Khabide e Ntšo ea Silicon

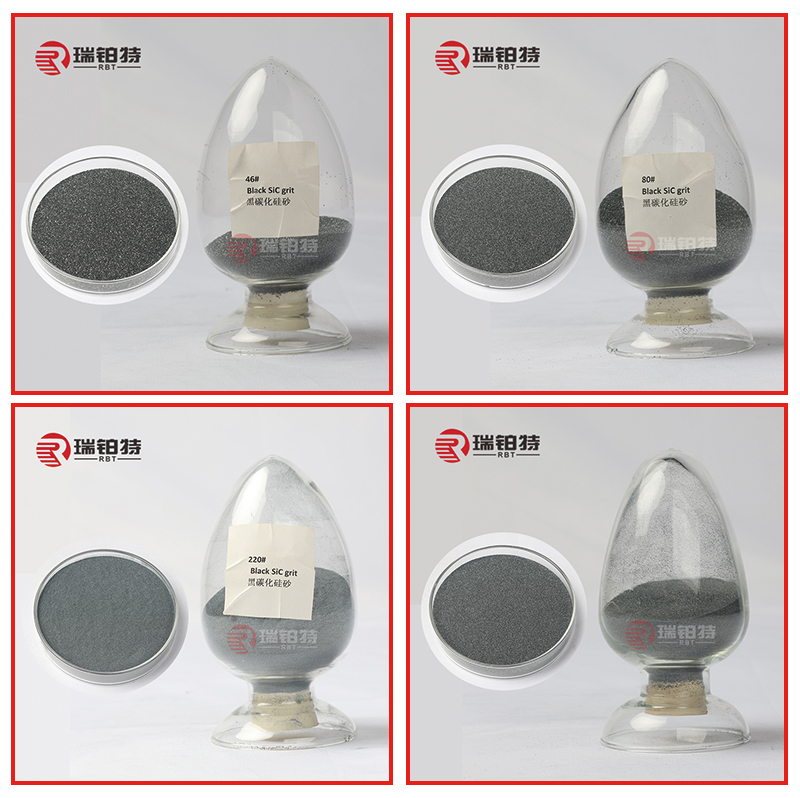

Tlhahisoleseding ea Sehlahisoa

Khabide e Ntšo ea Silicon (SiC)ke diminerale e thata haholo (Mohs 9.1/2550 Knoop) e entsoeng ke motho e nang le conductivity e phahameng ea mocheso le matla a phahameng mochesong o phahameng (ka 1000°C, SiC e matla ho feta Al203 ka makhetlo a 7.5). SiC e na le modulus ea elasticity ea 410 GPa, e se nang phokotso ea matla ho fihlela ho 1600°C, 'me ha e qhibilihe ka khatello e tloaelehileng empa ho e-na le hoo e arohana ho 2600°C.

Likopo:

