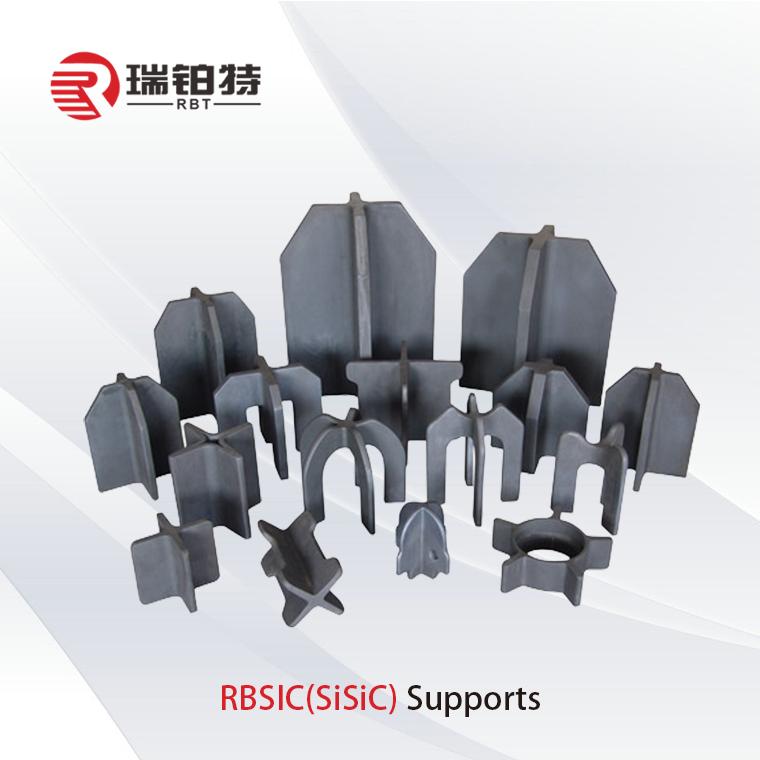

Lihlahisoa tsa RBSiC (SiSiC).

