Seretse se sa khanyeng

Tlhahisoleseding ea Sehlahisoa

Seretse se hanelang,e tsejoang hape e le seretse sa mollo kapa thepa e kopaneng (phofo), e sebelisoang e le lihlahisoa tse kopanyang tse hanyetsang thepa ea litene, ho latela thepa e ka aroloa ka likarolo tse peli.letsopa, aluminium e ngata, silicon le seretse se sa sebetseng hantle sa magnesium, jj.

E bitsoaseretse se tloaelehileng se hanyetsange entsoe ka phofo ea clinker e sa fetoheng le letsopa la polasetiki e le binder le polasetiki. Matla a eona mochesong oa kamore a tlase, 'me ho thehoa ha bond ea ceramic mochesong o phahameng ho na le matla a phahameng. Ka hydraulicity, ho thatafatsa moea kapa thepa ea thermo-hardening e le binder, e bitsoangseretse se tlamang sa lik'hemik'hale se sa sebetseng, jwalo ka tlase ho sebopeho sa mocheso wa ho tlama wa ceramic pele ho tlhahiso ya karabelo e itseng ya dikhemikhale le ho thatafala.

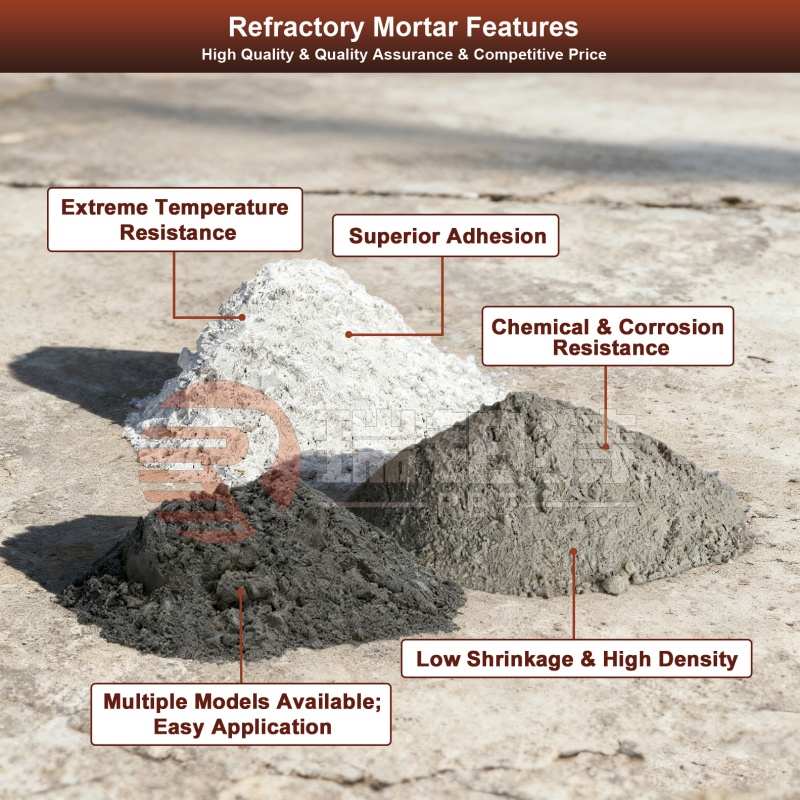

Litšobotsi tsa seretse se halefisang:polasetiki e ntle, kaho e bonolo; matla a tlamo e phahameng, ho hanyetsa mafome ka matla; ho hanyetsa ho hoholo, ho fihla ho 1650℃±50℃; ho hanyetsa ho hlasetsoa ha slag hantle; thepa e ntle ea ho qhala mocheso.