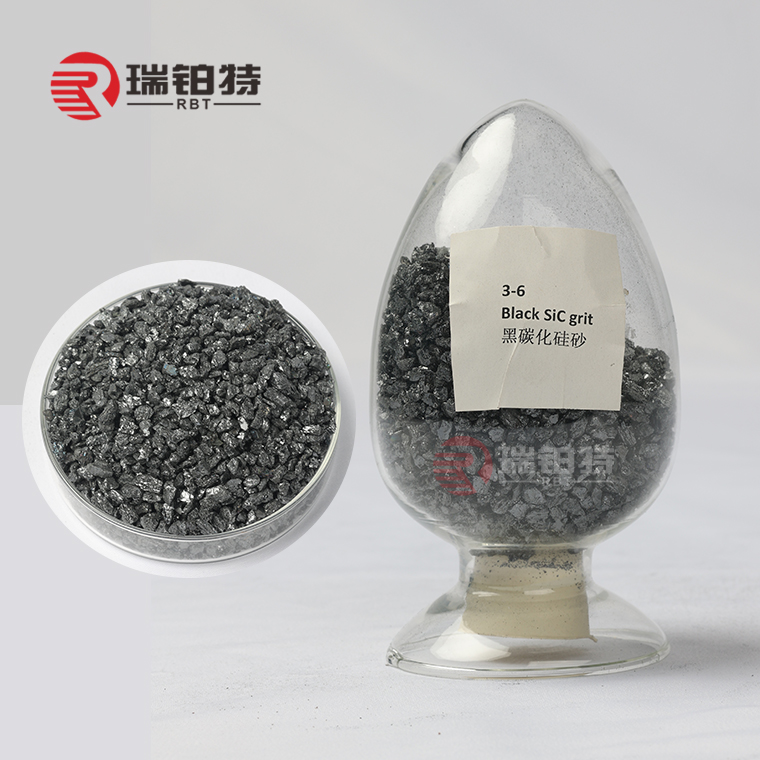

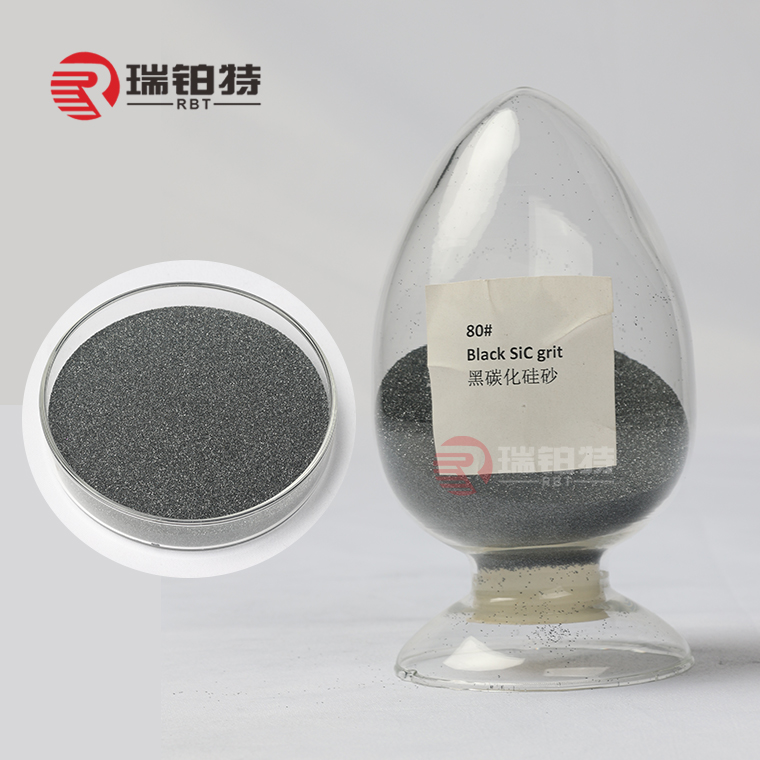

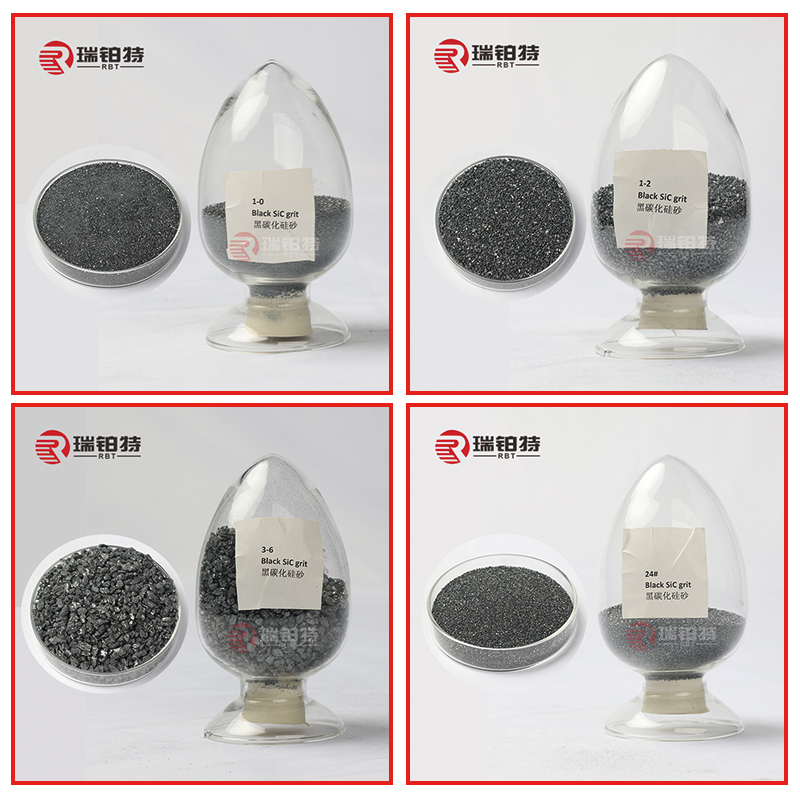

Liboloko tsa carbide tse ntšo tsa siliconhangata li sebelisoa lits'ebetsong tse hlokang ho seha, ho sebetsoa kapa ho sila, joalo ka ho lokisa mabili a ho sila, ho seha li-disc, jj.

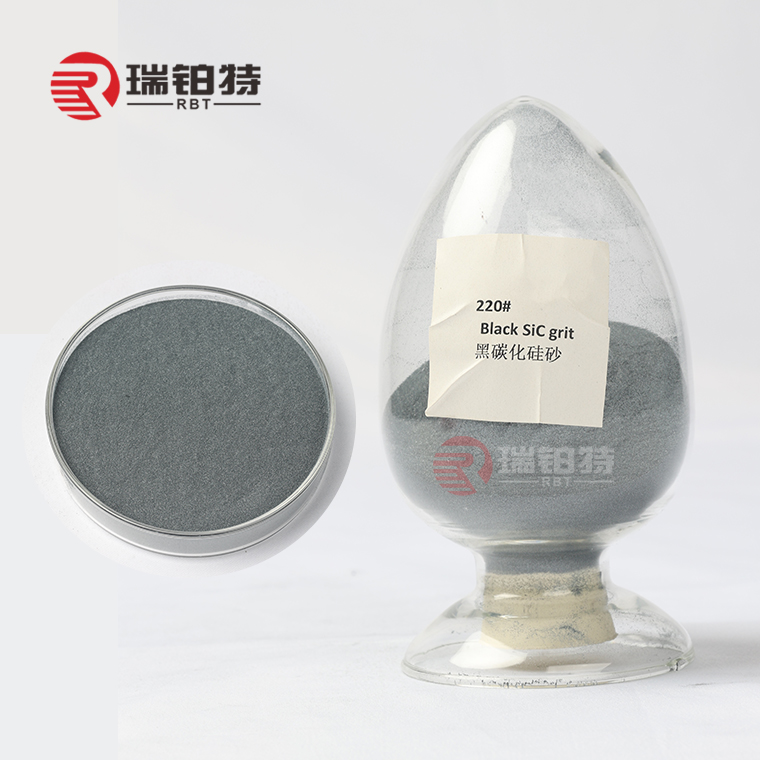

Boholo balehlohlojane le letšo la silicon carbideka kakaretso e tloha ho dimilimithara tse mmalwa ho isa ho tse mashome a di-micron. E sebediswa hangata ho tjheseng lehlabathe, ho bentsha, ho phekola bokahodimo le ditshebediso tse ding ho fana ka bokahodimo bo tshwanang bo kgopameng le bo hlwekileng.

Boholo ba dikarolwana tsaphofo ea khabide e ntšo ea siliconHangata e boemong ba nanometer ho isa ho micron. Lihlahisoa tsa phofo li sebelisoa hangata ho matlafatseng thepa, ho koahela, ho tlatsa le lits'ebetsong tse ling.

