Selelekela

Liindastering tse nang le mocheso o phahameng—ho tloha ho etseng tšepe ho isa tlhahisong ea khalase—thepa e halefisang ke motheo oa ts'ebetso e sireletsehileng le e sebetsang hantle. Har'a tsena,litene tsa mulliteli hlahella ka botsitso ba tsona bo ikhethang ba mocheso, ho hanyetsa mafome, le matla a mechini. Ho utloisisa lihlopha tsa tsona le ts'ebeliso ho bohlokoa bakeng sa likhoebo tse batlang ho ntlafatsa nako ea lisebelisoa le ho fokotsa litšenyehelo tsa ts'ebetso. Sengoloa sena se hlalosa mefuta ea bohlokoa ea litene tsa mullite le ts'ebeliso ea tsona ea lefats'e la 'nete, ho u thusa ho etsa liqeto tse nang le tsebo bakeng sa litlhoko tsa hau tsa indasteri.

Tlhophiso ea Litene tsa Mullite

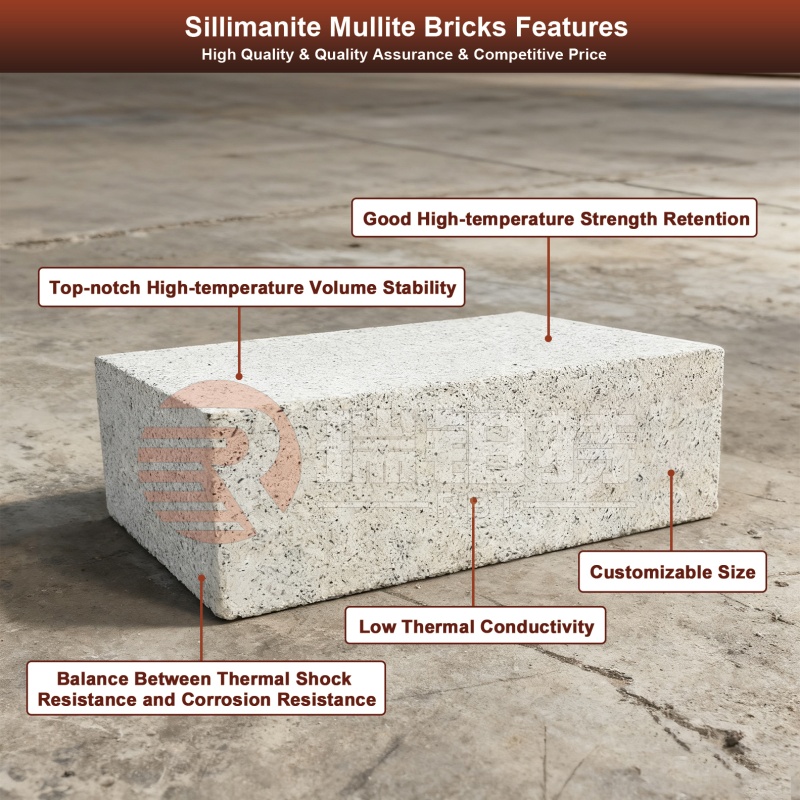

Litene tsa Mullite li arotsoe ka lihlopha ho latela mekhoa ea tlhahiso le likarolo tse ekelitsoeng, e 'ngoe le e 'ngoe e etselitsoe litlhoko tse itseng tsa indasteri.

