Sesebelisoa sa ho omisa sa Silicon Carbide

Lihlopha tsa Lihlahisoa

1. Lihlahisoa tsa carbide tsa silicon tse sintered ka karabelo (Lihlahisoa tsa RBSiC)

Carbide ea silicon e kopantsoeng le karabelo (RBSiC) ke thepa e tsoetseng pele ea ceramic ea boenjiniere e hlahisang mohato oa ho kopanya silicon carbide ka ho arabela carbon e lokolohileng le silicon e metsi tlas'a maemo a mocheso o phahameng. Likarolo tsa eona tsa mantlha li kenyelletsa matrix ea silicon carbide (SiC) le silicon e lokolohileng (Si). Ea pele e fana ka thepa e ntle ea mechini, ho hanyetsa ho tsofala le botsitso ba mocheso o phahameng,

ha ya morao e tlatsa masoba a pakeng tsa dikarolwana tsa silicon carbide ho ntlafatsa bongata le botsitso ba sebopeho sa thepa.

(1) Litšobotsi:

Boiketlo ba mocheso o phahameng:Mocheso o phahameng ka ho fetisisa oa ts'ebetso ke 1350℃.

Ho hanyetsa ho roala le ho hanyetsa ho bola:E loketse maemo a thata a mosebetsi a mocheso o phahameng, asiti, alkali le tšepe e qhibilihisitsoeng.

Ho khanna ha mocheso o phahameng le coefficient e tlase ea katoloso ea mocheso:Ho tsamaisa mocheso ho fihla ho 120-200 W/(m·K), mme coefficient ya katoloso ya mocheso ke 4.5×10⁻⁶ K⁻¹ feela, e leng se thibelang ho petsoha ha mocheso le mokhathala wa mocheso ka katleho.

Anti-oxidation:Lera le teteaneng la tšireletso ea silika le hlahisoa holim'a metsi mochesong o phahameng ho lelefatsa bophelo ba tšebeletso.

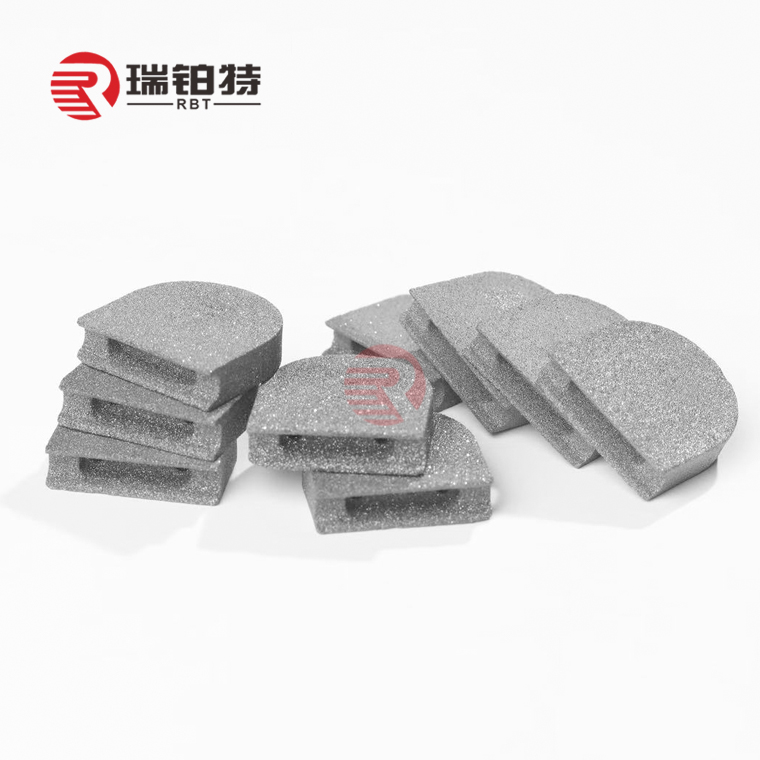

(2) Lihlahisoa tse ka Sehloohong:

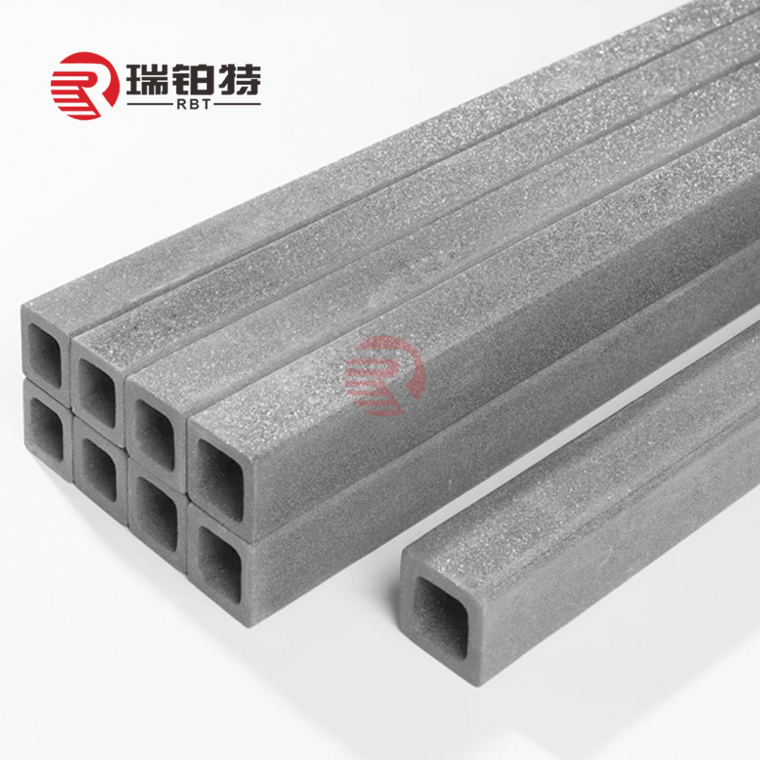

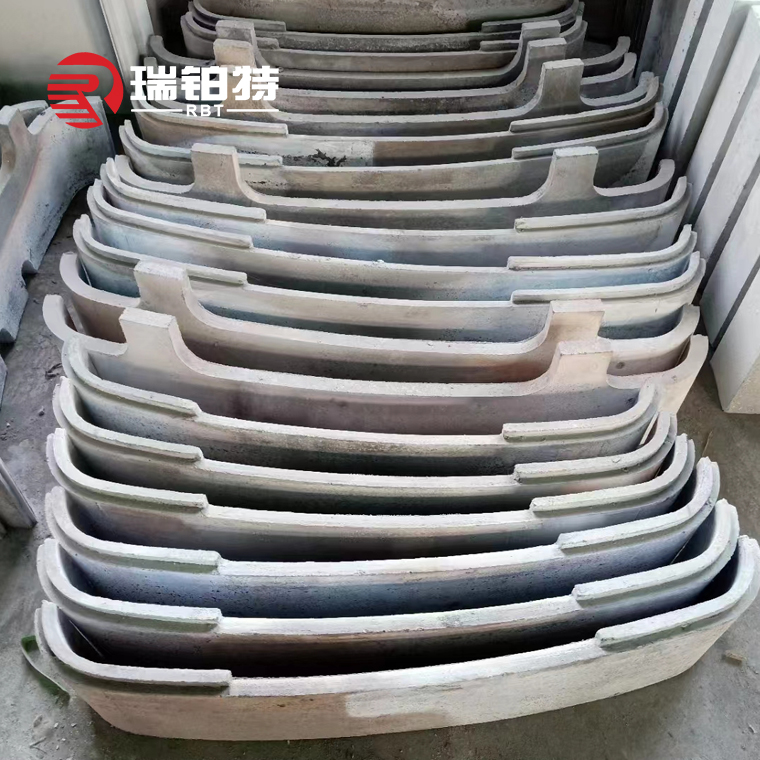

Lehlakore la silicon carbide:e sebediswa bakeng sa sebopeho se jarang mojaro sa di-kiln tsa kotopo, di-kiln tsa shuttle le di-kiln tse ding tsa indasteri, tse nang le kganyetso e ntle ya mocheso o phahameng.