Litšoantšo tse qaqileng

Chate ea Papiso ea Boholo ba Grit

| Nomoro ea Grit. | Chaena GB2477-83 | Japane JISR 6001-87 | USA ANSI(76) | 欧洲磨料协FEPA(84) | 国际ISO(86) |

| 4 | 5600-4750 |

| 5600-4750 | 5600-4750 | 5600-4750 |

| 5 | 4750-4000 |

| 4750-4000 | 4750-4000 | 4750-4000 |

| 6 | 4000-3350 |

| 4000-3350 | 4000-3350 | 4000-3350 |

| 7 | 3350-2800 |

| 3350-2800 | 3350-2800 | 3350-2800 |

| 8 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 |

| 10 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 |

| 12 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 |

| 14 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 |

| 16 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 |

| 20 | 1180-1000 | 1180-1100 | 1180-1000 | 1180-1000 | 1180-1000 |

| 22 | 1000-850 | - | - | 1000-850 | 1000-850 |

| 24 | 850-710 | 850-710 | 850-710 | 850-710 | 850-710 |

| 30 | 710-600 | 710-600 | 710-600 | 710-600 | 710-600 |

| 36 | 600-500 | 600-500 | 600-500 | 600-500 | 600-500 |

| 40 | 500-425 | - | - | 500-425 | 500-425 |

| 46 | 425-355 | 425-355 | 425-355 | 425-355 | 425-355 |

| 54 | 355-300 | 355-300 | 355-297 | 355-300 | 355-300 |

| 60 | 300-250 | 300-250 | 297-250 | 300-250 | 300-250 |

| 70 | 250-212 | 250-212 | 250-212 | 250-212 | 250-212 |

| 80 | 212-180 | 212-180 | 212-180 | 212-180 | 212-180 |

| 90 | 180-150 | 180-150 | 180-150 | 180-150 | 180-150 |

| 100 | 150-125 | 150-125 | 150-125 | 150-125 | 150-125 |

| 120 | 125-106 | 125-106 | 125-106 | 125-106 | 125-106 |

| 150 | 106-75 | 106-75 | 106-75 | 106-75 | 106-75 |

| 180 | 90-63 | 90-63 | 90-63 | 90-63 | 90-63 |

| 220 | 75-53 | 75-53 | 75-53 | 75-53 | 75-53 |

| 240 | 75-53 | - | 75-53 | - |

Lethathamo la Sehlahisoa

| Boholo ba Lehlohlojane | Sebopeho sa Lik'hemik'hale% (Ka Boima) | ||

| SIC | F·C | Fe2O3 | |

| 12#-90# | ≥98.50 | ≤0.20 | ≤0.60 |

| 100#-180# | ≥98.00 | ≤0.30 | ≤0.80 |

| 220#-240# | ≥97.00 | ≤0.30 | ≤1.20 |

| W63-W20 | ≥96.00 | ≤0.40 | ≤1.50 |

| W14-W5 | ≥93.00 | ≤0.40 | ≤1.70 |

Kopo

Lisebelisoa tsa ho Sila le tsa ho Abrasive:Ka lebaka la ho ba thata haholo le ho tiea ho itseng, lehlabathe la carbide e ntšo ea silicon le sebelisoa haholo ho sileng le ho benyeng khalase ea optical, carbide e samentetsoeng, motsoako oa titanium, tšepe e beang, le ho leotsa lisebelisoa tsa tšepe tse lebelo le phahameng. E boetse e loketse ho seha le ho sila thepa e nang le matla a tlase a ho tensile, joalo ka ho seha silicon e le 'ngoe ea kristale le lithupa tsa silicon tse nang le polycrystalline, ho sila li-wafer tsa silicon e le 'ngoe ea kristale, jj.

Lisebelisoa tse halefisang:Indastering ea tšepe, lehlabathe le letšo la carbide ea silicon le atisa ho sebelisoa e le lesela, tlase le sekhechana sa lionto tse nang le mocheso o phahameng ho netefatsa ts'ebetso e tloaelehileng ea lisebelisoa tsa tšepe. E boetse e entsoe ka thepa e hanyetsang, joalo ka likarolo tsa onto tse nang le mocheso o phahameng le litšehetso, tse hanelang ho thothomela ha mocheso, tse nyane ka boholo, tse bobebe ka boima le tse matla haholo, 'me li na le litlamorao tse ntle tsa ho boloka matla.

