9.0, e nang le khanyetso e phahameng haholo ea ho apara 'me e loketse ho tsamaisa mecha ea litaba e senyang. "

Corrosion resistance:Lisebelisoa tsa ceramic li na le khanyetso e ntle ho mecha ea litaba e senyang joalo ka li-acids, alkalis le letsoai. "

Ho tsitsisa mocheso o phahameng:Lera la ceramic le na le botsitso bo phahameng ba mocheso le khanyetso ea oxidation, 'me e loketse maemo a mocheso o phahameng. "

Matla a bobebe le a phahameng:Har'a liphaephe tse nang le litlhaloso tse tšoanang le bolelele ba yuniti, pipe e sa sebetseng ea ceramic composite e bobebe ka boima, empa e na le khanyetso e matla ea ho roala le khoholeho ea metsi.

Kopo:

Liphaephe tse sa sebetseng tsa ceramic li sebelisoa haholo ka matla, metallurgy, merafo, mashala, lik'hemik'hale le liindasteri tse ling bakeng sa ho tsamaisa lisebelisoa tsa granular le mecha ea phatlalatso e senyang joalo ka lehlabathe, lejoe, phofo ea mashala, molora, mokelikeli oa aluminium, joalo-joalo.

Mokhoa oa tlhahiso

Pipe ea ceramic e entsoeng ka Centrifugal:E entsoe ka ho sebelisa "theknoloji ea "centrifugal" e ikemetseng ea mocheso oa mocheso o phahameng oa lebelo le phahameng. Mokhoa ona o bonolo 'me litšenyehelo li tlaase. E loketse lipalangoang tsa phofo tsa sebaka se selelele. "

Peipi ea ceramic e manganga:Letlapa la alumina ceramic le manehiloe leboteng le ka hare la phala ka sekhomaretsi se matla se hanyetsanang le mocheso o phahameng. Mokhoa oa ho etsa lihlahisoa o batla o le bonolo 'me litšenyehelo li tlaase. "

Pipe e kopaneng e ikatisang:Ka ho kopanya phofo ea ceramic le phofo ea tšepe, e kenngoa ka har'a lebota le ka hare la phala ho sebelisa motsoako o phahameng oa mocheso le mekhoa ea centrifugal. Pipe ea ceramic e kopantsoeng ka ho feletseng: Powra ea ceramic e tšeloa ka har'a phala ea ceramic ho latela hlobo ebe e kopantsoe le phala ea tšepe.