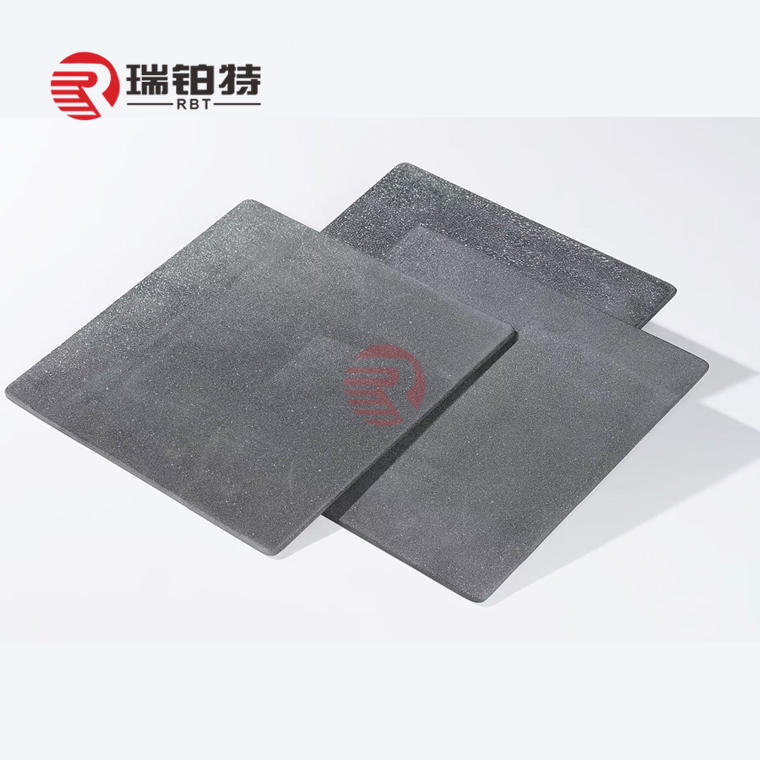

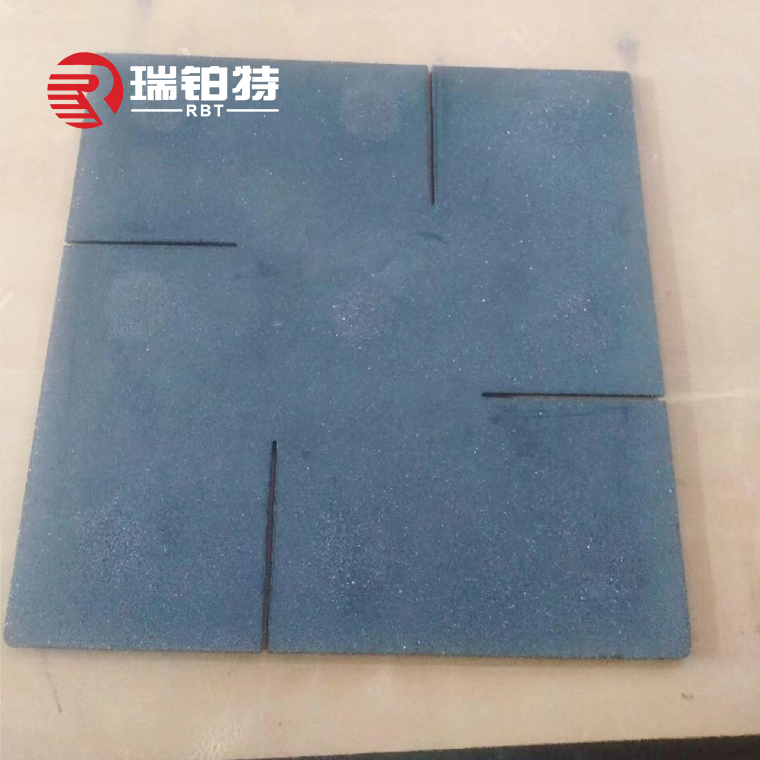

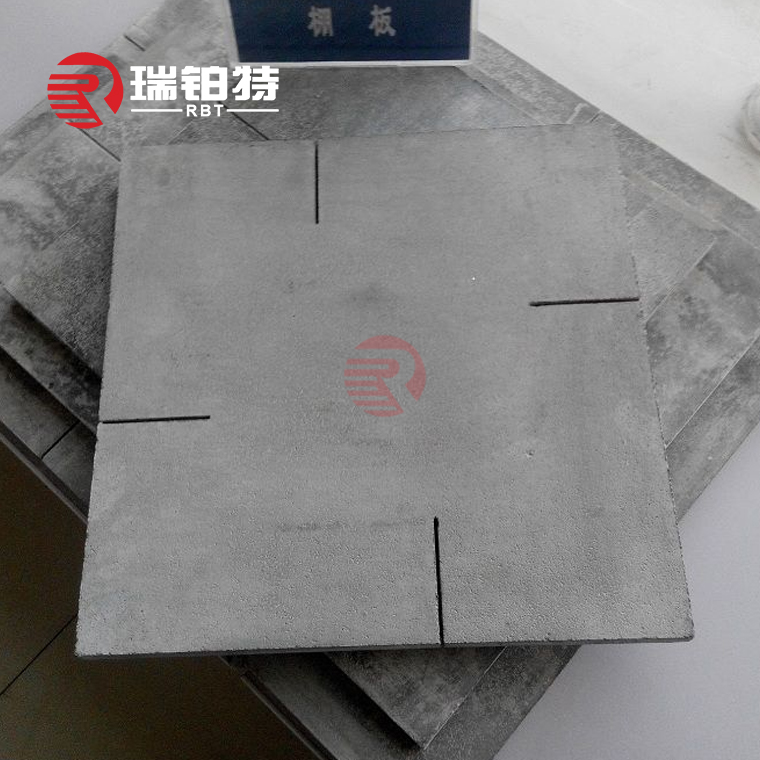

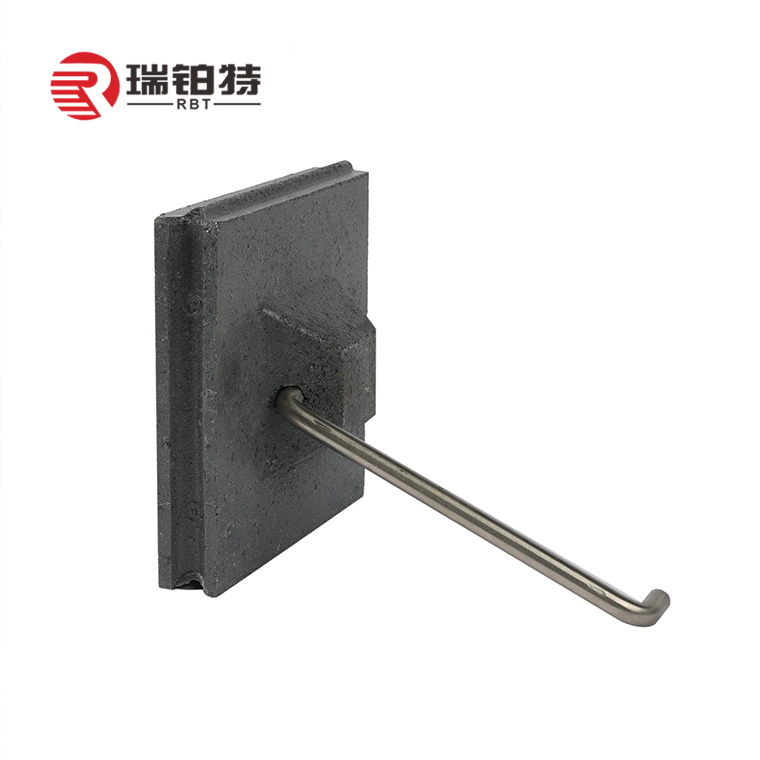

Poleiti ea carbide ea silicon:e sebediswang bakeng sa thepa e hanyetsang ka hara dionto, e nang le dibopeho tsa ho kopanya oxide.