Tlhahisoleseding ya Sehlahiswa

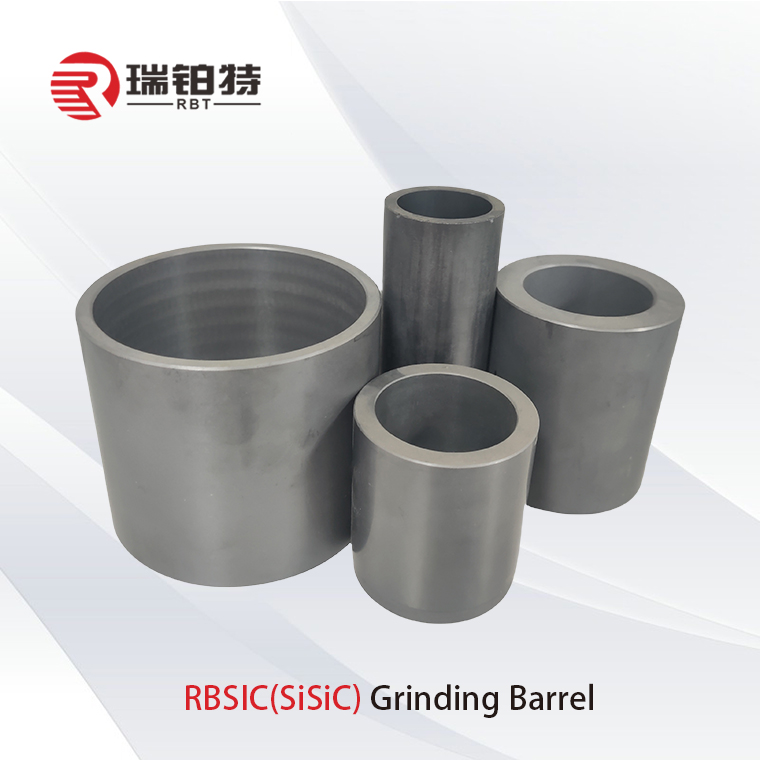

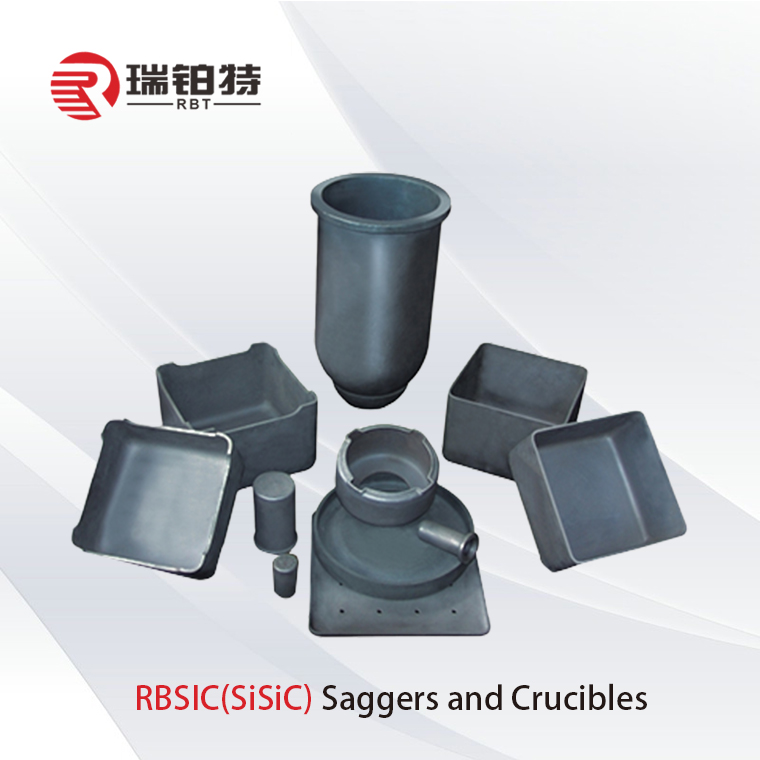

| SehlahisoaLebitso | Lihlahisoa tsa RBSIC(SiSiC)(Reactive Sintering Silicon Carbide Products) |

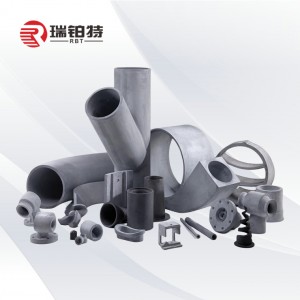

| Tlhaloso | Siliconized SiC ke karabelo ea silicon e kopantsoeng ka mokhoa o ts'oanang le ho kenngoa ka likaroloana tse ntle tsa SiC, phofo ea carbon le li-additives ka tekanyo ea ho hlahisa SiC le ho kopana le SiC, silicon e feteletseng e tlatsa likheo ho fumana lisebelisoa tsa ceramic tse teteaneng haholo. |

| Sebopeho | Thepa ea siliconized silicon carbide e na le letoto la boleng ba mantlha le litšoaneleho tse kang matla a phahameng, boima bo feteletseng, ho se mamelle mocheso, ho hanyetsa kutu, khanyetso ea oxidation ea mocheso, conductivity e phahameng ea mocheso, coefficient e tlase ea ho atolosoa ha mocheso, khanyetso e tlase. mocheso o phahameng joalo-joalo. Lihlahisoa tse ngata li ka etsoa ho eona tse kang maballo, lirolara, liphaephe tsa moea tse pholileng, li-tubes tse sireletsang banyalani ka mocheso, li-tubes tse lekanyang mocheso, likarolo tse koalang le likarolo tse khethehileng tse bōpehileng. |