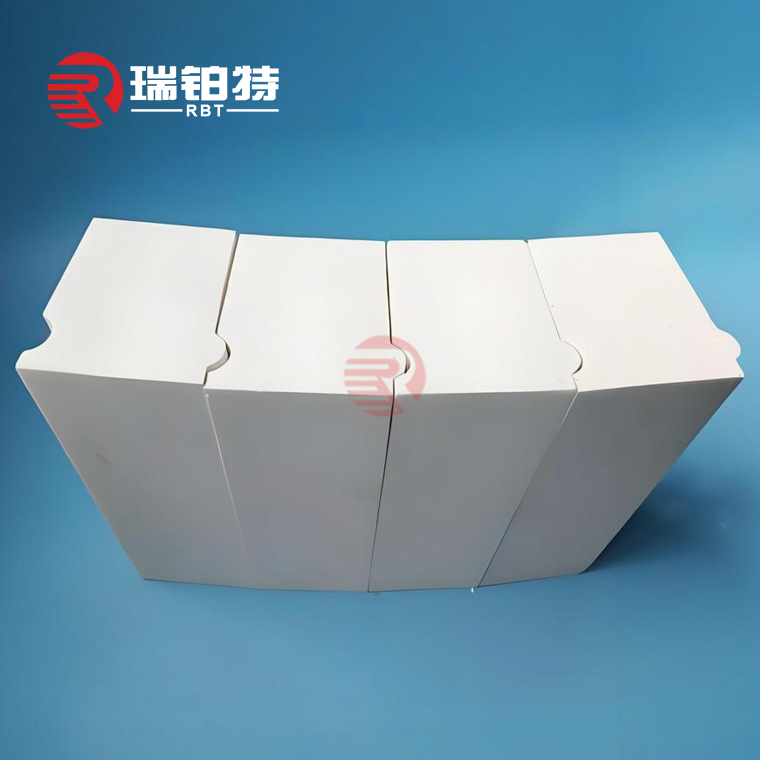

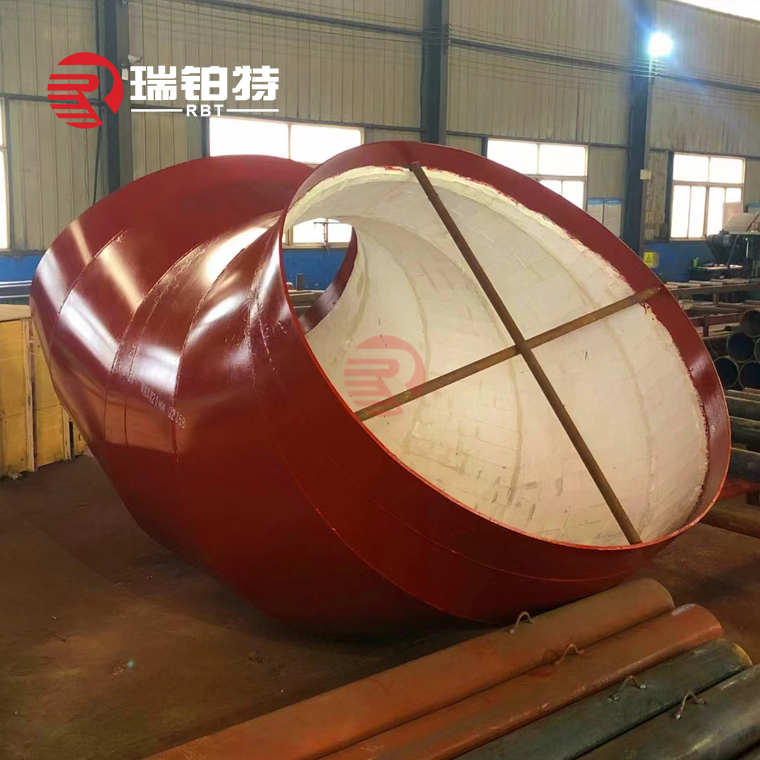

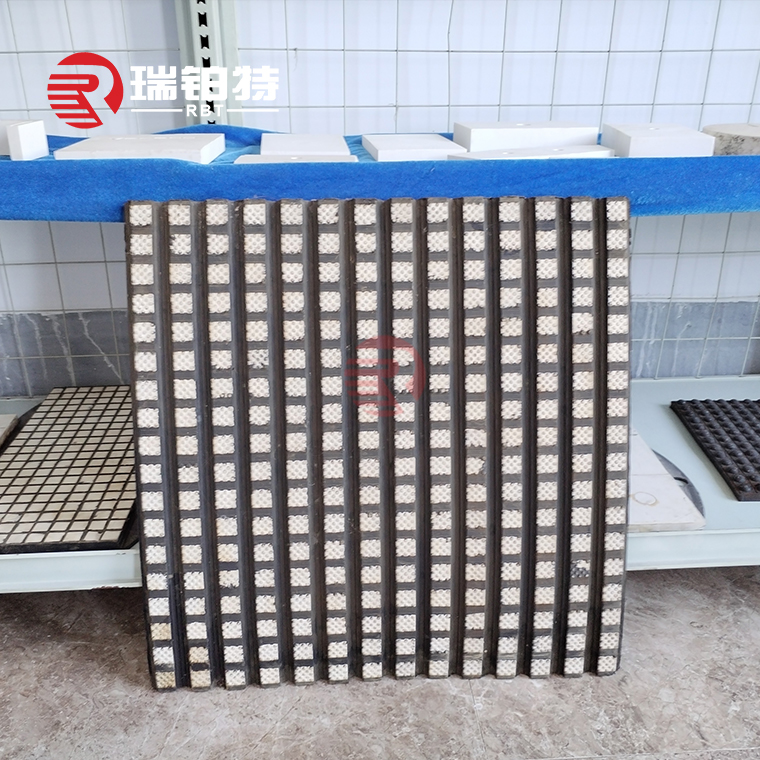

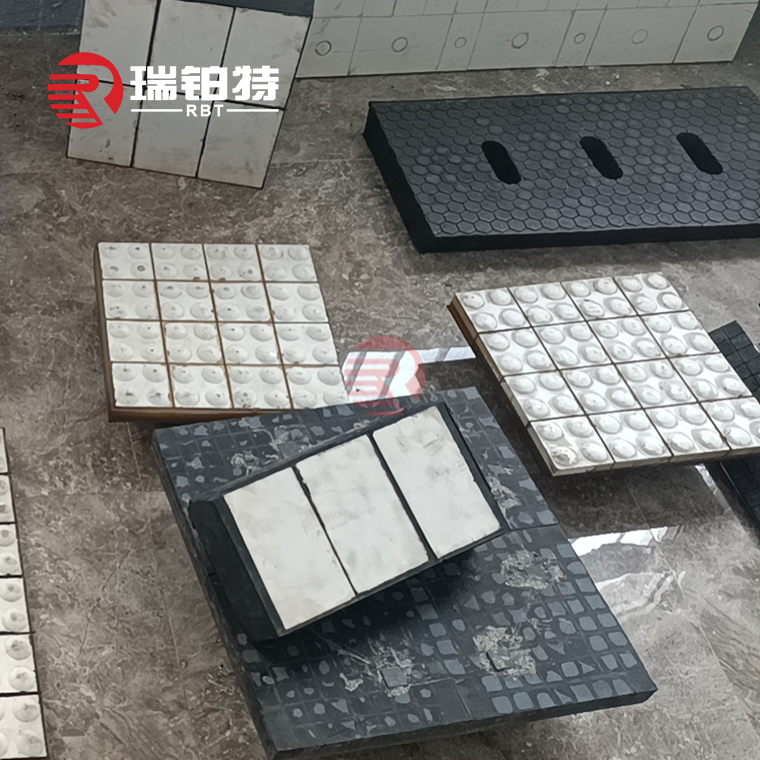

4. Li-ceramic tse peli-in-one le tse tharo ho tse tharolipoleiti tse kopantsoengke lisebelisoa tse kopantsoeng tse kopanyang lisebelisoa tsa ceramic le rabara, tse nang le khanyetso e ntle ea ho apara, ho hanyetsa kutu le ho hanyetsa tšusumetso.

Mokhoa oa tlhahiso

Motsoako oa rabara ea ceramic ea tse peli ho e le 'ngoelipoleiti:Ka thekenoloji ea vulcanization ea rabara, lirafshoa tsa alumina tse thata haholo li kenngoa ka har'a rabara e khethehileng ho etsa motsoako oa rabara ea ceramic. Motsoako ona o na le ts'ebetso e ntle ea cushion 'me e ka khona ho thibela ka katleho tšusumetso ea ore le lisebelisoa tse ling tse theohang holimo. "

Motsoako oa ceramic oa likarolo tse tharo ho o le mong o sa jenglipoleiti:Motheong oa tse peli ho tse le 'ngoe, ho eketsoa lera la tšepe ea tšepe. Ka thekenoloji ea "vulcanization" ea rabara, motsoako oa rabara oa ceramic o ts'oaroa