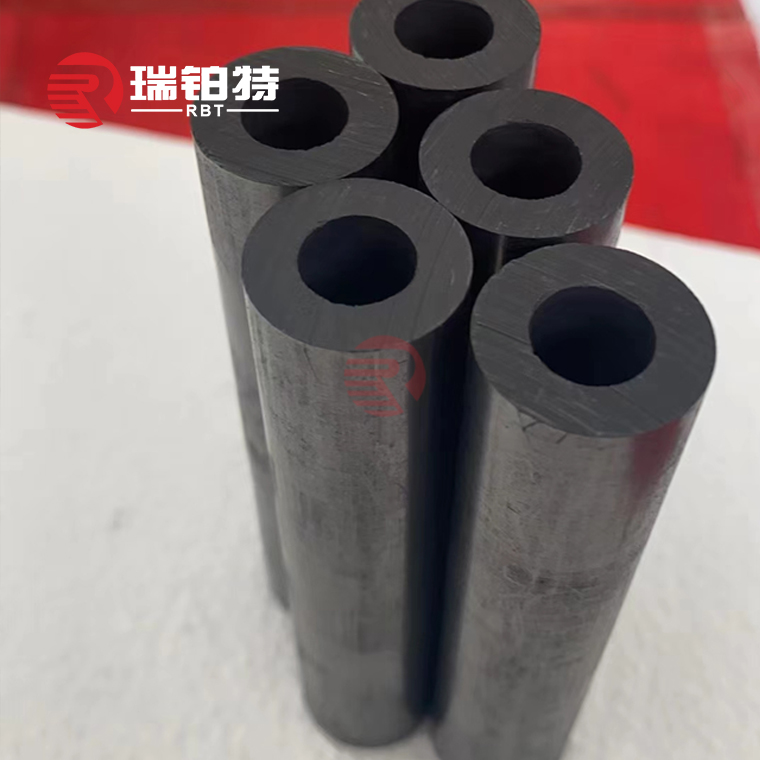

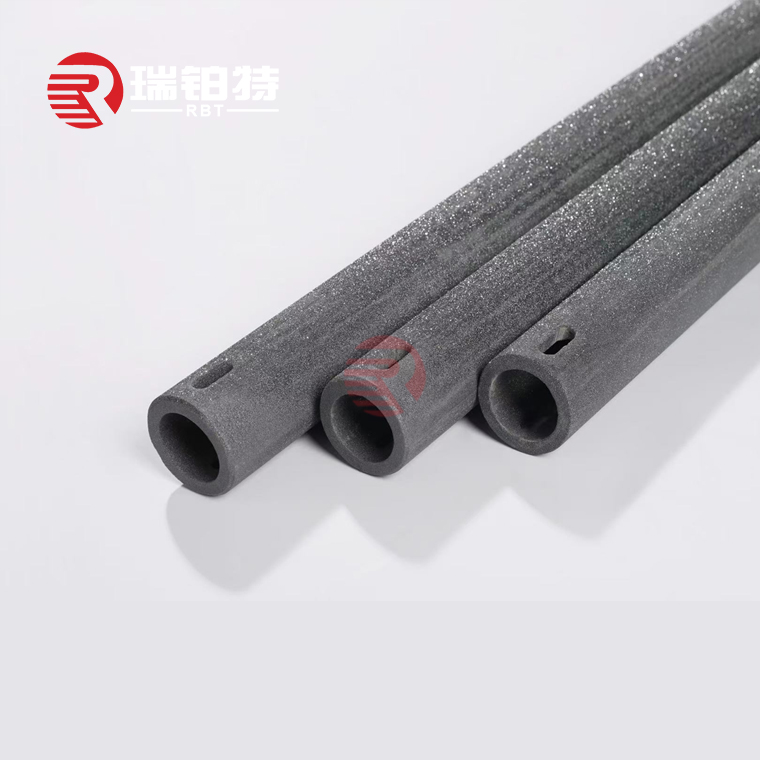

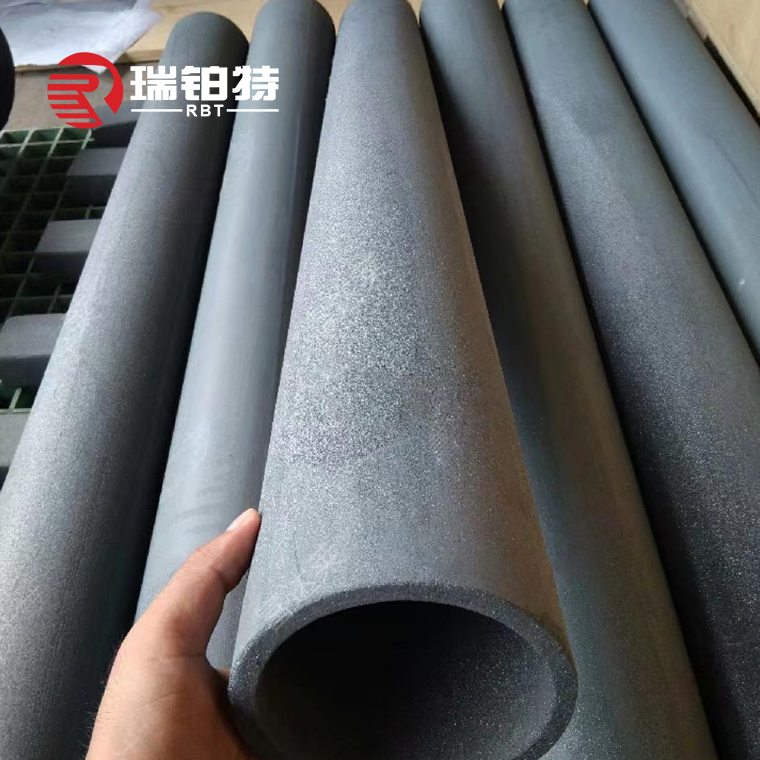

Phaephe ea carbide ea silicon:e sebediswang bakeng sa diphaephe le dijana dibakeng tse fapaneng tsa mocheso o phahameng.

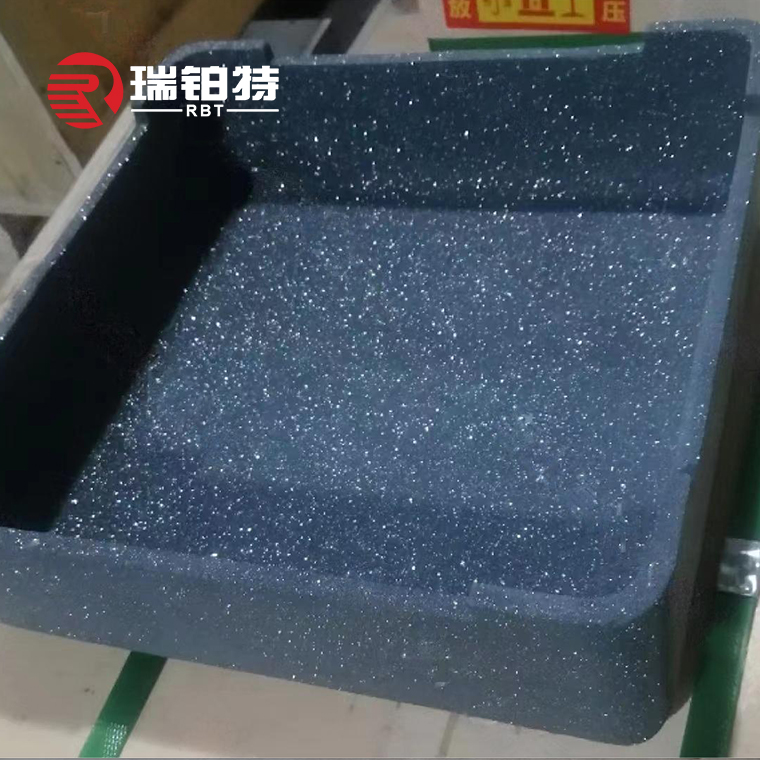

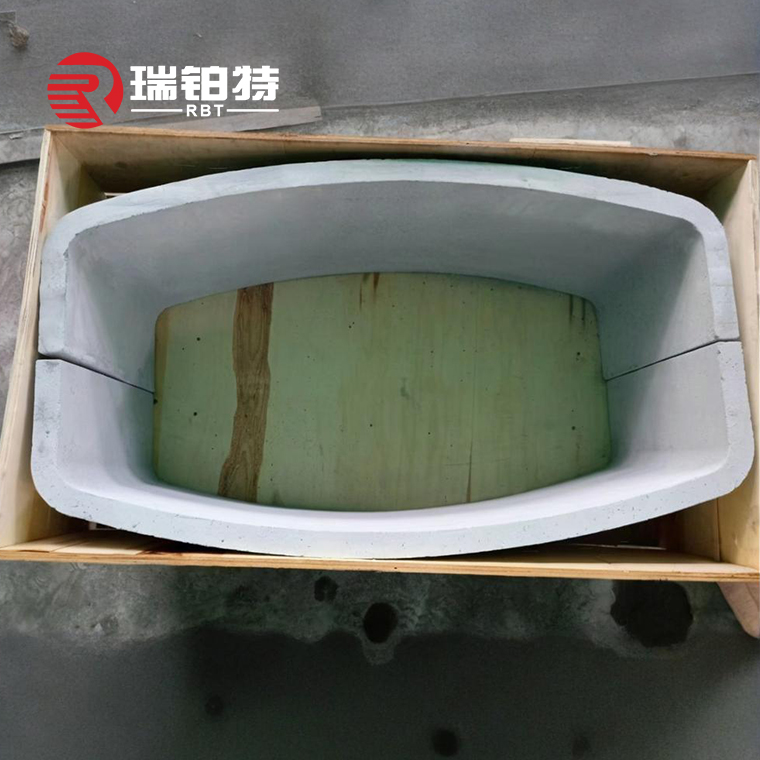

Sekoahelo sa silicon carbide le sagger:e sebelisetsoa ho qhibilihisa le ho boloka thepa ka mocheso o phahameng.

Lesale la tiiso la silicon carbide:e sebelisoa haholo masimong a likoloi, indasteri ea lifofane le ea lik'hemik'hale, 'me e ka boloka ts'ebetso e tšepahalang ea ho tiisa maemong a mocheso o phahameng le a khatello e phahameng.

Rolara ea khabide ea silicon:e sebediswa bakeng sa dionto tsa roller, e nang le dibopeho tsa ho thibela oxidation, matla a ho tenyetseha a mocheso o phahameng le bophelo bo bolelele ba tshebeletso.

Liphaephe tsa ho pholisa tsa silicon carbide:e sebelisetsoang sebaka sa ho pholisa sa li-roller kiln, e nang le khanyetso e ntle khahlanong le ho feteletseng

serame le mocheso.

Silicon carbide bunner nozzle:e sebelisetsoang lionto tse fapaneng tsa oli, khase le li-oven tse ling tsa indasteri, tse nang le litšobotsi tsa ho hanyetsa serame se feteletseng le mocheso, ho hanyetsa ho tsofala, ho hanyetsa mocheso o phahameng, jj.

Likarolo tse bōpehileng ka mokhoa o khethehileng tse entsoeng ka mokhoa o ikhethileng:Tlhahiso e ikhethileng ea likarolo tse fapaneng tse bōpehileng joaloka tse khethehileng ho latela litlhoko tsa bareki, tse kang lipoleiti tse bōpehileng joaloka tlhapi, lithupa tse leketlileng, likarolo tsa tšehetso, jj.