Index ea Lihlahisoa

| Ntho | Yuniti | Lintlha |

| Mocheso o Phahameng oa Kopo | ℃ | ≤1380 |

| Botenya | g/cm3 | ~3.02 |

| Open Porosity | % | ≤0.1 |

| Matla a Kobehang | Mpa | 250(20℃);280(1200℃) |

| Modulus ea Elastictiy | GPA | 330(20℃);300(1200℃) |

| Thermal Conductivity | W/mk | 45(1200℃) |

| Mocheso oa Katoloso ea Mocheso | K-1*10-6 | 4.5 |

| Bothata ba Moh | | 9.15 |

| Acid Alkaline-Bopaki | | E kgabane |

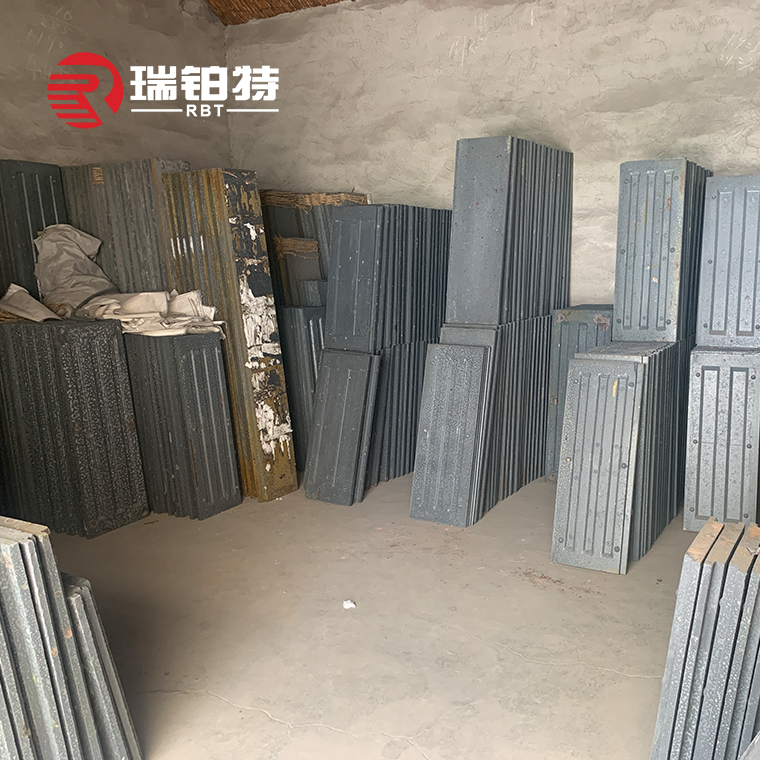

Lintlha Litšoantšo

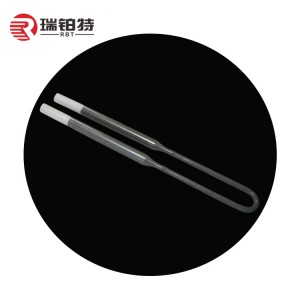

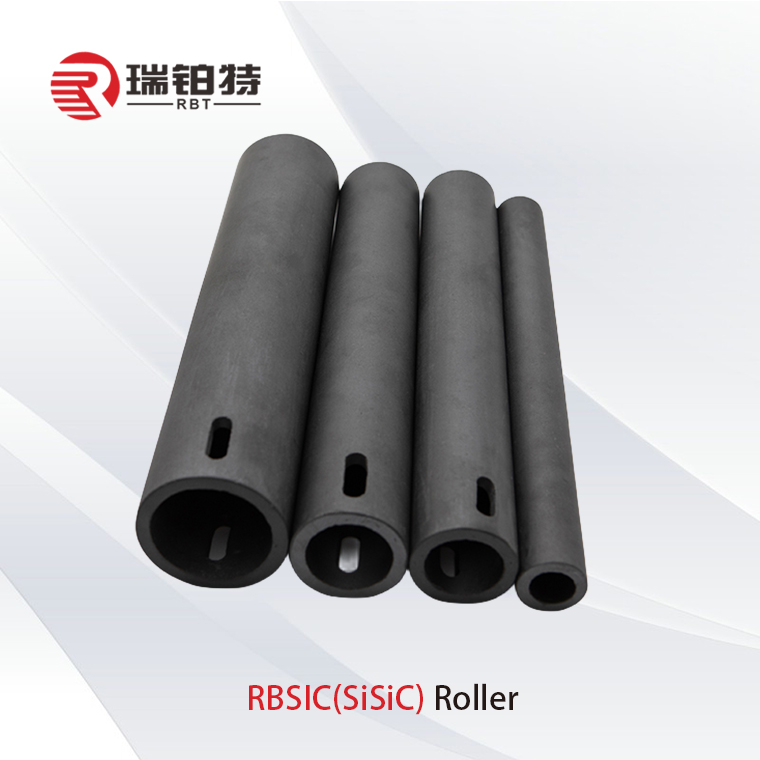

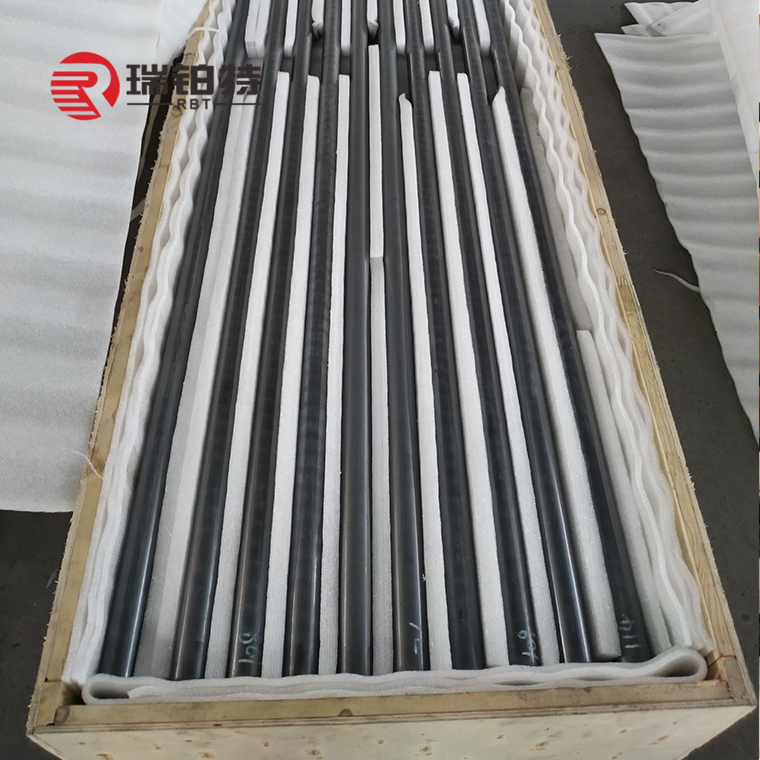