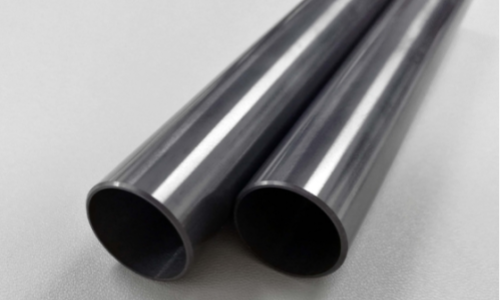

Tšebeliso ea lik'hemik'hale:Indastering ea lik'hemik'hale, lehlabathe la carbide e ntšo ea silicon le sebelisoa ho etsa lisebelisoa tsa lik'hemik'hale tse sa senyeheng, liphaephe le li-valve ho netefatsa ts'ebetso e sireletsehileng ea lisebelisoa tlas'a mecha ea ho senya le maemo a mocheso o phahameng. Ho phaella moo, e ka boela ea sebelisoa e le sesebelisoa sa ho hloekisa tšepe e qhibilihisang, ke hore, sesebelisoa sa ho tlosa oxidizer bakeng sa ho etsa tšepe le sesebelisoa sa ho ntlafatsa sebopeho sa tšepe e entsoeng ka tšepe.

Indasteri ea lisebelisoa tsa elektroniki:Indastering ea lisebelisoa tsa elektroniki, lehlabathe le letšo la silicon carbide le sebelisoa ho etsa lisebelisoa tsa semiconductor le likarolo tsa elektroniki, joalo ka lisebelisoa tsa elektroniki tse matla haholo, li-substrate tsa potoloho tse kopaneng, jj., ho netefatsa ts'ebetso e phahameng le botsitso ba lisebelisoa tsa elektroniki.

Tšebeliso e 'ngoe:Lehlabathe le letšo la silicon carbide le boetse le sebelisoa ho etsa li-ceramic tse sebetsang, likarolo tsa ho futhumatsa tsa motlakase, thepa ea semiconductor ea mocheso o phahameng, liboto tsa infrared tse hole, thepa ea valve ea ho thibela lehalima, jj. E boetse e sebelisoa ho etsa liaparo tsa pane tse sa khomareleng, liaparo tse sa tsofaleng, liaparo tse thibelang ho bola, jj.

Sephutheloana le Ntlo ea polokelo

| Sephutheloana | Mokotla oa 25KG | Mokotla oa 1000KG |

| Bongata | Lithane tse 24-25 | Lithane tse 24 |

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e fumaneha Motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa e hanyetsang. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea ontong, theknoloji le thepa e hanyetsang kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a tekheniki a matla, boleng bo botle ba sehlahisoa, le botumo bo botle. Feme ea rona e akaretsa lihekthere tse fetang 200 'me tlhahiso ea selemo le selemo ea thepa e hanyetsang e bōpehileng joaloka e ka ba lithane tse 30000 'me thepa e hanyetsang e sa bōpehang joaloka e hanyetsang ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa e hanyetsang li kenyelletsa:thepa e hanyetsang alkaline; thepa e hanyetsang silicon ea aluminium; thepa e sa bōpehang e hanyetsang; thepa e thibelang mocheso e thibelang mocheso; thepa e khethehileng e thibelang; thepa e sebetsang e thibelang bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Khafetsa

Na u hloka thuso? Etsa bonnete ba hore u etela liforamo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, fektheri ea rona e ikhethile ka ho hlahisa thepa e hanyetsang ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ea kamora thekiso.

Bakeng sa ts'ebetso e 'ngoe le e 'ngoe ea tlhahiso, RBT e na le sistimi e felletseng ea QC bakeng sa sebopeho sa lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa, 'me setifikeiti sa boleng se tla romelloa le thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho latela bongata, nako ea rona ea ho tlisa thepa e fapane. Empa re tšepisa ho e romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ehlile, re fana ka disampole tsa mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e ntle ka ho fetisisa ho latela boemo ba hau.

Re ntse re etsa thepa e hanyetsang mocheso ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le boiphihlelo bo bongata, re ka thusa bareki ho rala li-kiln tse fapaneng le ho fana ka tšebeletso ea ho emisa hang feela.