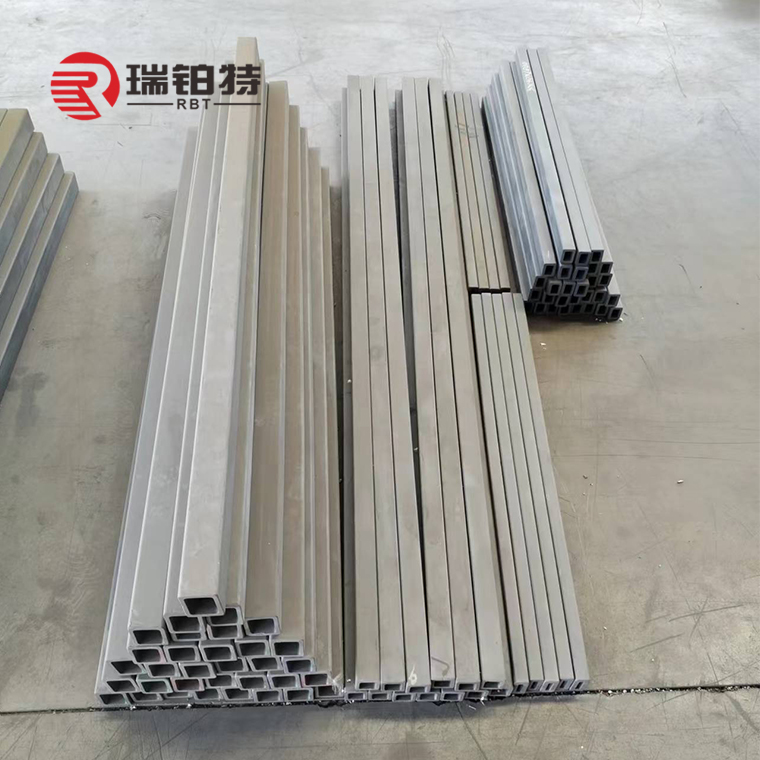

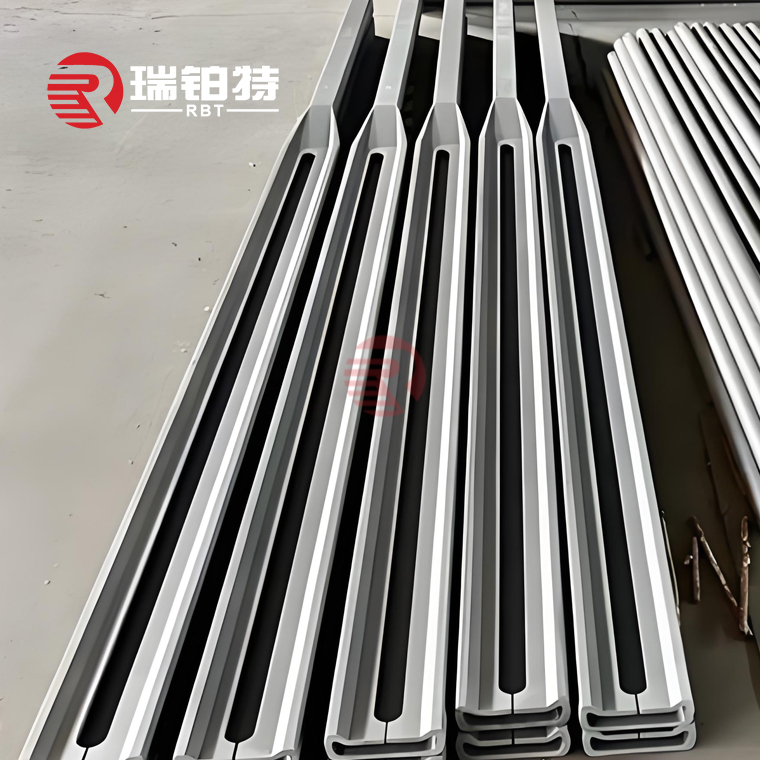

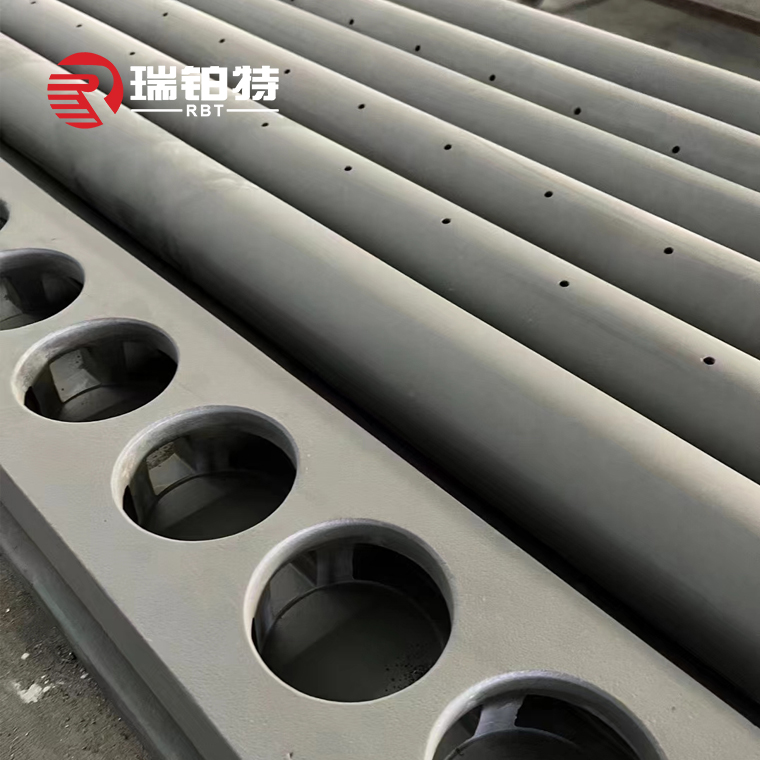

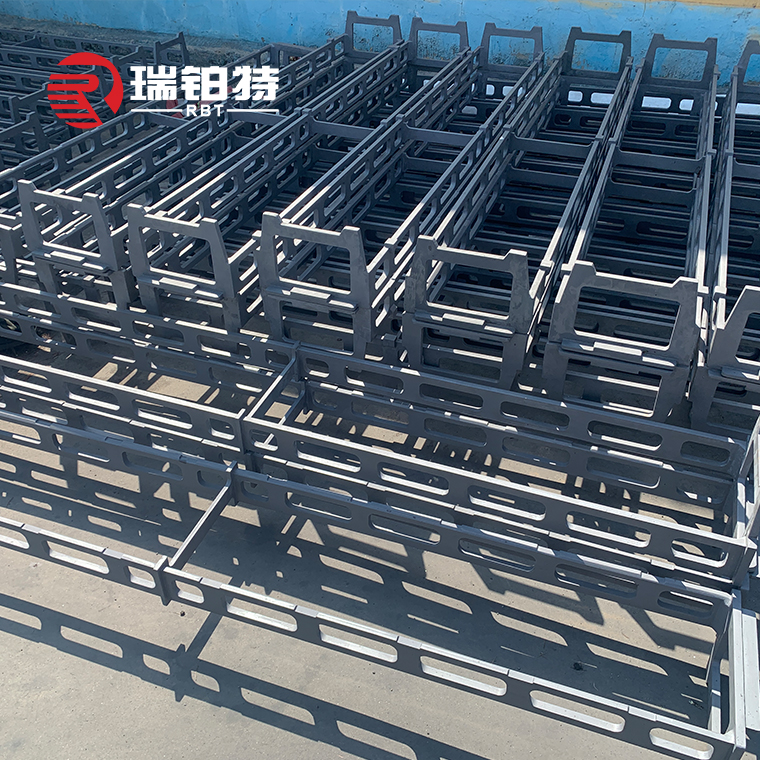

Litšoantšo tse qaqileng

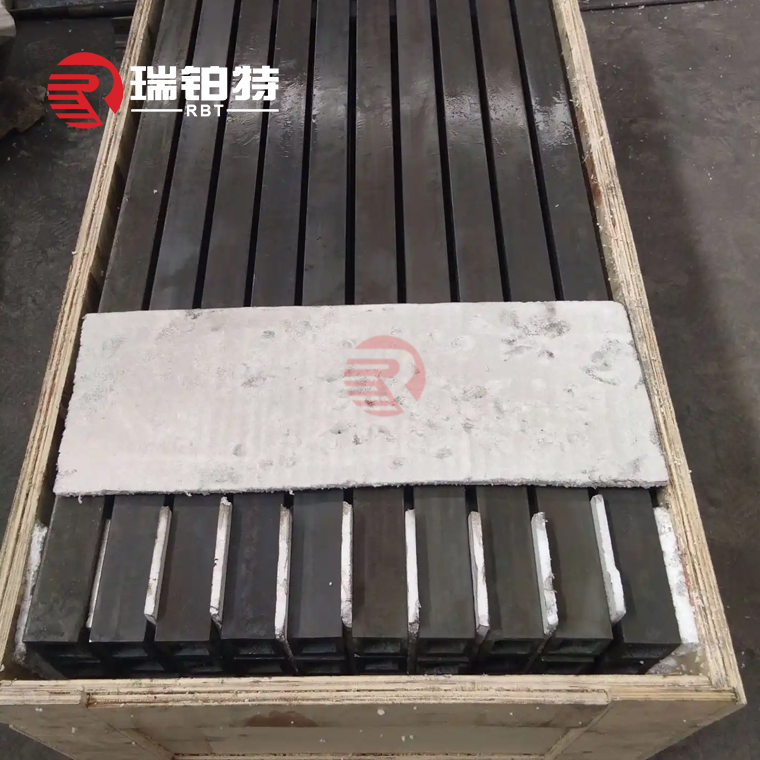

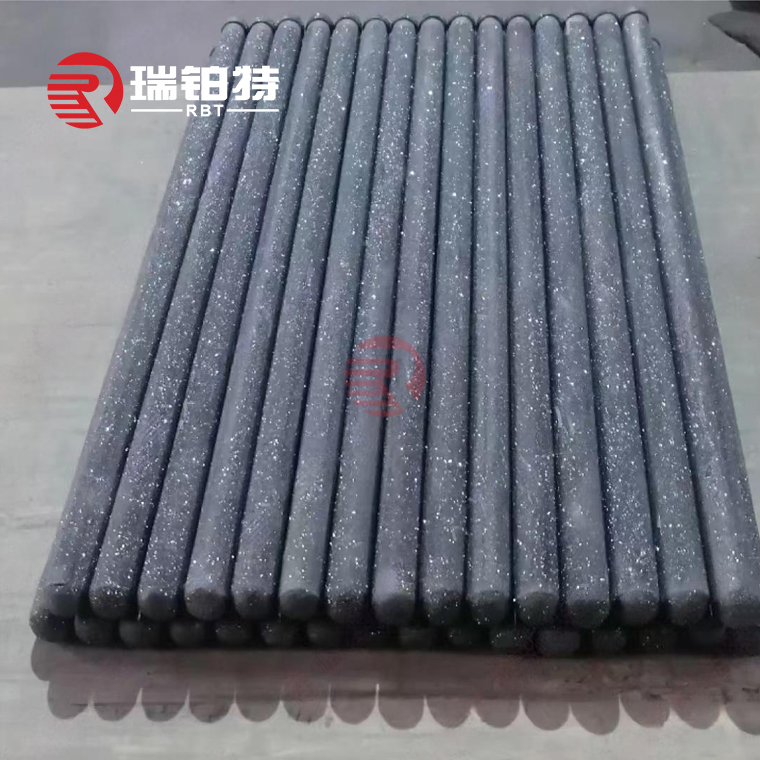

Silicon Carbide Beam

Sekepe sa Silicon Carbide Cantilever

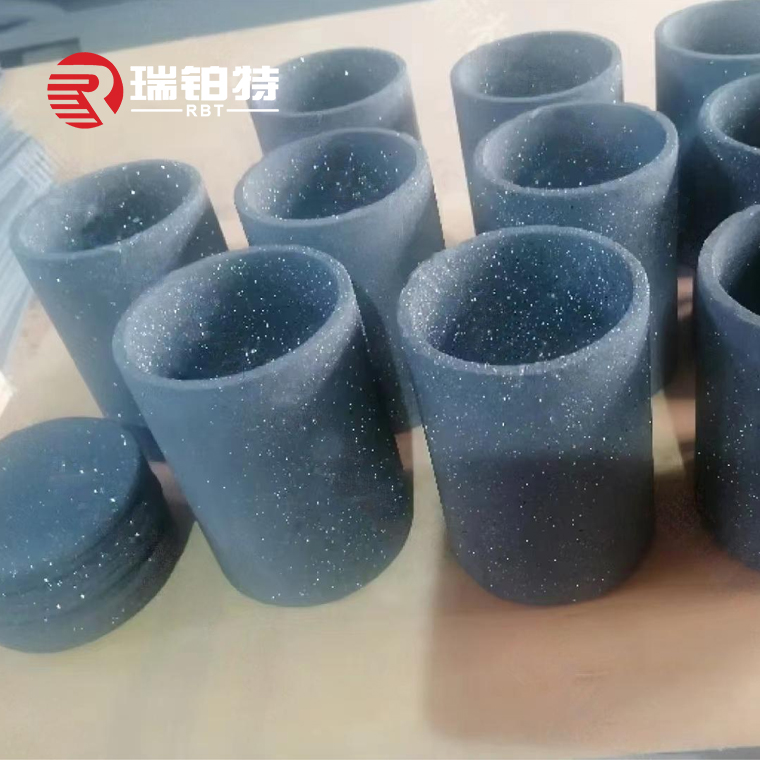

Nozzle ea Silicon Carbide

Silicon Carbide Burner Tube

Liphaephe tsa ho Pholisa tsa Silicon Carbide

Nozzle ea Silicon Carbide

Bracket ea Sekepe sa Silicon Carbide

Lesela le sa keneng

Sekepe sa Wafer sa Silicon Carbide

Lethathamo la Sehlahisoa

| Lihlahisoa tsa RBSiC(SiSiC) | ||

| Ntho | Yuniti | Lintlha |

| Mocheso o Moholo oa Kopo | ℃ | ≤1350 |

| Botenya | g/cm3 | ≥3.02 |

| Ho Bula Methapo e Meholo | % | ≤0.1 |

| Matla a ho Koba | Mpa | 250(20℃); 280(1200℃) |

| Modulus ea Elasticity | Gpa | 330(20℃); 300(1200℃) |

| Ho khanna ha mocheso | W/mk | 45 (1200℃) |

| Coefficient ea Katoloso ea Thermal | K-1*10-6 | 4.5 |

| Bothata ba Moh | | 9.15 |

| Asiti e sa keneleng Alkaline | | E babatsehang |

2. Lihlahisoa tsa carbide ea silicon e sintered e se nang khatello (Lihlahisoa tsa SSiC)