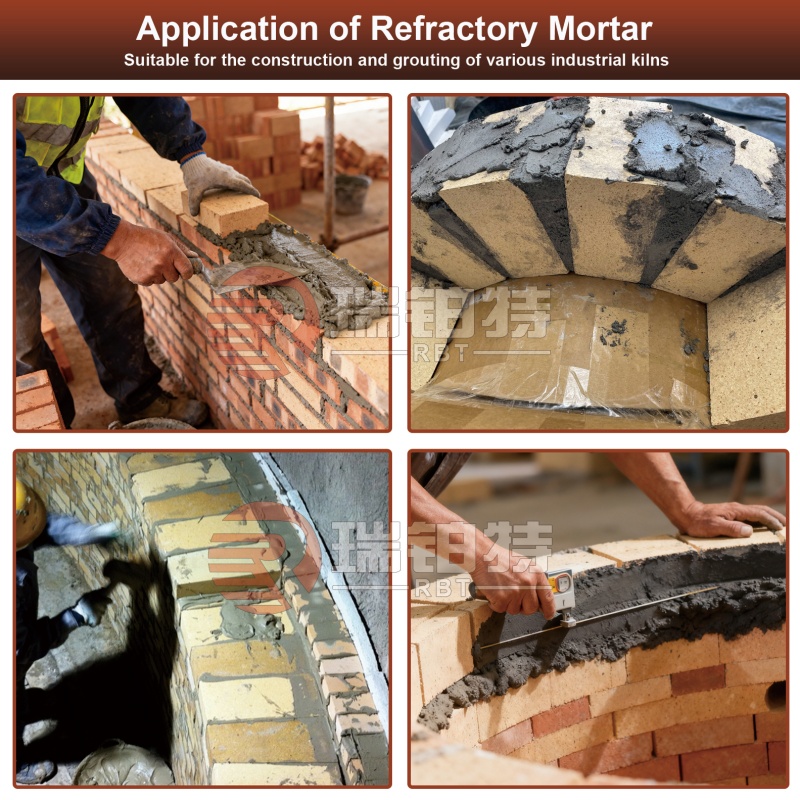

Seretse se hanelang se sebelisoa haholo-holo ka ontong ea coke, ontong ea khalase, ontong ea ho phatloha, setofong se chesang sa ho phatloha, tšepe, indasteri ea thepa ea meralo, mechini, petrochemical, khalase, boiler, motlakase, tšepe le tšepe, samente le ontong e 'ngoe ea indasteri.