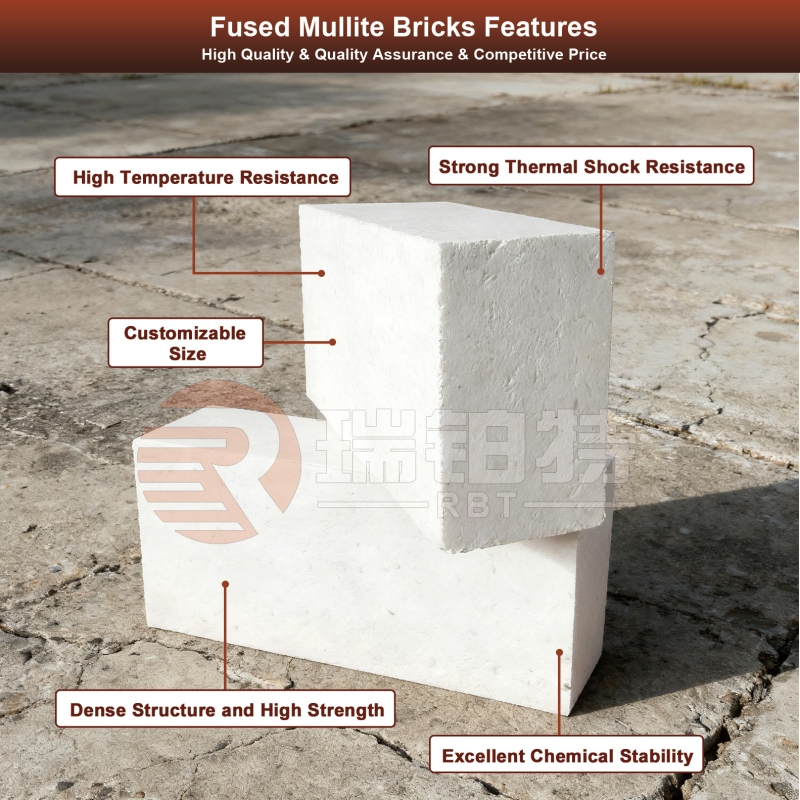

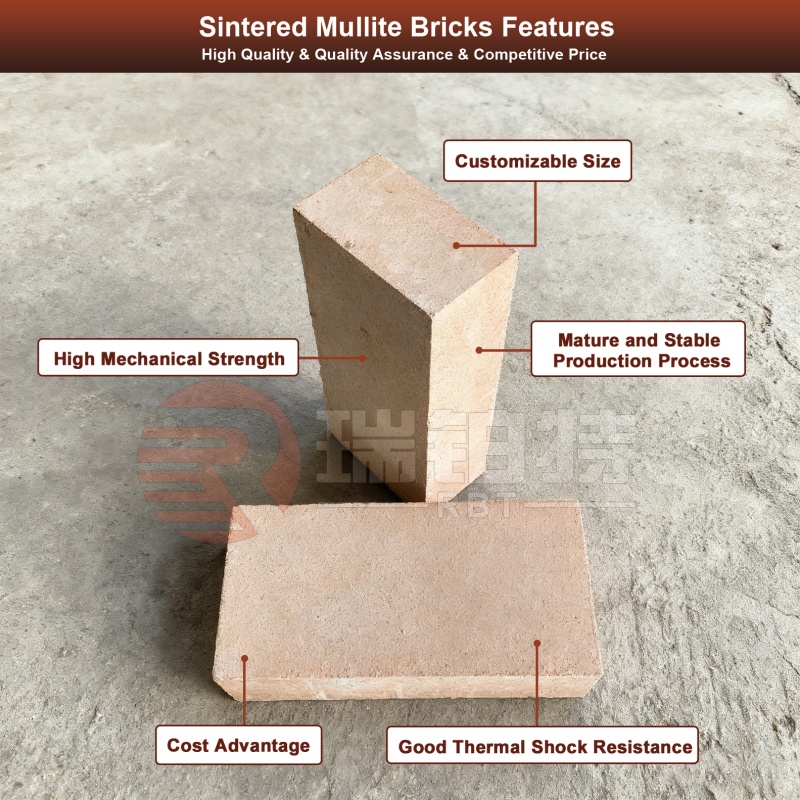

1. Litene tse nang le Sintered Mullite

E entsoe ka ho kopanya alumina le silika e hloekileng haholo, ho bopa motsoako, le ho o silafatsa mochesong o kaholimo ho 1600°C, litene tsa mullite tse sintered li na le sebopeho se teteaneng le masoba a tlase (hangata li ka tlase ho 15%). Litšobotsi tsena li li fa khanyetso e ntle ea ho tsofala le khanyetso ea mocheso—e loketseng libaka tse nang le liphetoho tse ngata tsa mocheso. Tšebeliso e tloaelehileng e kenyelletsa masela a li-kiln tsa ceramic, li-stove tsa blast furnace tse chesang, le likamore tsa ho chesa tsa boiler.