Lihlahisoa tsa carbide ea silicon e sintered e se nang khatello ke mofuta oa thepa ea ceramic ea theknoloji e phahameng e lokisitsoeng ka mokhoa oa ho sintering o se nang khatello. Karolo ea eona e ka sehloohong ke silicon carbide (SiC), 'me karolo e itseng ea litlatsetso ea eketsoa. Ka theknoloji e tsoetseng pele ea ceramic, e etsoa li-ceramic tse se nang masoba, tse se nang sekoli le tse se nang khatello ea maikutlo.

(1) Litšobotsi:

Khanyetso ea mocheso o phahameng:tšebeliso e tloaelehileng ho 1800℃;

Ho khanna ha mocheso o phahameng:e lekanang le ho khanna ha mocheso oa graphitethepa;

Ho thatafala ho hoholo:Bothata bo latela taemane le nitride ea cubic boron feela;

Khanyetso ea ts'enyeho:asiti e matla le alkali e matla ha li na mafome ho eona, 'me khanyetso ea eona ea mafome e betere ho feta tungsten carbide le aluminium oxide;

Boima bo bobebe:boima ba 3.10g/cm3, haufi le aluminium;

Ha ho na phetoho:coefficient e nyane haholo ea katoloso ea mocheso,

E hanela ho thothomela ha mocheso:thepa e ka mamella liphetoho tse potlakileng tsa mocheso, ho thothomela ha mocheso, ho phola le ho futhumatsa ka potlako, 'me e na le ts'ebetso e tsitsitseng.

(2) Lihlahisoa tse ka Sehloohong:

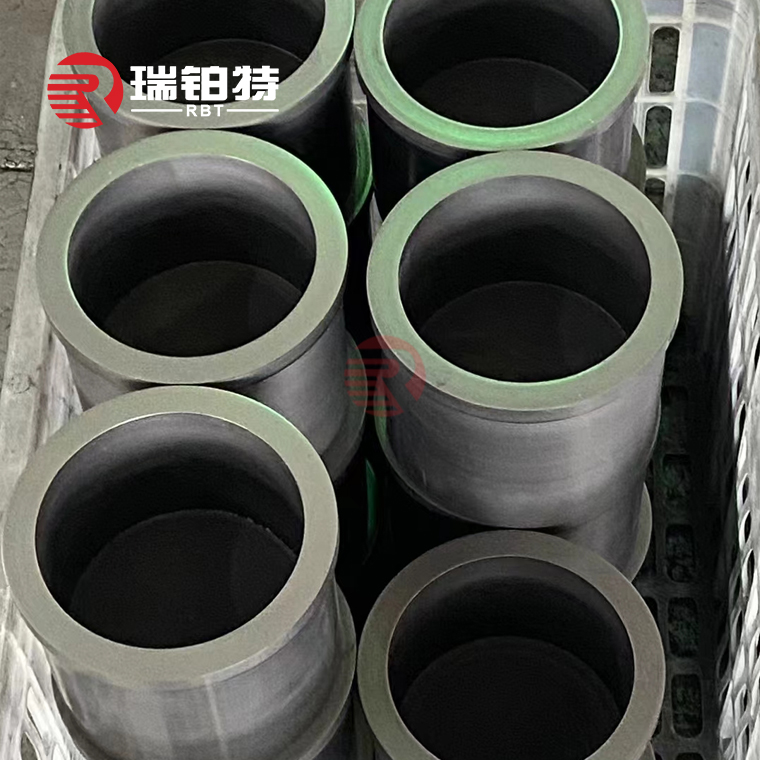

Masale a tiiso:Lihlahisoa tsa silicon carbide tse sintered tse se nang khatello hangata li sebelisoa ho etsa masale a tiiso a sa tsofaleng le a sa senyeheng le a sa senyeheng.