Sebopeho:Tšireletso e ntle ea lik'hemik'hale tsa corrosion ea silicon carbide roll rod e etsa hore e khone ho sebetsa nako e telele tikolohong e matla e senyang ea lithium kiln ea motlakase, 'me e na le bophelo bo bolelele.

| Ho Bearing Capacity of RBSic(SiSiC) Rollers | |||

| BoholoeaKarolo(mm) | LerakoBotenya(mm) | Tsepamisitsoe maikutloE ea kenya(kg.m/L) | Ka mokhoa o ts'oanangE ajoaE ea kenya(kg.m/L) |

| 30 | 5 | 43 | 86 |

| 35 | 5 | 63 | 126 |

| 35 | 6 | 70 | 140 |

| 38 | 5 | 77 | 154 |

| 40 | 6 | 97 | 197 |

| 45 | 6 | 130 | 260 |

| 50 | 6 | 167 | 334 |

| 60 | 7 | 283 | 566 |

| 70 | 7 | 405 | 810 |

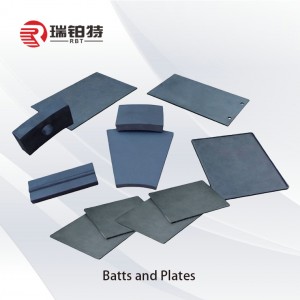

Kopo:Sebōpi sa ho sesa, sebōpi sa kotopo, sebōpi sa lirolara, le lintho tse ling tsa liindasteri tse nang le thepa e tsamaisang teraka.