hammoho le poleiti ea tšepe e nang le liboutu tse tekiloeng ho etsa lesela le kopaneng le nang le sebopeho sa tse tharo ho e le 'ngoe. Sebopeho sena se tiisa maqhama a haufi pakeng tsa li-ceramics, rabara le lipoleiti tsa tšepe, ha li ntse li fana ka liphello tse ling tsa ho lokisa.

Litšobotsi tsa ts'ebetso

Wear resistance:Lera la ceramic le na le boima bo phahameng ka ho fetesisa, bo ka hananang le ho roala le ho lelefatsa bophelo ba ts'ebeletso ea lisebelisoa.

"Tšusumetso ea ho hanyetsa:Lera la rabara le na le elasticity e ntle le ho hanyetsa tšusumetso, le ka amohela tšusumetso le ho sisinyeha ho hlahisoang nakong ea ts'ebetso ea lisebelisoa, le ho sireletsa lera la ceramic ho senya. "

Corrosion resistance:Ka bobeli li-ceramics le rabara li na le khanyetso e ntle ea kutu 'me li ka sebetsa ka mokhoa o tsitsitseng nako e telele libakeng tse thata. "

E bobebe:Letlapa la lesela ka har'a sebopeho sa tse tharo-ho-e le 'ngoe le bobebe ho feta 60% ho feta poleiti ea tšepe e manganga, 'me ho bonolo haholo ho e kenya le ho e khutlisa.