Likarolo tsa mechini:Ho kenyeletsoa le li-bearing tse mocheso o phahameng, litiiso tsa mechini, li-nozzle, li-valve tsa pneumatic, 'mele ea pompo, lisebelisoa, jj.

Lisebelisoa tsa lik'hemik'hale:E sebelisoa ho etsa liphaephe tse sa senyeheng, litanka tsa polokelo, li-reactor le litiiso.

Lisebelisoa tsa elektroniki:Indastering ea motlakase, carbide ea silicon e sintered e se nang khatello e sebelisoa ho etsa li-resistor tsa mocheso o phahameng, likarolo tsa ho futhumatsa tsa motlakase le li-switch tsa motlakase o phahameng.

Thepa ea ka tlung ea kiln:Tse kang diforeimi tsa sebopeho tse jarang mojaro, dirolara, dinotlolo tsa malakabe, diphaephe tse phodisang, jj. ka diontong tsa thanele, diontong tsa shuttle le diontong tse ding tsa indasteri.

Litšoantšo tse qaqileng

Lesale la Seti sa Silicon Carbide

Pipe ea Carbide ea Silicone

Li-Liner tsa Silicon Carbide

Silicon Carbide Beam

Poleiti ea Carbide ea Silicone

Moqomo oa ho Sila oa Silicon Carbide

Lethathamo la Sehlahisoa

| Lihlahisoa tsa SSiC | ||

| Ntho | Yuniti | Sephetho |

| Bothata | HS | ≥115 |

| Sekhahla sa ho ba le masoba | % | <0.2 |

| Botenya | g/cm3 | ≥3.10 |

| Matla a Khatello | Mpa | ≥2500 |

| Matla a ho Koba | Mpa | ≥380 |

| Katoloso e lekanang | 10-6/℃ | 4.2 |

| Dikahare tsa SiC | % | ≥98 |

| Si ea mahala | % | <1 |

| Modulus e tenyetsehang | Gpa | ≥410 |

| Mocheso o Moholo oa Kopo | ℃ | 1400 |

3. Sehlahisoa sa silicon carbide se sebedisitsweng botjha (Dihlahiswa tsa RSiC)

Lihlahisoa tsa Silicon Carbide tse nchafalitsoeng ke sehlahisoa se hanyetsang se entsoeng ka silicon carbide e hloekileng haholo e le thepa e tala. Tšobotsi ea eona e ka sehloohong ke hore ha ho na karolo ea bobeli 'me e entsoe ka 100% α-SiC.

(1) Litšobotsi:

Boima bo phahameng:Bothata ba eona bo latela daemane feela, 'me e na le matla a phahameng haholo a mechini le ho tiea.

Ho hanyetsa mocheso o phahameng:E ka boloka ts'ebetso e tsitsitseng tikolohong ea mocheso o phahameng 'me e loketse mocheso oa 1350 ~ 1600℃.

Khanyetso e matla ea ts'enyeho:E na le khanyetso e phahameng ea ts'enyeho ho mefuta e fapaneng ea mecha ea phatlalatso 'me e ka bolokathepa ea mechini ka nako e telele libakeng tse fapaneng tse senyang.

Ho hanyetsa oxidation hantle:E na le khanyetso e ntle ea oxidation 'me e ka sebetsa ka botsitso mochesong o phahameng.

Ho hanyetsa mocheso hantle:E sebetsa hantle tikolohong e nang le liphetoho tse potlakileng tsa mocheso 'me e loketse libaka tsa ho tšoha ha mocheso.

Ha ho na ho fokotseha ha moriri nakong ea ho hema:Ha e fokotsehe nakong ea ts'ebetso ea ho sila, 'me ha ho na khatello e setseng e tla hlahisoa ho baka ho fetoha kapa ho petsoha ha sehlahisoa. E loketse ho lokisoa ha likarolo tse nang le libopeho tse rarahaneng le ho nepahala ho hoholo.

(2) Lihlahisoa tse ka Sehloohong:

Thepa ea thepa ea ka tlung ea kiln:Haholo-holo e sebelisoa bakeng sa thepa ea ka tlung ea ontong, e na le melemo ea ho boloka matla, ho eketsa molumo o sebetsang oa ontong, ho khutsufatsa potoloho ea ho besa, ho ntlafatsa katleho ea tlhahiso ea ontong le melemo e phahameng ea moruo.

Li-nozzle tsa bunner:E ka sebelisoa e le lihlooho tsa li-nozzle tsa ho tuka 'me e loketse libaka tse nang le mocheso o phahameng.

Liphaephe tsa ho futhumatsa mahlaseli a ceramic:Liphaephe tsena tsa ho futhumatsa li sebelisa monyetla oa botsitso ba mocheso o phahameng le ho hanyetsa mafome ha silicon carbide e nchafalitsoeng 'me li loketse lits'ebetso tse fapaneng tsa indasteri tsa mocheso o phahameng.

Liphaephe tsa tšireletso ea likarolo:Haholo-holo lifonong tsa sepakapaka, lihlahisoa tsa silicon carbide tse entsoeng hape li sebelisoa e le liphaephe tsa tšireletso ea likarolo tse nang le mocheso o phahameng le ho hanyetsa mafome.

Mebele ea pompo ea mocheso o phahameng, li-impeller tsa pompo, li-bearing, matlo a enjene:Masimong a likoloi, lifofane le liindasteri tsa sesole, thepa ea silicon carbide e entsoeng hape e etsoa ka har'a lipompo tsa mocheso o phahameng, li-impeller tsa pompo, li-bearings le matlo a enjene, jj., li sebelisa monyetla oa ho hanyetsa mocheso o phahameng, ho hanyetsa asiti le alkali le ho hanyetsa ho tsofala.

Litšoantšo tse qaqileng

Likarolo tse bōpehileng joaloka Silicon Carbide

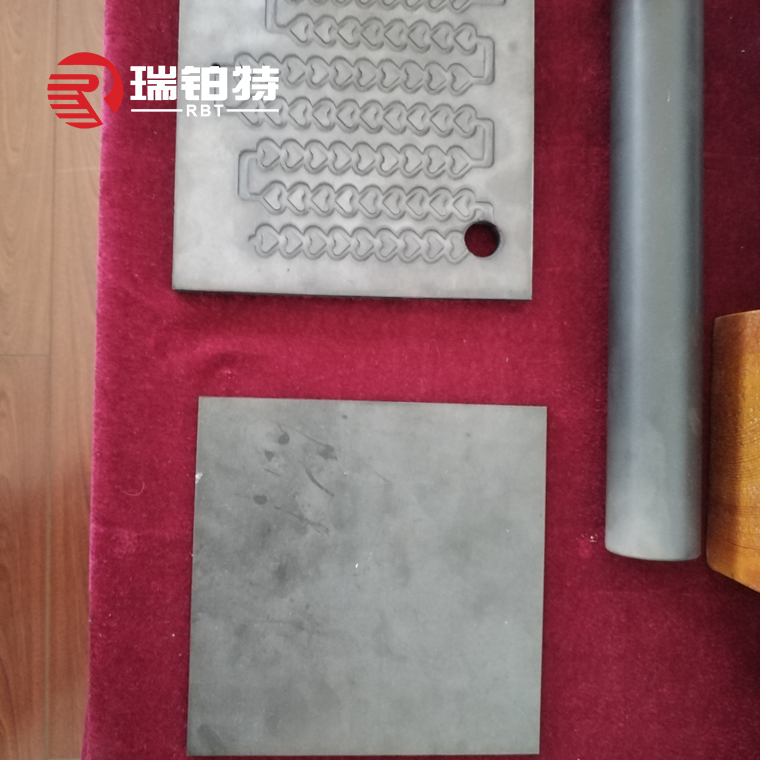

Poleiti ea Carbide ea Silicone

Roller ea Carbide ea Silicon

Silicon Carbide Beam

Liphaephe tsa Tšireletso ea Carbide ea Silicon

Thepa ea ka tlung ea kiln

Sagger ea Silicon Carbide

Sebopi sa Silicon Carbide

Poleiti ea Carbide ea Silicone

Sesebelisoa sa ho lokisa khabone sa silicon

Pipe ea Carbide ea Silicone

Setofo sa Silicon Carbide

4. Lihlahisoa tsa carbide tsa silicon tse kopantsoeng le nitride tsa silicon (Lihlahisoa tsa NSiC)

Lihlahisoa tsa carbide ea silicon e kopantsoeng le nitride ke thepa e entsoeng ka ho eketsa motsoako oa SiC ho phofo ea silicon ea indasteri, e arabelang le naetrojene mochesong o phahameng ho hlahisa Si3N4 le ho kopana ka thata le likaroloana tsa SiC.

(1) Litšobotsi:

Boima bo phahameng:Bothata ba Mohs ba dihlahiswa tsa silicon carbide tse tlamilweng ka silicon nitride bo ka ba 9, bo latela daemane feela, mme ke thepa e nang le bothata bo phahameng hara disebediswa tse seng tsa tshepe.