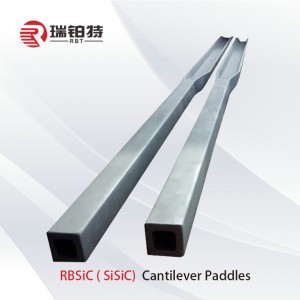

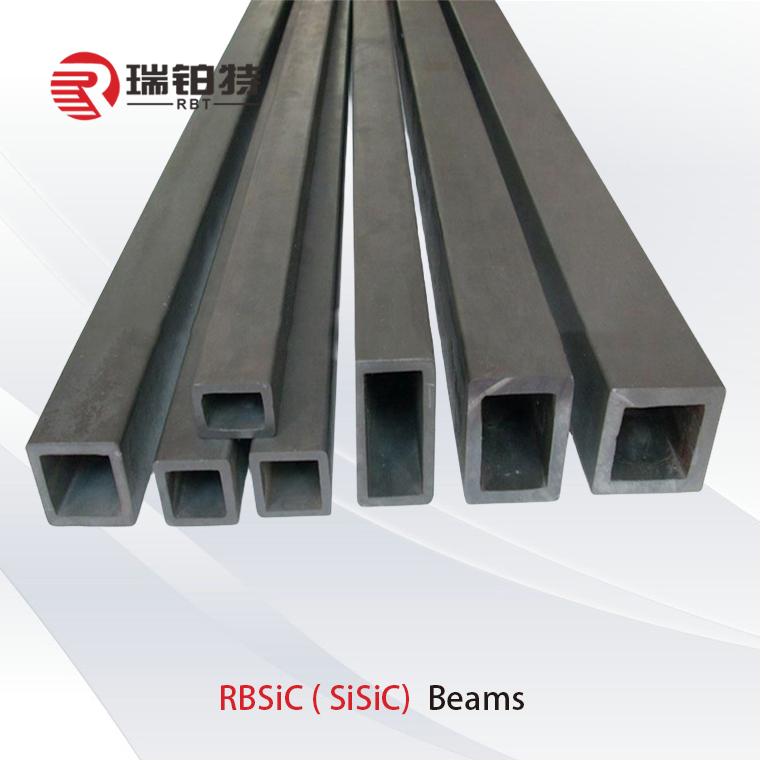

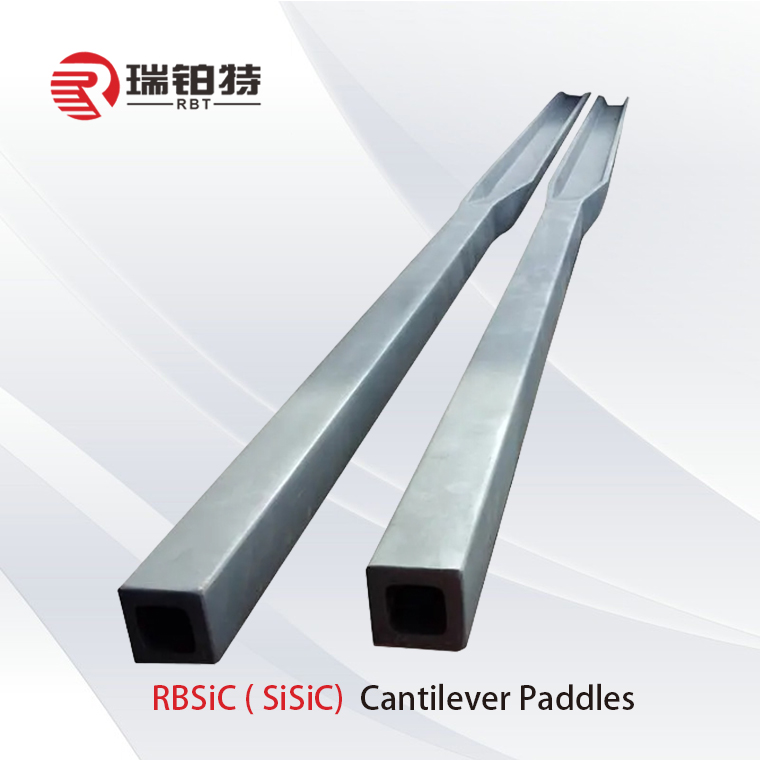

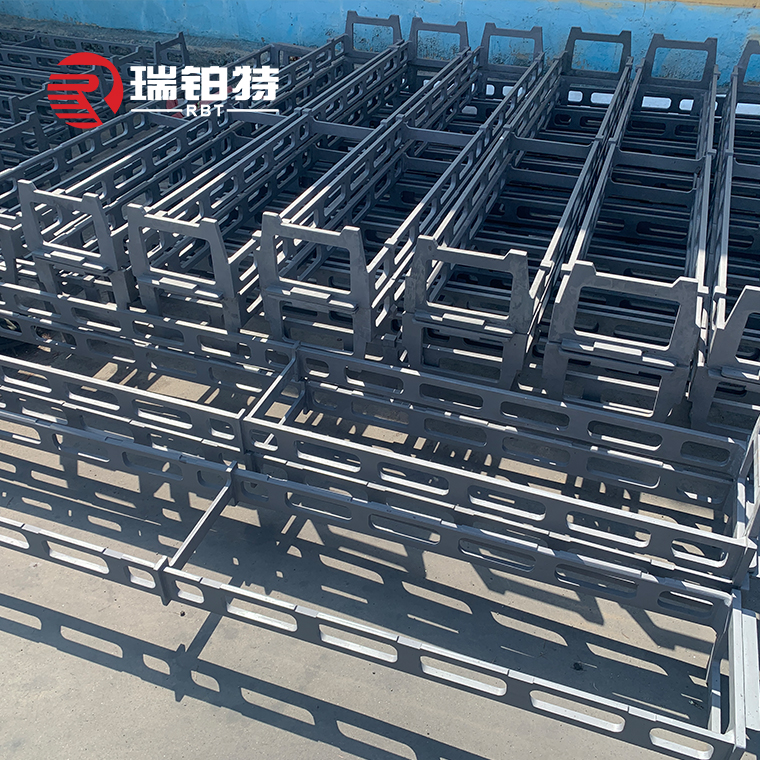

Sebopeho:Silicon carbide square beam e na le melemo ea matla a maholo a mocheso o phahameng, conductivity e ntle ea mocheso, ho hanyetsa mocheso o phahameng le ho boloka matla.Ke sebōpi se loketseng bakeng sa sebōpi sa lithium electric roller rod kiln, elektroniki ceramic powder, sanitary ware, ceramics letsatsi le letsatsi, porcelain ea motlakase, thepa ea refractory, ceramic ceramics le liindasteri tse ling.

| Ho Jara Bokhoni ba Mabala a RBSic(SiSiC). | ||||||

| Boholo ba Karolo (mm) | Lerako Botenya (mm) | Kenyellelitsoe Loading(kg.m/L) | Tlamelo e Abuoang ka Ka mokhoa o Tšoanang(kg.m/L) | |||

| B Lehlakore | H Lehlakoreng | W Lehlakore | H Lehlakoreng | W Lehlakore | H Lehlakoreng | |