2. Litene tsa Mullite tse entsoeng ka motsoako

Li hlahisoa ka ho qhibilihisa thepa e tala (alumina, silika) ka sebōping sa motlakase sa arc (se fetang 2000°C) le ho lahlela motsoako o qhibilihisitsoeng ka har'a hlobo, litene tsa mullite tse kopantsoeng ka motsoako li na le maemo a litšila a tlase haholo le bohloeki bo phahameng ba kristale. Ho hanyetsa ha tsona ho phahameng khoholehong ea lik'hemik'hale (mohlala, ho tsoa khalaseng e qhibilihisitsoeng kapa slags) ho li etsa khetho e ntle bakeng sa li-regenerator tsa sebōping sa khalase, libate tsa khalase tse phaphametseng le lisebelisoa tse ling tse pepesetsoeng ke mecha e matla e qhibilihisitsoeng.

3. Litene tse bobebe tsa Multite

Li entsoe ka ho eketsa metsoako e etsang masoba (mohlala, lerōle la mapolanka, graphite) nakong ea tlhahiso, litene tse bobebe tsa mullite li na le masoba a 40-60% le bongata bo tlase haholo ho feta mefuta e sintered kapa e kopantsoeng. Molemo oa tsona oa bohlokoa ke conductivity e tlase ea mocheso (0.4-1.2 W/(m·K)), e fokotsang tahlehelo ea mocheso. Li sebelisoa haholo e le likarolo tsa ho thibela mocheso ka har'a li-oven, li-oven le lisebelisoa tsa kalafo ea mocheso, moo boima le ts'ebetso ea matla e leng lintho tsa bohlokoa.