Lethathamo la Sehlahisoa

| Index | Letsopa | Alumina e Phahameng | ||||

| RBTMN-42 | RBTMN-45 | RBTMN-55 | RBTMN-65 | RBTMN-75 | ||

| Li-refractorine (℃) | 1700 | 1700 | 1720 | 1720 | 1750 | |

| CCS/MOR(MPa)≥ | 110℃×24h | 1.0 | 1.0 | 2.0 | 2.0 | 2.0 |

| 1400℃×3h | 3.0 | 3.0 | 4.0 | 4.0 | 4.0 | |

| Nako ea ho Kopanya (metsotso) | 1~2 | 1~2 | 1~2 | 1~2 | 1~2 | |

| Al2O3(%) ≥ | 42 | 45 | 55 | 65 | 75 | |

| SiO2(%) ≥ | — | — | — | — | — | |

| MgO(%) ≥ | — | — | — | — | — | |

| Index | Corundum | Silika | E bobebe | ||

| RBTMN-85 | RBTMN-90 | RBTMN-90 | RBTMN-50 | ||

| Li-refractorine (℃) | 1800 | 1820 | 1670 | | |

| CCS/MOR(MPa)≥ | 110℃×24h | 2.0 | 2.0 | 1.0 | 0.5 |

| 1400℃×3h | 3.5 | 3.0 | 3.0 | 1.0 | |

| Nako ea ho Kopanya (metsotso) | 1~3 | 1~3 | 1~2 | 1~2 | |

| Al2O3(%) ≥ | 85 | 90 | — | 50 | |

| SiO2(%) ≥ | — | — | 90 | — | |

| MgO(%) ≥ | — | — | — | — | |

| Index | Magnesia | |||

| RBTMN-92 | RBTMN-95 | RBTMN-95 | ||

| Li-refractorine (℃) | 1790 | 1790 | 1820 | |

| CCS/MOR(MPa)≥ | 110℃×24h | 1.0 | 1.0 | 1.0 |

| 1400℃×3h | 3.0 | 3.0 | 3.0 | |

| Nako ea ho Kopanya (metsotso) | 1~3 | 1~3 | 1~3 | |

| Al2O3(%) ≥ | — | — | — | |

| SiO2(%) ≥ | — | — | — | |

| MgO(%) ≥ | 92 | 95 | 97 | |

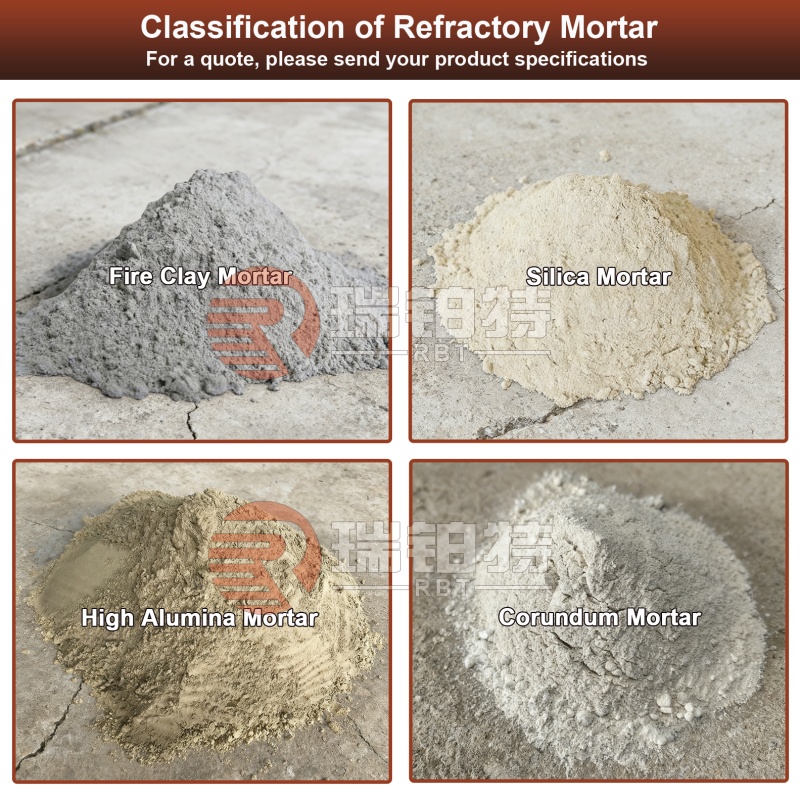

1. Seretse se nang le mouoane se entsoeng ka letsopa

Litšebeliso tsa Bohlokoa:E loketse ho beha litene tse hanelang tse thehiloeng letsopa libakeng tse nang le mocheso o kaholimo ho 1350℃, joalo ka likarolo tse mocheso o tlase tsa li-oven tsa indasteri, li-flue, li-chimney, likarolo tse tlase tsa li-regenerator tsa litofo tse chesang, le li-lining tsa boiler—kaofela li le libakeng tse nang le mafome a tlase, tse mahareng ho isa ho tse tlase.

Likaroloana:Litšenyehelo tse tlase, ho sebetsa hantle, ho hanyetsa mocheso le pholiso ka potlako ka mokhoa o itekanetseng; ha e lokele libaka tse qhibilihisitsoeng tse nang le mocheso o phahameng/libaka tse senyang haholo.

2. Seretse se nang le alumina e ngata se hananang le ho tjhesa

Likopo tsa mantlha:NM-50/NM-60: E loketse litene tse nang le alumina e ngata (Al₂O₃ 55%~65%), tse sebelisoang karolong ea mocheso o mahareng oa li-kiln (1350~1500℃), joalo ka li-kiln tsa ceramic, li-oven tsa metallurgical tse futhumatsang, le libaka tsa phetoho ea samente ea rotary kiln; NM-70/NM-75: E loketse litene tse nang le alumina e ngata (Al₂O₃ ≥70%) kapa litene tsa corundum, tse sebelisoang karolong ea mocheso o phahameng (1500~1700℃), joalo ka li-lining tsa blast oven, li-tapholes tsa steelmaking converter, li-regenerator tsa khalase oven, le li-lining tsa calcium carbide oven.

Likaroloana:Ho hanyetsa ho hoholo, ho hanyetsa ho qhibilihisa ha mashala ha ho bapisoa le mashala a entsoeng ka letsopa; ha Al₂O₃ e le ngata, ho hanyetsa mocheso o phahameng le khoholeho ea mobu ho ba matla le ho feta.

3. Seretse se Hanyetsang Silika

Tšebeliso ea Bohlokoa:E lumellana le litene tsa silika, tse etselitsoeng ka ho khetheha maemo a asiti joalo ka lionto tsa coke, mabota a onto ea khalase/mabota a sefuba, le lionto tsa tšepe tse etsang asiti. Mocheso oa ts'ebetso oa nako e telele: 1600~1700℃.

Likaroloana:E hanela khoholeho ea slag ea asiti; e lumellana hantle le katoloso ea mocheso le litene tsa silika, empa e hanyetsa alkali hampe; e thibetsoe ka thata ho sebelisoa liontong tsa alkaline.