Matla a mocheso o phahameng:Maemong a mocheso o phahameng oa 1200-1400℃, matla le ho thatafala ha thepa ha li fetohe, 'me mocheso o phahameng ka ho fetisisa oa tšebeliso o sireletsehileng o ka fihla ho 1650-1750℃.

Botsitso ba mocheso:E na le coefficient e nyane ea katoloso ea mocheso le conductivity e phahameng ea mocheso, ha ho bonolo ho hlahisa khatello ea mocheso, e na le botsitso bo botle ba ho tšoha ha mocheso le ho hanyetsa ho thekesela, 'me e loketse libaka tse batang haholo le tse chesang haholo.

Botsitso ba lik'hemik'hale:Ha e na mafome ebile ha e na oxidation, 'me e ka lula e tsitsitse libakeng tse fapaneng tsa lik'hemik'hale.

Ho hanyetsa ho apara:E na le khanyetso e ntle ea ho robeha 'me e loketse lits'ebetso tse fapaneng tsa indasteri tse nang le ho robeha ho matla.

(2) Lihlahisoa tse ka Sehloohong:

Litene tse halefileng:e sebediswa haholo ho aluminium ya electrolytic, diontong tsa ho phatloha ha tshepe, diontong tsa arc tse kenelletseng ka metsing le diindastering tse ding, ka dibopeho tsa ho hanyetsa mocheso o phahameng, ho hanyetsa mafome, le ho hanyetsa kgoholeho ya mobu.

Thepa ea ka tlung ea setofo:e sebelisetsoang mabili a silang a letsopa, porcelain ea motlakase e nang le motlakase o phahameng, li-kiln tsa indasteri, jj., tse nang le bokhoni bo botle ba ho jara mojaro le ho hanyetsa mocheso o phahameng.

Lihlahisoa tse bōpehileng ka tsela e khethehileng:e sebediswang ho lahla metallurgical e seng ya ferrous, matla a mocheso, diontong tsa arc tse ka tlasa metsi le diindastering tse ding, ka dibopeho tsa ho hanyetsa ho tsofala le ho hanyetsa mocheso o phahameng.

Likarolo tse halefisang:ho kenyeletsoa liphaephe tsa tšireletso ea thermocouple, liphaephe tse phahamisang, matsoho a futhumatsang, jj., tse sebelisoang liontong tse nang le mocheso o phahameng le libakeng tse fapaneng tsa leholimo, tse nang le phallo e phahameng ea mocheso le ho hanyetsa ho bola.

Litšoantšo tse qaqileng

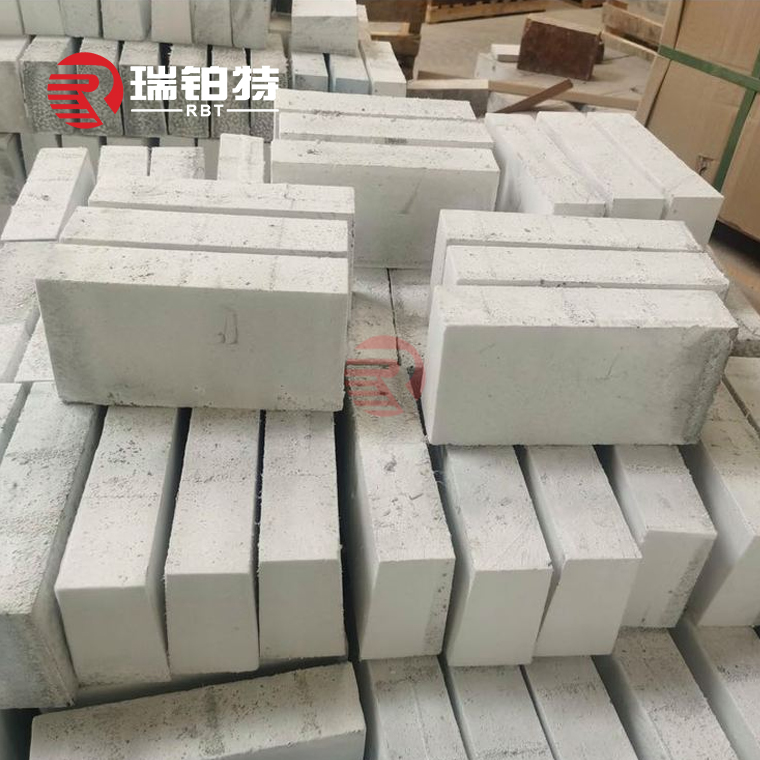

Poleiti e bōpehileng joaloka Silicon Carbide

Poleiti e bōpehileng joaloka Silicon Carbide

Poleiti e bōpehileng joaloka Silicon Carbide

Poleiti e bōpehileng joaloka Silicon Carbide

Poleiti e bōpehileng joaloka Silicon Carbide

Liphaephe tsa Mahlaseli a Silicon Carbide

Pipe ea Carbide ea Silicone

Poleiti e bōpehileng joaloka Silicon Carbide

Likarolo tse bōpehileng joaloka Silicon Carbide

Liphaephe tsa Tšireletso ea Carbide ea Silicon

Poleiti ea Carbide ea Silicone

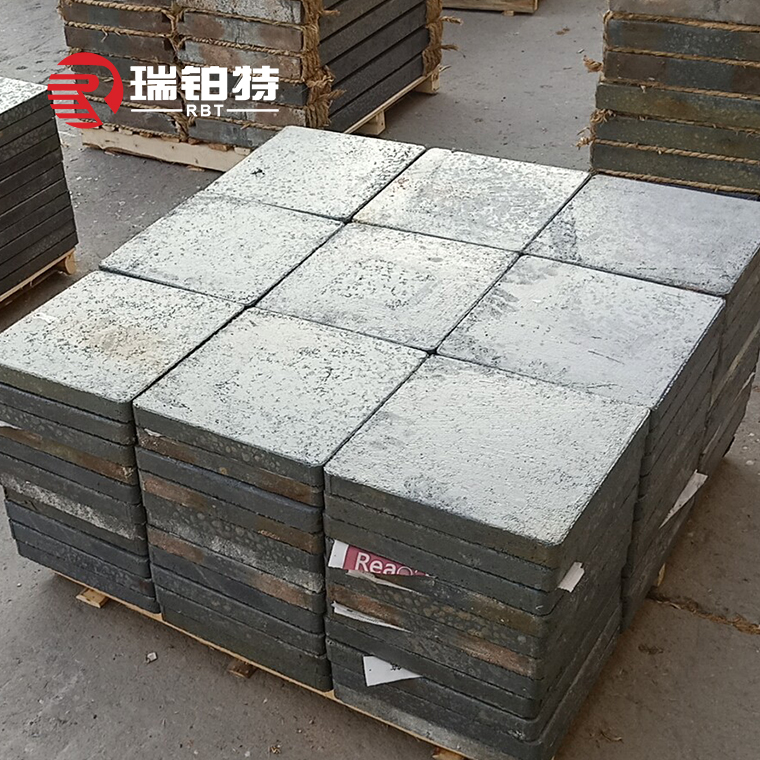

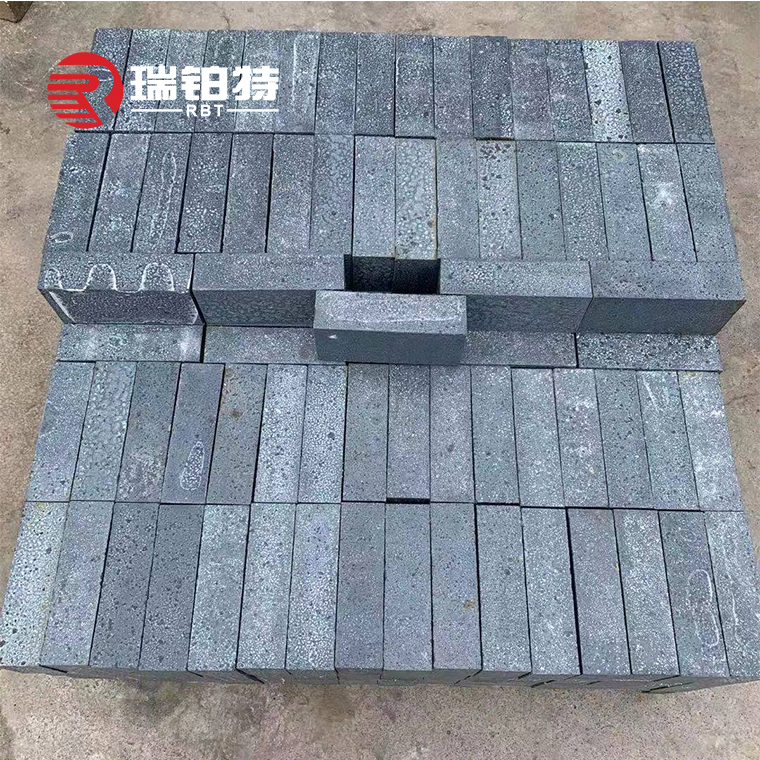

Litene tsa Silicon Carbide

5. Lihlahisoa tsa silicon carbide tse kopantsoeng le oxide

Lihlahisoa tsa carbide ea silicon e kopantsoeng le oxide li etsoa ka ho kopanya likaroloana tsa silicon carbide le phofo ea oxide (joalo ka silicon dioxide kapa mullite), ho tobetsa le ho sila mochesong o phahameng. Tšobotsi ea eona ke hore nakong ea ts'ebetso ea sila le ts'ebeliso, filimi ea oxide e phuthetsoe holim'a likaroloana tsa silicon carbide, e leng se ntlafatsang haholo khanyetso ea oxidation le matla a mocheso o phahameng.