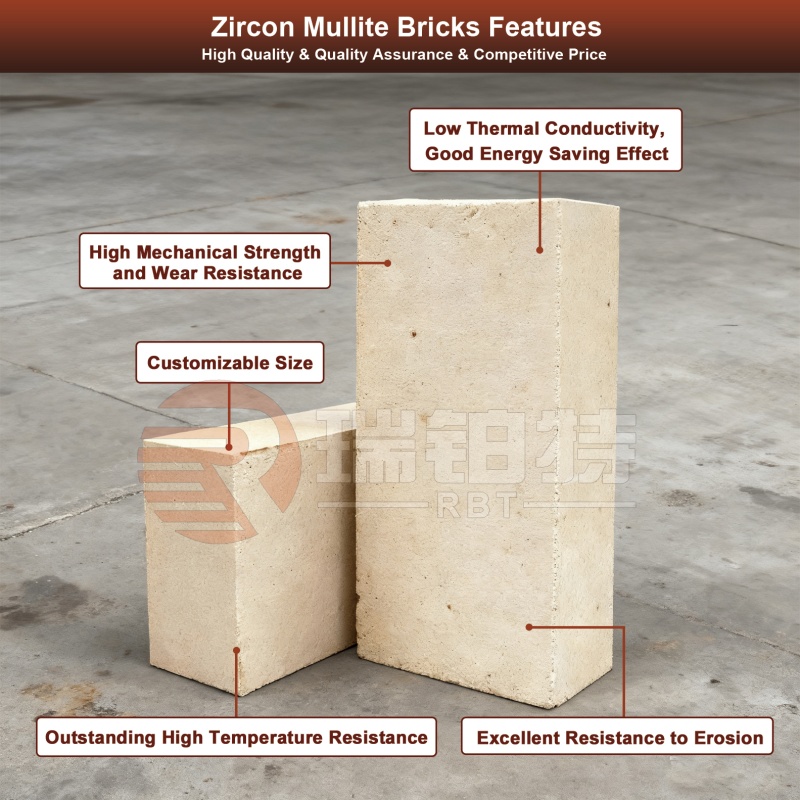

4. Litene tsa Zircon Mullite

Ka ho kenyelletsa zircon (ZrSiO₄) motswakong wa thepa e tala, ditene tsa zircon mullite di fumana tshebetso e ntlafetseng ya mocheso o phahameng—di ka mamella mocheso ho fihlela ho 1750°C mme tsa hanela kgoholeho ya mobu e bakwang ke mafome a asiti. Sena se etsa hore di lokele ditikoloho tse thata tse kang dionto tsa ho qhibilihisa tshepe tse se nang ferrous (mohlala, disele tsa ho fokotsa aluminium) le dibaka tsa ho tjhesa samente rotary oven.

Litšebeliso tsa Litene tsa Mullite

Ho tenyetseha ha litene tse ngata ho etsa hore li be bohlokoa haholo liindastering tse ngata tse nang le mocheso o phahameng.

1. Indasteri ea Tšepe

Tlhahiso ea tšepe e kenyelletsa mocheso o feteletseng (ho fihlela ho 1800°C) le litšila tse senyang. Litene tsa mullite tse sintered li koahela litofo tse chesang tse chesang, moo ho hanyetsa ha tsona mocheso ho thibelang ho petsoha ho futhumala/ho pholisa ka potlako. Mefuta e kopantsoeng e sireletsa lilae le li-tundishes, e fokotsa khoholeho ea litšila le ho eketsa bophelo ba lisebelisoa ka 20-30% ha ho bapisoa le mekhoa ea setso ea ho hanyetsa.

2. Indasteri ea samente

Li-oven tse potolohang tsa samente li sebetsa mochesong oa 1450–1600°C, 'me marotholi a alkaline a baka kotsi e kholo ea khoholeho ea mobu. Litene tsa zircon mullite li potoloha sebaka sa ho chesa sa oven, li hanela litlhaselo tsa alkali le ho boloka botsitso ba sebopeho. Litene tse bobebe tsa mullite le tsona li sebetsa e le mealo ea ho thibela ho chesa, li fokotsa tšebeliso ea matla ka 10–15%.

3. Indasteri ea Khalase

Khalase e qhibilihisitsoeng (1500–1600°C) e senya haholo, e leng se etsang hore litene tsa mullite tse kopantsoeng ka motsoako li be bohlokoa bakeng sa li-regenerator tsa khalase le li-lining tsa litanka. Li thibela tšilafalo ea khalase 'me li eketsa nako ea ho sebetsa ha setofo ho fihlela lilemong tse 5-8, ho tloha lilemong tse 3-5 ka thepa e 'ngoe.

4. Liindasteri tse ling

Ha ho qhibilihisoa tšepe e se nang ferrous (aluminium, koporo), litene tsa zircon mullite li hanela ho khoholeha ha tšepe e qhibilihisitsoeng le slag. Likhemikhaleng tsa petrochemical, litene tsa mullite tse sintered li kopanya lifono tse petsohang ka lebaka la botsitso ba tsona ba mocheso. Li-ceramics, litene tsa mullite tse bobebe li sireletsa li-oven, e leng se fokotsang tšebeliso ea matla.

Qetello

Mefuta e fapaneng ea litene tsa mullite—tse sintered, tse kopantsoeng ka motsoako, tse bobebe, le zircon—li fihlela litlhoko tse ikhethang tsa liindasteri tse nang le mocheso o phahameng. Ho tloha ho ntlafatseng katleho ea setofo sa tšepe ho isa ho holiseng bophelo ba setofo sa khalase, li fana ka melemo e bonahalang: nako e telele ea ho phela ha lisebelisoa, litšenyehelo tse tlase tsa matla, le nako e fokotsehileng ea ho se sebetse. Ha liindasteri li ntse li phehella tlhahiso e phahameng le botsitso, litene tsa mullite li tla lula e le tharollo ea bohlokoa. Khetha mofuta o nepahetseng bakeng sa ts'ebeliso ea hau, 'me u notlolle bokhoni ba tsona bo felletseng.

Nako ea poso: Mphalane-31-2025