| 30 | 30 | 5 | 74 | 74 | 147 | 147 |

| 30 | 40 | 5 | 117 | 95 | 235 | 190 |

| 40 | 40 | 6 | 149 | 149 | 298 | 298 |

| 50 | 50 | 6 | 283 | 283 | 567 | 567 |

| 50 | 60 | 6 | 374 | 331 | 748 | 662 |

| 50 | 70 | 6 | 473 | 379 | 946 | 757 |

| 60 | 60 | 7 | 481 | 481 | 962 | 962 |

| 80 | 80 | 7 | 935 | 935 | 1869 | 1869 |

| 100 | 100 | 8 | 1708 | 1708 | 3416 | 3416 |

| 110 | 110 | 10 | 2498 | 2498 | 4997 | 4997 |

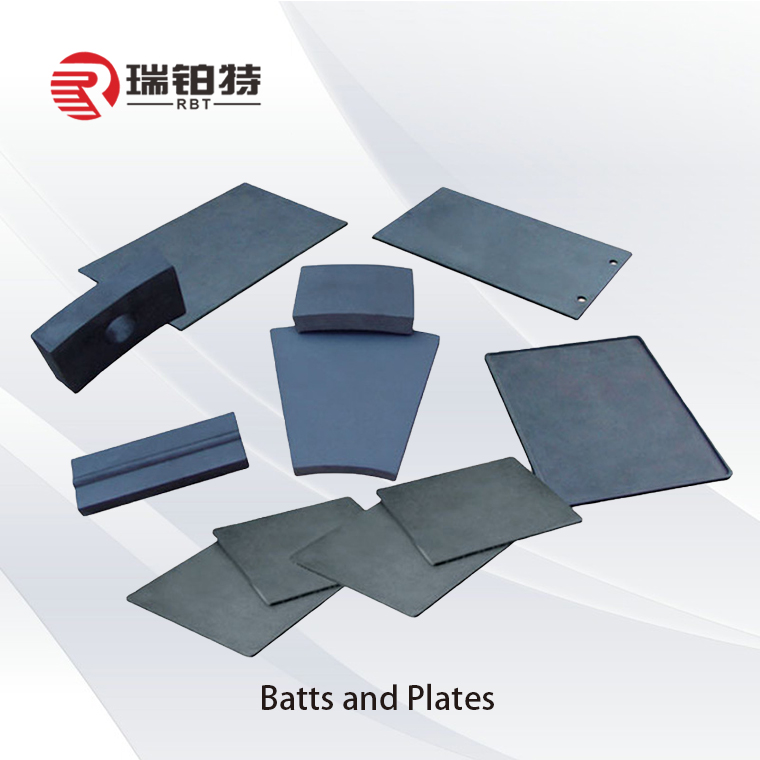

Burner Casing

Radiation Tube

Liner

Tšehetsa

Sephutheloana le Bobolokelo

Lipotso Tse Botsoang Hangata

U hloka thuso?Etsa bonnete ba hore u etela liforomo tsa rona tsa tšehetso bakeng sa likarabo tsa lipotso tsa hau!

Re moetsi oa 'nete, feme ea rona e khethehile ho hlahisa thepa ea refractory ka lilemo tse fetang 30.Re tšepisa ho fana ka theko e ntle ka ho fetisisa, tšebeletso e ntle ka ho fetisisa ea pele ho thekiso le ka mor'a ho rekisa.

Bakeng sa ts'ebetso e 'ngoe le e' ngoe ea tlhahiso, RBT e na le tsamaiso e feletseng ea QC bakeng sa metsoako ea lik'hemik'hale le thepa ea 'mele.'Me re tla leka thepa,' me setifikeiti sa boleng se tla romelloa ka thepa.Haeba u na le litlhoko tse khethehileng, re tla leka ka hohle ho li amohela.

Ho itšetlehile ka bongata, nako ea rona ea ho fana e fapane.Empa re tšepisa ho romella kapele kamoo ho ka khonehang ka boleng bo tiisitsoeng.

Ha e le hantle, re fana ka mehlala ea mahala.

E, ehlile, o amohelehile ho etela k'hamphani ea RBT le lihlahisoa tsa rona.

Ha ho na moeli, re ka fana ka tlhahiso le tharollo e molemohali ho latela boemo ba hau.

Re 'nile ra etsa thepa ea refractory ka lilemo tse fetang 30, re na le tšehetso e matla ea tekheniki le phihlelo e ruileng, re ka thusa bareki ho rala li-kilns tse fapaneng le ho fana ka ts'ebeletso e le 'ngoe.