4. Massica / Magnesium-chrome Refractory Mortar

Tšebeliso ea Bohlokoa: Massica:E lumellana le litene tsa magnesia; e sebelisoa maemong a slag e matla ea alkaline joalo ka li-converter tsa alkaline steelmaking, lipelo/mabota a onto ea motlakase ea arc, le lionto tsa tšepe tse sa qhibiliheng.

Magnesium-chrome:E lumellana le litene tsa magnesia-chrome; e sebelisoa maemong a khoholeho ea alkaline a mocheso o phahameng joalo ka libaka tsa ho besa tsa samente rotary oven, li-incinerator tsa litšila, le lionto tsa ho qhibilihisa tšepe tse se nang ferrous.

Likaroloana:Ho hanyetsa ka matla haholo alkaline slag, empa ho hanyetsa ka matla ho futhumatsa le ho phodisa ka potlako; ho latela tikoloho hoa hlokahala bakeng sa magnesia-chrome refractory slurry (libaka tse ling li thibela ho ntšoa ha chromium e nang le hexavalent).

5. Seretse se hanyetsang sa silicon carbide

Likopo tsa mantlha:E loketse litene tsa silicon carbide/litene tsa silicon carbide tse kopantsoeng le nitride, tse sebelisoang lits'ebetsong tsa mocheso o phahameng, tse sa tsofaleng, le tse fokotsang moea tse kang li-tapping tsa blast oven, li-lining tsa tšepe tsa ladle, liphaephe tsa coking oven riser, le likamore tsa bobeli tsa ho chesa tsa li-incinerator tsa litšila.

Likaroloana:Ho tsamaisa mocheso ka lebelo le phahameng, ho hanyetsa ho tsofala ho phahameng, ho hanyetsa ho oxidation mochesong o phahameng, le bophelo ba ts'ebeletso bo phahametseng haholo letsopa la setso/li-alumina tse nang le alumina e ngata.

6. Seretse se sa keneng sa samente e tlase/se se nang samente

Likopo tsa mantlha:E loketse ho lokisa/ho betla di-castable tse se nang samente e tlase/samente kapa ditene tse nang le sebopeho sa refractory, e sebediswang bakeng sa ho kopanya di-oven tse kgolo tsa diindasteri le ho betla ka nepo di-oven tse nang le mocheso o phahameng (jwalo ka di-oven tsa khalase le dioven tsa motlakase tsa metallurgical), ka mocheso o sebetsang wa 1400~1800℃.

Likaroloana:Metsi a fokolang, ho ba le bongata bo boholo le matla ka mor'a ho sila, ha ho na mathata a katoloso ea bophahamo a bakoang ke ho nosetsoa ha samente, le ho hanyetsa khoholeho e ntle haholo.

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e fumaneha Motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa e hanyetsang. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea ontong, theknoloji le thepa e hanyetsang kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a tekheniki a matla, boleng bo botle ba sehlahisoa, le botumo bo botle. Feme ea rona e akaretsa lihekthere tse fetang 200 'me tlhahiso ea selemo le selemo ea thepa e hanyetsang e bōpehileng joaloka e ka ba lithane tse 30000 'me thepa e hanyetsang e sa bōpehang joaloka e hanyetsang ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa e hanyetsang li kenyelletsa:thepa e hanyetsang alkaline; thepa e hanyetsang silicon ea aluminium; thepa e sa bōpehang e hanyetsang; thepa e thibelang mocheso e thibelang mocheso; thepa e khethehileng e thibelang; thepa e sebetsang e thibelang bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Khafetsa

Na u hloka thuso? Etsa bonnete ba hore u etela liforamo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, fektheri ea rona e ikhethile ka ho hlahisa thepa e hanyetsang ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ea kamora thekiso.

Bakeng sa ts'ebetso e 'ngoe le e 'ngoe ea tlhahiso, RBT e na le sistimi e felletseng ea QC bakeng sa sebopeho sa lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa, 'me setifikeiti sa boleng se tla romelloa le thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho latela bongata, nako ea rona ea ho tlisa thepa e fapane. Empa re tšepisa ho e romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ehlile, re fana ka disampole tsa mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e ntle ka ho fetisisa ho latela boemo ba hau.

Re ntse re etsa thepa e hanyetsang mocheso ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le boiphihlelo bo bongata, re ka thusa bareki ho rala li-kiln tse fapaneng le ho fana ka tšebeletso ea ho emisa hang feela.