Kopo:

Morafo:E sebelisoa bakeng sa lisebelisoa tse sa sebetseng joalo ka mekotla ea bolo, limilone tsa mashala, lifti tsa libakete,scraper conveyors, joalo-joalo ho ntlafatsa ts'ebetso ea ts'ebetso le botsitso ba lisebelisoa. "

Metallurgy:Lisebelisoa tse fapaneng tsa indasteri ea metallurgic, lipoleiti tse entsoeng ka ceramic tse sa sebetseng li ka hanela ka katleho ho roala ha mocheso o phahameng, khatello e phahameng le lisebelisoa tse senyang. "

Motlakase:Tsamaisong ea lipalangoang tsa mashala, lisebelisoa tsa ho tlosa lerōle le likarolo tse ling tsa indasteri ea matla, li fokotsa ho roala ha lisebelisoa le ho fokotsa litšenyehelo tsa tlhokomelo. "

Indasteri ea lik'hemik'hale:Li-reactors, litanka tsa polokelo le lisebelisoa tse ling tsa indasteri ea lik'hemik'hale, li hanela ho senyeha ha mecha ea litaba ea lik'hemik'hale tse sa tšoaneng le ho lelefatsa bophelo ba tšebeletso ea lisebelisoa.

Index ea Lihlahisoa

| Ntho | Al2O3 >92% | 95% | 99% | 99.5% | 99.7% |

| Mmala | Bosoeu | Bosoeu | Bosoeu | 'Mala oa Cream | 'Mala oa Cream |

| Theorytical Density(g/cm3) | 3.45 | 3.50 | 3.75 | 3.90 | 3.92 |

| Bending Strength(Mpa) | 340 | 300 | 330 | 390 | 390 |

| Compressive Strength(Mpa) | 3600 | 3400 | 2800 | 3900 | 3900 |

| Elastic Modulus(Gpa) | 350 | 350 | 370 | 390 | 390 |

| Ho hanyetsana le kameho(Mpam1/2) | 4.2 | 4 | 4.4 | 5.2 | 5.5 |

| Weibull Coefficient(m) | 11 | 10 | 10 | 12 | 12 |

| Vickers Hardness(HV 0.5) | 1700 | 1800 | 1800 | 2000 | 2000 |

| Mocheso oa Katoloso ea Mocheso | 5.0-8.3 | 5.0-8.3 | 5.1-8.3 | 5.5-8.4 | 5.5-8.5 |

| Thermal Conductivity(W/mk) | 18 | 24 | 25 | 28 | 30 |

| Thermal Shock Stability | 220 | 250 | 250 | 280 | 280 |

| Mocheso o phahameng oa ho sebetsa℃ | 1500 | 1600 | 1600 | 1700 | 1700 |

| 20 ℃ Ho hanyetsa Molumo | 10^14 | 10^14 | 10^14 | 10^15 | 10^15 |

| Matla a Dielectric(kv/mm) | 20 | 20 | 20 | 30 | 30 |

| Dielectric Constant | 10 | 10 | 10 | 10 | 10 |

Fektheri Show

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e sebakeng sa Zibo City, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea lintho tse refractory. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea sebōpi, thekenoloji, le thepa ea ho rekisa kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a matla a tekheniki, boleng bo botle ba sehlahisoa le botumo bo botle. Feme ea rona e na le lihekthere tse fetang 200 mme tlhahiso ea selemo le selemo ea thepa e bōpehileng joaloka lithane tse ka bang 30000 'me thepa ea refractory e sa bopehang ke lithane tse 12000.

Lihlahisoa tsa rona tsa mantlha tsa thepa ea refractory li kenyelletsa:lisebelisoa tsa alkaline refractory; lisebelisoa tsa aluminium silicon refractory; thepa e sa bōpehang refractory; lisebelisoa tse thibelang mocheso oa mocheso; thepa e khethehileng refractory; lisebelisoa tse sebetsang tsa refractory bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Khafetsa

U hloka thuso? Etsa bonnete ba hore u etela liforomo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, feme ea rona e khethehile ho hlahisa thepa ea refractory ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ka mor'a ho rekisa.

Bakeng sa ts'ebetso e 'ngoe le e' ngoe ea tlhahiso, RBT e na le tsamaiso e feletseng ea QC bakeng sa metsoako ea lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa,' me setifikeiti sa boleng se tla romelloa ka thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho itšetlehile ka bongata, nako ea rona ea ho fana e fapane. Empa re tšepisa ho romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ha e le hantle, re fana ka mehlala ea mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e molemohali ho latela boemo ba hau.

Re 'nile ra etsa thepa ea refractory ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le phihlelo e ruileng, re ka thusa bareki ho rala li-kilns tse fapaneng le ho fana ka ts'ebeletso e le 'ngoe.