E na le litšobotsi tsa matla a ho tenyetseha a mocheso o phahameng, botsitso bo botle ba ho sisinyeha ha mocheso, ho tsamaisa mocheso o phahameng, ho hanyetsa ho tsofala le ho hanyetsa ka matla khoholehong e fapaneng ea sepakapaka, 'me ke thepa e loketseng ea ho boloka matla bakeng sa lionto tsa indasteri.

(2) Lihlahisoa tse ka Sehloohong:

Lihlahisoa tsa silicon carbide tse kopantsoeng le silicon dioxide:Sehlahisoa sena se sebelisa silicon dioxide (SiO2) e le mohato oa ho tlama. Hangata 5% ~ 10% ea phofo ea silicon dioxide kapa phofo ea quartz e kopanngoa le likaroloana tsa silicon carbide (SiC). Ka linako tse ling ho eketsoa phallo. Kamora ho hatelloa le ho etsoa, e chesoa ka ontong e akaretsang. Tšobotsi ea eona ke hore nakong ea ts'ebetso ea ho thunya le ho sebelisa, filimi ea silicon dioxide e phuthetsoe holim'a likaroloana tsa silicon carbide, e leng se ntlafatsang haholo khanyetso ea oxidation le matla a mocheso o phahameng. Sehlahisoa sena se sebelisoa haholo lishelefong tsa ontong bakeng sa ho besa porcelain (>1300℃), 'me bophelo ba eona ba ts'ebeletso bo feta

e imenne habeli ea lihlahisoa tsa silicon carbide tse kopantsoeng ka letsopa.

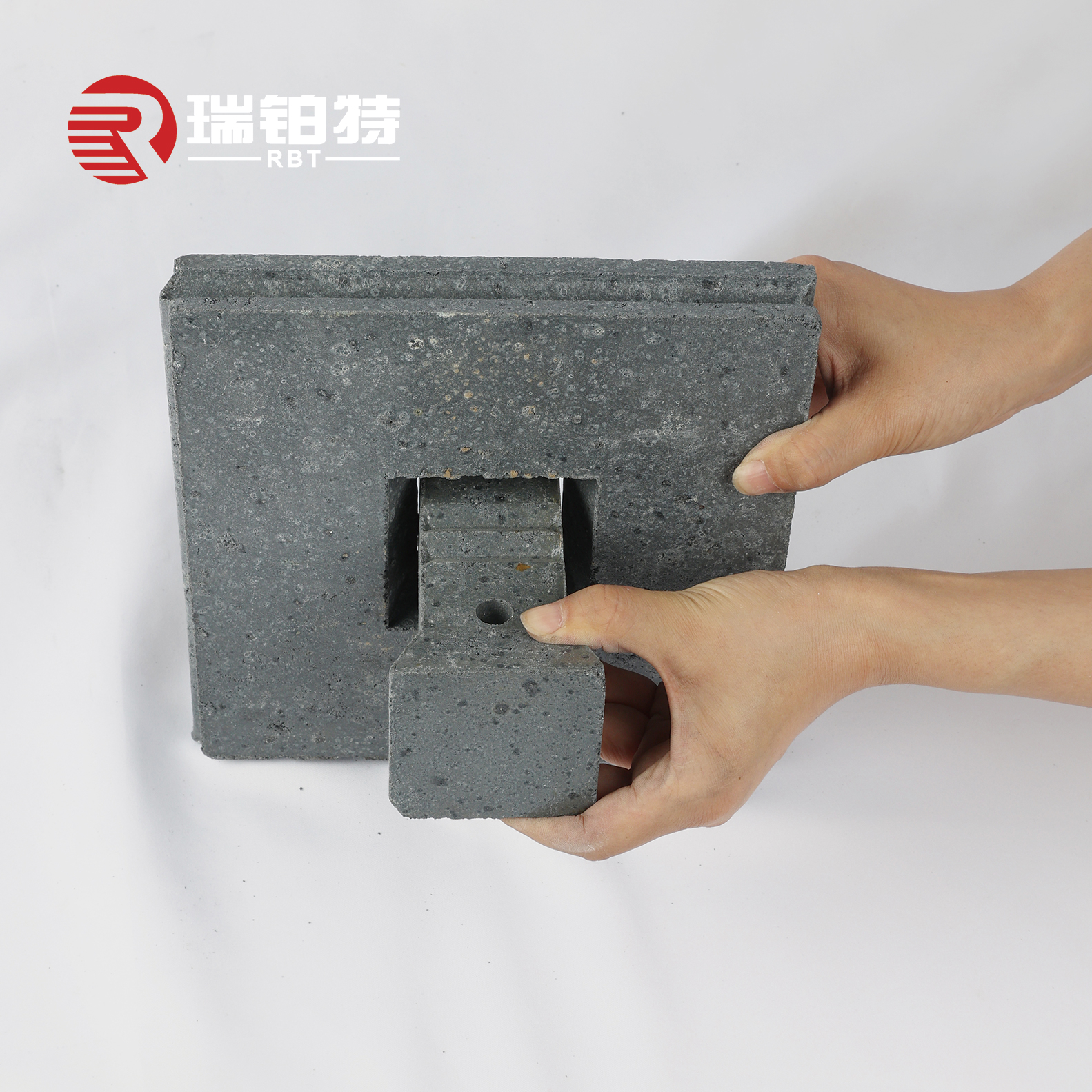

Lihlahisoa tsa carbide ea silicon e kopantsoeng ka bongata:Sehlahisoa sena se eketsa phofo ea α-Al2O3 le phofo ea silicon dioxide metsoakong ea carbide ea silicon. Kamora ho tobetsa le ho bopa, Al2O3 le SiO2 lia kopanngoa ho etsa mullite nakong ea ts'ebetso ea ho sinter. Nakong ea ts'ebeliso, silicon dioxide e entsoeng ke oxidation ea silicon carbide e etsa mullite ka karolo e itseng le Al2O3. Thepa ena e na le botsitso bo botle ba mocheso 'me e sebelisoa haholo tlhahisong ea li-sagger tsa porcelain le lishelefo.

Litšoantšo tse qaqileng

Poleiti ea Carbide ea Silicone

Litene tsa Silicon Carbide

Poleiti ea Carbide ea Silicone

Phaephe ea SiC Microcrystalline

Boto ea SiC Microcrystalline

Boto ea SiC Microcrystalline

Boemo ba Khoebo

Shandong Robert New Material Co., Ltd.e fumaneha Motseng oa Zibo, Profinseng ea Shandong, Chaena, e leng setsi sa tlhahiso ea thepa e hanyetsang. Re khoebo ea sejoale-joale e kopanyang lipatlisiso le nts'etsopele, tlhahiso, thekiso, moralo le kaho ea ontong, theknoloji le thepa e hanyetsang kantle ho naha. Re na le lisebelisoa tse felletseng, theknoloji e tsoetseng pele, matla a tekheniki a matla, boleng bo botle ba sehlahisoa, le botumo bo botle. Feme ea rona e akaretsa lihekthere tse fetang 200 'me tlhahiso ea selemo le selemo ea thepa e hanyetsang e bōpehileng joaloka e ka ba lithane tse 30000 'me thepa e hanyetsang e sa bōpehang joaloka e hanyetsang ke lithane tse 12000.

Lihlahisoa tsa rona tse ka sehloohong tsa thepa e hanyetsang li kenyelletsa:thepa e hanyetsang alkaline; thepa e hanyetsang silicon ea aluminium; thepa e sa bōpehang e hanyetsang; thepa e thibelang mocheso e thibelang mocheso; thepa e khethehileng e thibelang; thepa e sebetsang e thibelang bakeng sa litsamaiso tse tsoelang pele tsa ho lahla.

Lipotso Tse Botsoang Khafetsa

Na u hloka thuso? Etsa bonnete ba hore u etela liforamo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, fektheri ea rona e ikhethile ka ho hlahisa thepa e hanyetsang ka lilemo tse fetang 30. Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ea kamora thekiso.

Bakeng sa ts'ebetso e 'ngoe le e 'ngoe ea tlhahiso, RBT e na le sistimi e felletseng ea QC bakeng sa sebopeho sa lik'hemik'hale le thepa ea 'mele. 'Me re tla leka thepa, 'me setifikeiti sa boleng se tla romelloa le thepa. Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho latela bongata, nako ea rona ea ho tlisa thepa e fapane. Empa re tšepisa ho e romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ehlile, re fana ka disampole tsa mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e ntle ka ho fetisisa ho latela boemo ba hau.

Re ntse re etsa thepa e hanyetsang mocheso ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le boiphihlelo bo bongata, re ka thusa bareki ho rala li-kiln tse fapaneng le ho fana ka tšebeletso ea ho emisa hang feela.